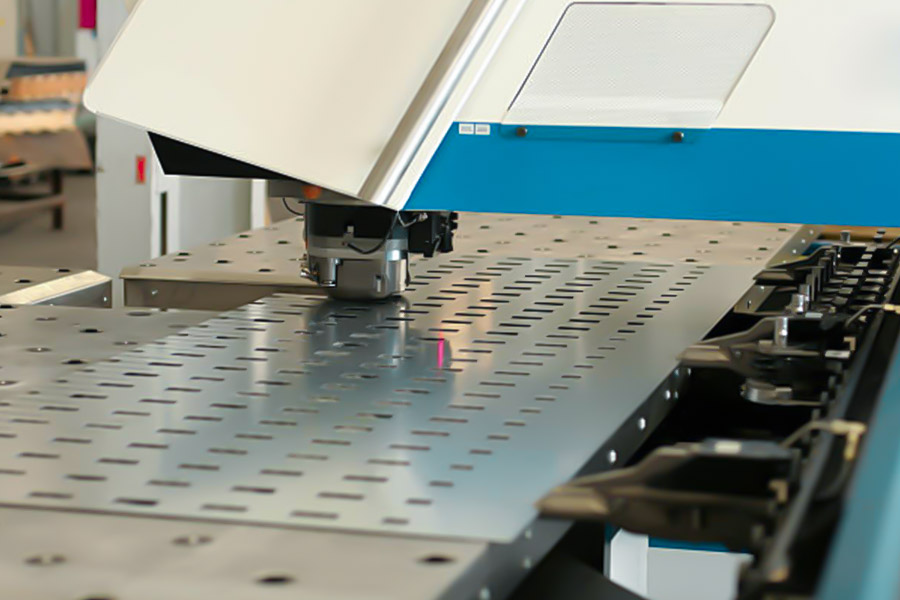

金属スタンピングは、金属シートをダイとプレスを通じて効率的に処理できる一種の製造技術です。コアは、メタルスタンプを使用して、スタンピング金属に圧力をかけることにあります。このプロセスには、高精度、高効率、低コストの利点があり、近代的な工業製造のコアテクノロジーの1つになりました。複雑なジオメトリやマイクロメーターレベルの許容要件に関係なく、金属スタンピングは、多くの注文の配信需要を満たすために、自動生産ラインによって安定して生成できます。 JS Companyの高精度の金型とインテリジェントな機器、スタンピングプロセスの信頼性をさらに向上させ、顧客が製品開発のサイクルを短縮し、コスト削減効率を達成するのに役立ちます。

金属スタンピングとは?

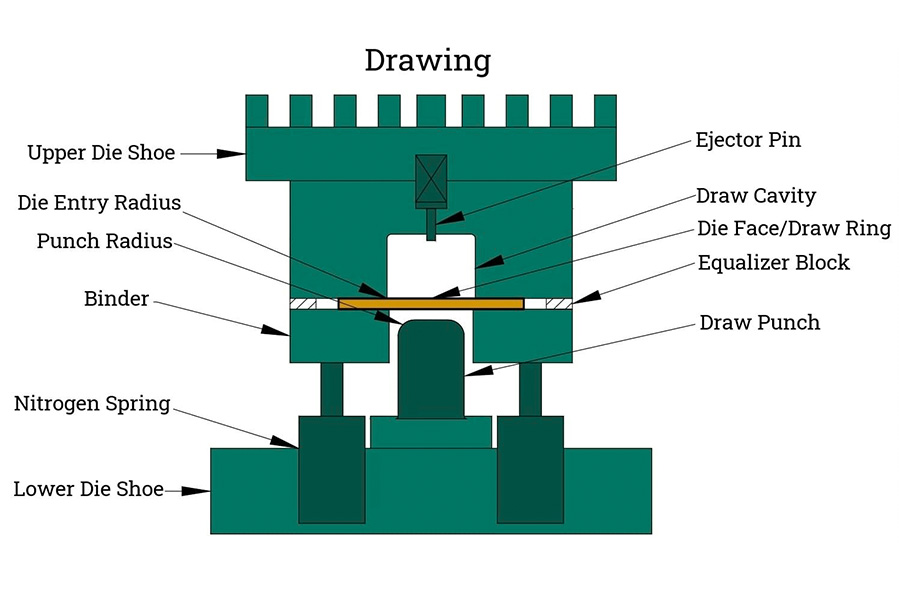

金属のスタンピング方法

スタンピング金属 手順:

1。 Data-TranslateID = "26A16BF47DDE9690927D307FBF240C76" data-pos = "3" data-len = "27" data-v-7b79c893 = "">

Data-TranslateID = "489EDFFF1918DCE18A1C765C6933752E" data-pos = "0" data-len = "3" data-v-7b79c893 = "">

3。 data-translateId = "a98b27d73cd5dd899b0d2bccbd7651aa" data-pos = "3" data-len = "26" data-v-7b79c893 = ""> シートメタルをダイに押し込み、プレスを押して、順番にスタンピング、曲げ、伸縮プロセスを完了します。 4。 Data-TranslateID = "05EC4B0842EBEB295B478C2BD5439E65" DATA-POS = "3" DATA-LEN = "35" Data-V-7B79C893 = ""> スタンピング後、バリを削除する必要があります。

data-translateId = "5D91FE408BC333E6E1DC18D8E6FD0C5C" DATA-POS = "0" data-len = "3" data-v-7b79c893 = "" 17px; "> "">最適化

スタンプ金属は電子コンポーネント。 大量生産は満たすことができます。

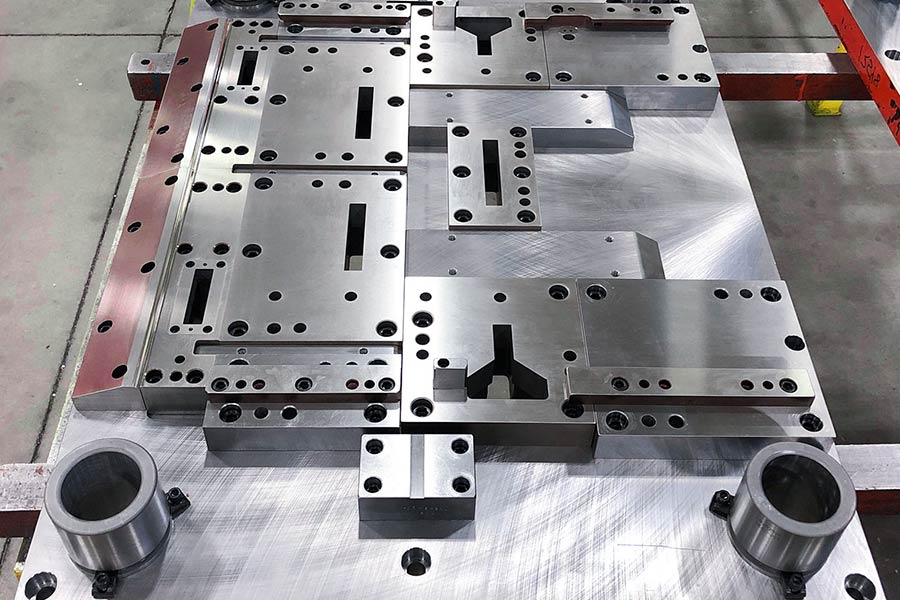

金属スタンピング金型を選択する方法

1。 data-len = "29" data-v-7b79c893 = ""> 金型材料パフォーマンス

金属スタンパーの材料は、サービスの寿命とシュタンパーの加工精度に直接影響します。 加工された金属の延性。

2。 data-len = "29" data-v-7b79c893 = ""> スタンピングプロセス要件

3。 data-len = "33" data-v-7b79c893 = ""> 生産バッチとコスト残高

高コストの長寿命金型(セメント炭化物金型など)は大量生産に優先されますが、お金のためのより良い価値のあるツール鋼型金型は、href =" https: "生産。

4。 data-len = "35" data-v-7b79c893 = ""> 金型精度と耐性制御

精密コンポーネント(電子コンポーネントなど)には、通常の構造コンポーネントの耐性が緩和されるのは、±0.05mm

5。 data-pos = "3" data-len = "26" data-v-7b79c893 = "" "> サプライヤーのテクニカルサポート 提案を選択 プロセス: Data-TranslateID = "E1457820D3ECAEDB1226E4CBEB8C63B4" data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 1。 Data-TranslateID = "9A85CD6523FEE3D4B7A4457DFC54A4A2" data-pos = "3" data-len = "22" data-v-7b79c893 = "">

曲げ

仕上げ data-translateId = "a77173d6ddd82652416f6963b4ee4728d" data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" " data-translateId = "cfa1fa33fed860d900bf0d5108e3dc82" data-pos = "3" data-len = "35" data-v-7b79c893 = "">

<"> < data-translateId = "a4a141a6af670cefc43260befd87c3e2" data-pos = "0" data-len = "3" data-v-7b79c893 = "">

Main Effect of Material Hardness on metal stamping 1.Mould wear rate 2.Adjustment of stamping process parameters 3.Quality of finished products and tolerance control 4.Material Applicability Limitations Comparison of stamping process of Different Hardness materials The die has a service life of less than 100000 times and is very expensive. Dimensional accuracy ±0.02mm requires 3D inspection. 1.Improving accuracy and reducing waste High-precision equipment and technology: Automated production and intelligent detection: Automatic stamping equipment is combined with real-time quality control system to reduce manual intervention errors and improve yield rates. 2.Material management and selection strategy Adaptability of a variety of materials: Use JS's metal material database of metal materials (such as stainless steel, aluminum alloy, copper alloy, etc.) to select the most cost-effective materials based on product performance and avoid overdesign. Residual material recycling and nesting technology: Maximize board utilization (15%-20% increase in JS's material utilization rate) through intelligent typesetting algorithms, reduce corner material waste, and support the recycling of materials such as aluminum and steel. 3.Process efficiency and rapid response Standardized and modular design: Provides a standardized metal punch library (connectors, casings, etc.) to shorten design lead times, and supports customers to customize quickly to existing templates to reduce development costs. Agile production mode: Commit to 1-2 weeks of standard delivery time (including complex orders) and reduce additional costs for emergency orders through lean production management and priority scheduling. 4.Collaborative design and process collaboration Early intervention in client design: The JS team provides pre-design review services to optimize the structural strength, tolerance fit, and assembly feasibility of metal punch to avoid additional costs associated with later modifications. Mold sharing and lifecycle management: Provide long term maintenance and optimization services for high frequency order molds, extend the lifespan of molds (the average life of JS molds is 30% longer than industry standard), and dilute unit cost of individual products. 5.Sustainable production reduces costs and improves efficiency Green manufacturing certification: Energy energy consumption has been reduced (JS energy consumption has been reduced by 15%) through the implementation of the ISO 14001 environmental management system and the introduction of energy-efficient stamping equipment and renewable lubricants. Reduce process and logistics costs: Provide Design stamping surface processing one-stop service (JS integration capability covers the entire chain), eliminating intermediate costs. Cutting-edge equipment and precision machining technology 1.Ultra precision stamping equipment 2.Mold design and manufacture Intelligent process control systems 1.Real-time quality monitoring 2.Adjustment of material properties Match the best material grade (e.g. Al6061) and thickness (0.1-5mm) to the application of metal punch (e.g. automotive sheet metal and electronic components) to avoid rebound or cracking due to insufficient material ductility. Full-process quality management system 1.ISO 9001 and IATF 16949 certification 2.Reverse engineering and rapid feedback For accuracy of customer feedback, the failure analysis is carried out using coordinate measuring machine, and the improvement scheme is provided within 48 hours to shorten the debugging cycle. Metal stamping is the core technology of modern industry, which can effectively transform metal sheets into high-precision metallic stamps. Process flow includes design optimization, material adaptation, mold manufacturing, stamping production and reprocessing, each step requiring strict tolerance and deformation control. The hardness of the material directly influences the wear and tear of the die, the selection of process adjustment parameters and the quality of the finished product. With ultra-precision its ultra precision stamping equipment mold technology full process quality management system JS Company ensures that metal stamping tolerance is controlled to ±0.005mm and material utilization is increased to over 92%. At the same time, it reduces energy consumption and waste through sustainable manufacturing practices. Providing efficient, reliable and cost-effective solutions for manufacturing highlights the irreplaceable role of metal stamping in precision manufacturing. このページの内容は情報目的のみです。サードパーティのサプライヤーまたはメーカーがJushengネットワークを介して提供するパフォーマンスパラメーター、幾何学的許容範囲、特定の設計機能、材料品質と種類または仕上がりがあると推測すべきではありません。これはバイヤーの責任ですこれらの部分の特定の要件を決定するために、パーツの引用を求めてください。

jsは業界をリードする会社ですカスタム製造ソリューションに焦点を当てています。 5,000人以上の顧客にサービスを提供している20年以上の経験により、高精度 cnc machining 、 1.What tools are needed for metal stamping? Includes high-precision die, press, tool, lubricant, clamping devices, quality inspection equipment, etc. Mould ensures accuracy of shape, press provides punch pressure, tool completes cutting, lubricant reduces friction, fixture fixed plate, test equipment ensures consistency of dimensions. 2.What materials are suitable for stamping? Common materials include stainless steel, aluminum, copper, steel plates, etc. Thickness (0.1-5mm) and strength shall be selected according to the purpose of the product, taking into account ductility, corrosion resistance and cost requirements. 3.Do stamped parts need additional processing? Stamped parts usually require burr removal, polishing, or surface treatment to improve appearance, rust resistance, or functional compatibility. Treatment depends on the product's purpose, for example, electronic components require high-precision polishing and automotive parts often require anticorrosive coatings. 4.What are the consequences of stamping metal too fast? High speed stamping may cause material tearing or mold impact damage due to inertia. Normally, stainless steel stamping speed is controlled at 50-80 times perminute, while aluminum can be ramped up to 120 times perminute, depending on the malleability of the material.

考慮要因

ハードアロイ型

ツールスチールカビ

ポリマー材料カビ

該当する材料

ステンレス鋼やチタン合金などの高硬度金属。

アルミニウムや銅などの低〜中の強度の金属。

薄いアルミニウムシート、プラスチック複合パネル。

ライフサイクル(スタンピングサイクルの数)

1,000,000以上。

500,000-800,000回。

100,000回以内。

コスト

high(高い材料と処理コスト)。

medium

low

処理精度

±0.005mm(精密コンポーネント)。

±0.01mm

±0.1mm

該当するシナリオ

自動車エンジンコンポーネント、精密コネクタ。

家庭用アプライアンスシェル、ヒートシンク。

小さな装飾品、一時的なサンプル。

金属スタンピングプロセスのシーケンスを配置する方法

金属スタンピングに対する物質硬度の影響は何ですか?

Material hardness (HRC)

Typical materials

Stamping process challenge

Key points of quality control

<HRC 20

Low carbon steel, pure aluminum.

Large rebound and poor dimensional stability.

Increase leveling process or overbending compensation design.

Tolerance ± 0.1mm, no scratches on surface.

HRC 20-35

Stainless steel (1Cr18Ni9Ti).

Mould wear quickly, surface easy to scratch.

Use PVD-coated moulds with lubricating oil to assist stamping.

Ra≤0.8μm, No burrs.

HRC 35-50

Spring steel, tool steel.

Stamping crack risk is high and the ductility reduced.

Multi step progressive stamping+intermediate annealing treatment.

Elongation rate ≥15%, no fractures.

>HRC 50

Titanium alloy, hard alloy.

Diamond coating mold, composite stamping process.

How to reduce the cost of metal stamping?

How does JS company ensure the accuracy of metal stamping?

Summary

免責事項

jsチーム

FAQs

Resources