JS injection molding technology and provides customized material solutions for different industry needs, from high-precision plastic mold design to silicone precisionモールディングは、材料のパフォーマンスの最適化とプロセスイノベーションを通じて、顧客がR&Dの開発サイクルとコストを短縮するのに役立ちます。

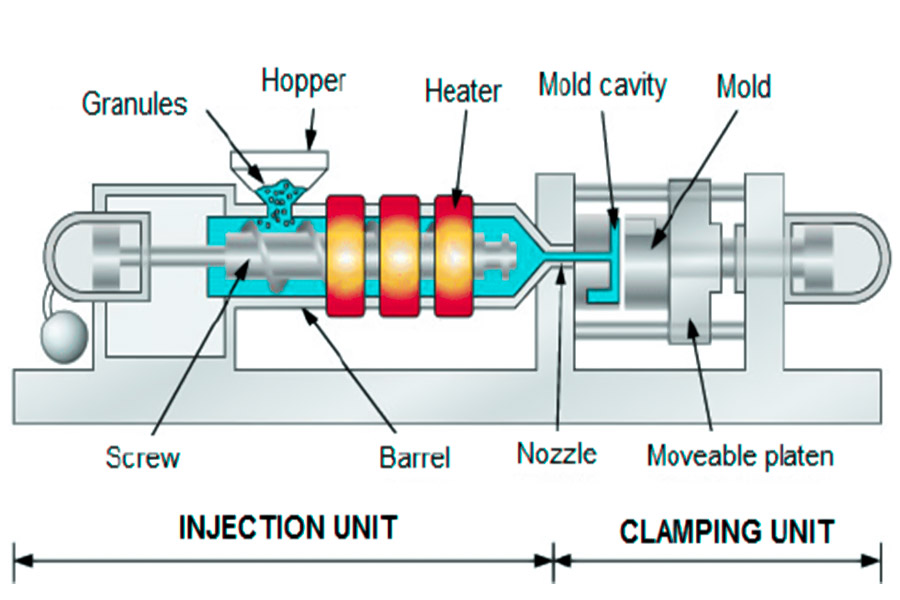

射出成形は、溶融材料が溶けた材料が燃えるようなシリコンなどの溶融材料が設計されている製造プロセスです。固化。 成形設計の正確な構造は、原材料を複雑な形に変換して高効率と一貫性を実現します。 プラスチックモールディングの主要なモールディングも必要ではなく、モールディングのデザインでもありません。標準化されたプロセスを通じて従来の製造で到達するのが難しい薄壁の部品または大量生産。 射出成形とは?

射出成形の重要なステップには、材料融解、材料融解、酸化、硬化後の治療が含まれます。 ダイクーピングまたは自動化のために、耐久性のあるプロセスに対応するための耐久性のあるプロセスに比べて、耐久性のあるプロセスに対応しています。信頼性。

射出成形のコアタイプは何ですか?

1。 data-len = "31" data-v-7b79c893 = ""> 熱可塑性射出成形

熱可塑性ポリマーは溶融状態に加熱されます。

JS Companyは±0.005mm許容制御機能を持ち、複雑な自動車構造を効率的に生産することができます。 ラピッドモールディングテクノロジーは、熱可塑性材料の繰り返し融解特性に完全に適合しており、生産コストを大幅に削減します。

熱セットプラスチックは、不可逆的な化学反応を起こし、高温と圧力下で固化します。 コンポーネント。プラスチックモールディングを通じて高構造強度と化学腐食抵抗を実現するためにカビの設計に依存しています。

液体シリコンゴムは、注入を成形することによりカビに注入され、低温加硫によって成形されます。

多機能統合は、2つ以上の材料(硬質プラスチックマトリックス+ソフト接着剤コーティングなど)を同じ型を介してモールディングを介して編成することで達成されます。

JSの自動化された生産ライン コスト削減の利点は、家電の製造におけるプロセスの実用的な価値をさらに強調しています。

硬いプラスチックや柔らかいゴムなどの2つ以上の材料の成形注入プロセスを組み合わせて、複数のノズルや積み重ねられた注射の成形を介した機能的統合のために、< href = "https://jsrpm.com/industry/consumer-electronics">これは、コンシューマーエレクトロニクスの複雑な構造およびスマートウェアラブルデバイスの複雑な構造で一般的に使用されています。

プラスチックの射出成形は、プラスチックの高温融解に主に使用され、硬質製品を形成します

Data-TranslateID = "1EB5114294A05C9B97D2B95647A2F9A2" data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" " data-translateID = "f18683f788b8f431b594930334b4d8b1" data-pos = "3" data-len = "33" data-v-7b79c893 = ""

data-translateId = "a43dee8a959fd0fb54c8a12a850d4769" data-pos = "0" data-len = "3" data-v-7b79c893 = "">

JS Companyの精密な製造技術とマイクロコンポーネントの射出成形要件によると、重要な機器と技術は次のとおりです。

span class =" date-translateid = "e3726a43e43e43e2a43e2a4d845ep5e145e145e145e255e145e data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 1.i

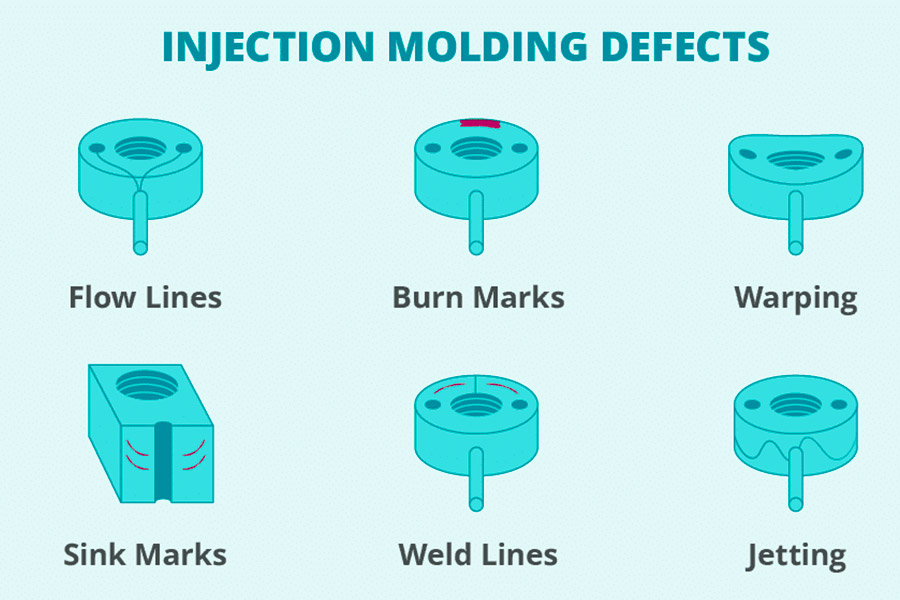

3.Advanced Testing Equipment Unit 4.Automated production systems 5.Special Material Processing Equipment JS company combines micro-injection molding machines, wire cutting equipment and Moldex3D simulation system to form a full-chain technology loop from molding design to precision plastic molding. Typical manufacturing case of micro parts: precision gear injection yield of 0.5mm diameter was 99.2% and dimension tolerance was controlled to ±0.003mm, demonstrating the progressiveness of the equipment system. 1.Material selection and compatibility treatment 2.Mold design and manufacture 3.Injection molding process parameter control 4.Interface integration technology Mechanical interlock design: Design of a concave or inverted structure in a die to improve bonding strength through physical interlocking. Chemical Adhesives Precoating: Special adhesives are sprayed on the surface and cured by injection molding with high temperature activation to achieve molecular level bonding (suitable for dissimilar materials). 5.Quality inspection and reprocessing In the process of injection molding, due to the influence of material properties, process parameters and equipment accuracy, the following technical problems are often encountered: 1.Material shrinkage control 2.Warp and twist 3.quality defects 4.Multi cavity mold balance 5.Risk of material degradation JS company's technological advantages Typical Case Reference Actual results: Injection-molding is the core technology of modern industry. By melting and solidifying molding plastic material, the production of simple rigid member to complex elastic member is diversified. Whether it is the efficient mass production of thermoplastic or the precise flexible molding of liquid silicone, its process adaptability covers many fields such as automobile, medical treatment and electronics. With its ±0.005mm precision mold design multi-material compatible processing, and automated production line integration integration capabilities JS Company continues to push the boundaries of precision and efficiency injection molding field, providing global customers with one-stop solutions from prototype development to mass production, enabling industry transformation and upgrading for high value added and sustainable development. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.The influence of mold temperature on the quality of injection molded parts? The mold temperature is too high, which leads to deformation of injection molding, and the surface roughness or internal stress concentration. Accurate adjustment to material characteristics (e.g. 50-80°C for ABS) are required to ensure size accuracy and appearance quality. 2.What are the commonly used types of injection molding machines? Commonly used injection molding machines types are plunger type, screw type and screw pre-formed plunger type. Among them, screw plastic has become mainstream for its efficiency and energy saving and has been widely used in the mass production of plastic products. 3.What problems can high injection pressure cause? Excessive injection pressure can lead to flash flooding (overflow), increase mold wear, and even lead to deformation or cracking of the product, as well as increased load and energy consumption of the equipment. 4.How to choose suitable injection molding materials? Consider the the product's intended use (PC strength, TPU elasticity), processing temperature and costs such as PP's high temperature resistance, TPU's flexibility, ABS's balance performance and cost. Acrylonitrile butadiene styrene

プラスチック射出成形とシリコン射出成形の違いは何ですか?

寸法の比較

プラスチックモールディング

シリコンモールディング

マテリアルタイプ

熱可塑性物質(例:ABS、PE)または熱硬化プラスチック(例:フェノール樹脂)。

液体シリコンラバー(LSR)は、シリコンゴムシリコーン成形プロセスによって固化します。

プロセス温度

高温での溶融プラスチック(150°C-300°C)。

低温での加硫(60°Cから150°C)。

金型要件

フローチャネルには、高温抵抗、圧力抵抗、精度を備えた冷却システムシステムが必要です。

LSR閉塞を防ぐための広い流れチャネル。

アプリケーションフィールド

自動車部品、電子シェル、商品、その他の剛性製品。

医療カテーテル、シール、ウェアラブルデバイスなどの柔軟な需要シナリオ(シリコンの成形精度に応じて)。 >

後処理

治療せずに除去。

オプションの低温二次除硫は、パフォーマンスを改善するオプションです。

コストと効率

低コスト、大量生産に適しています。

材料単位価格は高くなっていますが、高精度と小さなバッチのカスタマイズ(例:0.005mm許容範囲)がサポートされています。

複雑な構造金型を設計する方法

マイクロパーツの射出成形に必要な機器は?

How to achieve the combination of multiple material injection molding?

What are the common difficulties in injection molding?

Technical difficulties

Industry standard solutions

JS Innovative Solutions

Material Compatibility

Compatible with ordinary plastics only.

Supports more than 50 specialty engineering plastics (such as PEI, PPS, etc.) and provides material modification services.

Formation of microstructures

The minimum feature size is 0.5mm.

Mirror etching mold technology used to achieve batch production of 0.2mm fine texture.

Complex Embedded Assembly

Manual positioning error ≥0.1mm.

Automated embedded positioning system with accuracy ±0.02mm were used.

Environmental compliance

Single material recycling.

Innovative multilayer compound structure separation technology enables efficient regeneration of PET/PC and other hybrid materials.

Fast delivery

The standard cycle is 2-4 weeks.

Digital twin technology reduces the test run time to 7 days and responds to emergency orders within 48 hours.

How can JS reduce injection molding production costs by 20%?

Summary

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.comFAQs

Resources