Instant Quoting

Rapid Prototyping

High-Volume Production

Instant Quotes for Your Stamping Projects

JS delivers quick and precise quotes for all your stamping requirements. With an extensive range of material options, surface treatments, and cutting-edge stamping capabilities, our system ensures you receive competitive pricing and project-ready quotes in just minutes.

50+ Material Options: Carbon steel, stainless steel, aluminum, copper, brass, and more, offering durability and strength to suit a variety of applications.

20+ Surface Treatment Options: Enhance your parts' performance and aesthetics with treatments like plating, powder coating, anodizing, and polishing, with lead times averaging 3-7 days.

Precision Up to ±0.05mm: Ensure high accuracy with tight tolerances for even the most intricate designs.

Get an instant quote today.

Get instant pricing, project lead times, and DFM feedback

STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files

File size: ≤15MB

ITAR Registered

ITAR Registered ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

Trusted by Engineers and Purchasing Leaders at the World’s Most Successful Companies

Stamping

Service

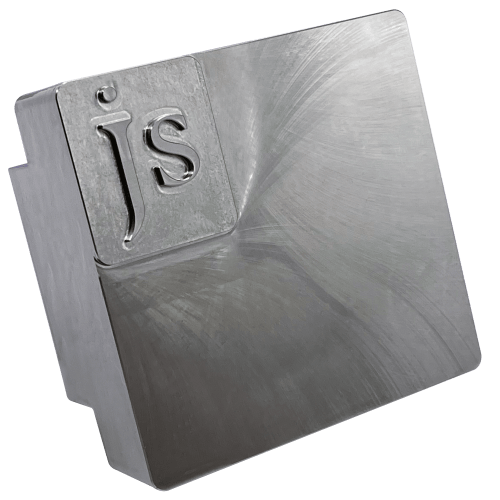

Product Showcase

We specialize in high-precision metal stamping, producing durable parts in various materials for both small and large-scale production. Our expertise lies in forming complex shapes with tight tolerances, ensuring consistent quality and efficient production.

Tolerances

JS specializes in high-precision metal stamping with tolerances of ±0.05 mm to ±0.1 mm. Our advanced processes ensure consistent quality and durability for both small and large-scale productions, meeting your exact specifications for a variety of applications.

Feature

Description

General Tolerances

Metals: ISO 2768-c

Cutting Feature

± .00787" (0.2mm)

Bend Angle

± 1.0°

Bend to Edge

+0.010" (0.254mm)

Bend to Hole

±0.2 mm

Standard Lead Time

3 Business days

Material Selection

JS offers precision stamping using a range of metals, including stainless steel, aluminum, and brass. These materials are selected for their strength, corrosion resistance, and flexibility, ensuring parts that meet demanding specifications and high-quality standards.

Metals

- Titanium

- Steel

- Stainless Steel

- Zinc Alloy

- Chromium-Nickel Alloy

- Brass

- Copper

- Aluminum

- Bronze

- Cold Rolled Steel

- Nickel

- Silver-Tin Oxide

- Cast Iron

Titanium is known for high strength, low weight, and corrosion resistance. We process grades like Ti-6Al-4V, Ti-5Al-2.5Sn, Ti-6Al-4V ELI, and Ti-Grade 2, which are widely used in aerospace, medical implants, and sports equipment.

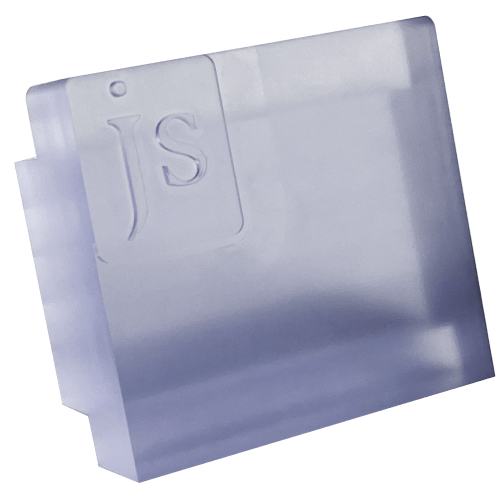

Plastics

- Polycarbonate (PC)

- Polyoxymethylene (POM)

- Polyphthalamide (PPA)

- Polyphenylene Sulfide (PPS)

- Teflon (PTFE)

- Polyvinyl Chloride (PVC)

- Ultra High Molecular Weight Polyethylene (UPE)

- Polyether Ether Ketone (PEEK)

- Nylon (PA)

- Glass-Filled Nylon

Polycarbonate is a transparent, highly durable plastic known for its superior impact resistance. We offer different grades suitable for eyewear lenses, medical devices, and protective equipment.

We offer customization based on your specific material requirements, if you need a material not listed here, our team can source and process ito meet your exact needs

Surface Finishing

Surface finishing plays a key role in enhancing both the appearance and performance of metal stamped parts. JS employs high-precision stamping processes, paired with treatments like deburring, polishing, and coating, to ensure smooth edges, corrosion resistance, and long-lasting durability, all meeting the highest industry standards.

Advantages & Features

Our stamping services deliver high precision, efficiency, and scalability for producing high-quality metal parts. JuSheng offers advanced stamping solutions that cater to various industries and applications, ensuring consistent and reliable results. Here’s why we are the ideal partner for your metal stamping needs.

Case Studies

JS's metal stamping services cater to a wide array of industries, providing customized solutions that meet the unique challenges of each sector. Below are examples that showcase how we’ve supported clients with high-precision, reliable, and cost-effective metal stamping solutions:

Quality Control

At JS, we prioritize strict quality control at every stage of the stamping process. Our combination of advanced stamping techniques and a robust quality assurance system ensures that every component is produced to the highest standards of accuracy and reliability, tailored to meet the needs of a variety of applications.

In-Process Inspections

Before any part leaves our facility, it undergoes a thorough final inspection. We use advanced measurement tools to verify that every component meets required specifications and precision standards, ensuring the highest level of quality before delivery.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

We use cutting-edge measurement tools such as Coordinate Measuring Machines (CMM) and optical comparators to ensure precise measurement of dimensions and tolerances. These tools allow us to maintain high accuracy throughout the stamping process, ensuring the final product meets the highest quality standards.

Certified Quality Standards (ISO 9001, ISO 14001, IATF 16949, AS9100D)

Our commitment to quality is backed by ISO 9001 certification, which ensures our quality management system is consistently effective and continually improving. We also adhere to ISO 14001, IATF 16949, and AS9100D standards, ensuring we meet the needs of various industries while maintaining environmental sustainability and operational excellence.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Contact Us for More Information

Should you have any additional questions or require more details, feel free to reach out to us. Our dedicated team is ready to assist you with all your precision manufacturing requirements.

We understand that you may have questions about our stamping services. Below are some of the most frequently asked questions, with detailed answers to help you understand our capabilities and processes. If you need additional assistance, our team is always ready to support you.

Customer Testimonials

JS excels in providing high-quality stamping services, delivering precise metal components for various applications. Here’s what some of our clients have to say about their experience working with us:

Latest News

Stay informed with the latest updates and announcements from JS. Learn about our most recent projects.