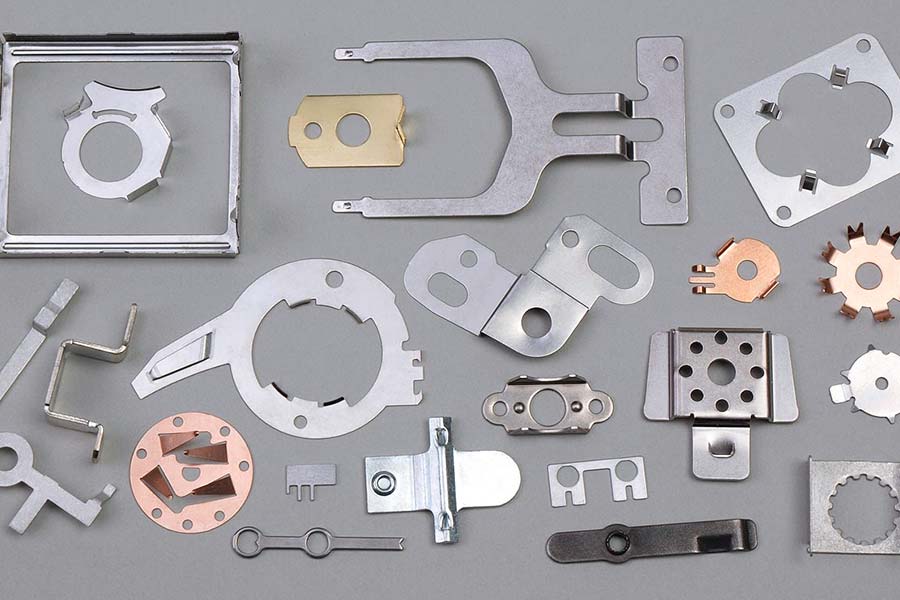

Основной принцип штамповки металла состоит в том, чтобы использовать высокую форму для нажатия , сгибание или растяжение металла в определенную форму, с преимуществами высокой эффективности, низкого потребления и хорошей консистенции. Metal stampings is widely used in various industries from simple structure parts manufacturing к сложной структуре производства, что доказывает необратимость этого процесса в современной промышленности. In this basic guide, we will further explore the advantages, процессы, типы оборудования и требования к применению металлической штамповки в различных отраслях.

1. Точность и согласованность

Metal Stamps Плесень принимает технологию обработки CNC, Толерантность ± 0,005 мм, «Процесс Mass Oin Producation IN IN SPAN Production IN The Producation Oin. Высокий.

2. Производительность

Metal Mathmps Ploms можно быстро переключаться, и с помощью автоматических прессов устройство может производить сотни частей в час, что делает его в частности 3.cost Преимущества

плесень может быть повторно использована тысячи раз, разбавляет единичные затраты с течением времени и достигает скорости использования материалов более 85%. ">" СОЗОБЛЯТЬСЯ С СНАН-V-7B79C893 ". Для материалов высокого значения, таких как алюминиевые сплавы и нержавеющая сталь.

4.complex formeforce Processing

Через несколько прогрессирующих форм процесс удара, изгиба и растяжения может быть завершен в одном href = "https://jsrpm.com/industry/automotive"> батарейные лотки новых энергетических транспортных средств .

5.Cross-industry adaptation

metal штампы Поддержка Custom Designs , от титальных компонентов для Medical Deavices до Aerospae Tittan Tittin Litting Pronding Pronding Pronding Pronding Plate Plate Plate Plate Plate Plate Plate Plate Tittin Регулируя параметры плесени.

Что является базовым процессом металла. штамповка?

1.design и" " Создание

после того, как клиент подчиняет файлы CAD, как это требуется, href = "https://jsrpm.com/about-us> jscut-us Опыт оптимизирует схему проектирования, чтобы обеспечить соответствие требованиям точности штамповки. Они используют расширенное программное обеспечение для разработки высокопроизводительных металлических форм, которые соответствуют строгим спецификациям, требуемым клиентами.

2. Выбор материала и резка

в соответствии с инженерными требованиями, из более чем 50 металлических материалов (таких как нержавеющая сталь, алюминий, медь и т. Д.), Чтобы выбрать соответствующую тарелку.

3. data-translateid = "3EA67125A5020A85921C94285FF20887" data-pos = "3" data-len = "27" Data-V-7B79C893 = ""> High-Speed Camping

В автоматическом оборудовании штамповки, штамповка, изгиб, растяжение и другие процессы завершаются в одном штампе в процессе металла. интеллектуальная производственная линия JS обеспечивает быструю доставку за 1-2 недели , с повышением эффективности 20%, особенно для объемных заказов.

4. Обработка поверхности и качество проверки

После штампования обеспечить удаление заусенца, покрытие, опрыскивание и другие услуги с добавленной стоимостью. JS uses more than 30 quality inspection standards, combined with Система проверки видения искусственного интеллекта, до более 98% квалификации продукта и снижение переделки.

Используя систему утилизации отходов, потребление энергии в процессе штамповки снижается на 15%, что отвечает требованиям защиты окружающей среды. «Продолжительность js in 25%, js in 25%, js in 25%, js in 25%, js in the in data-V-7B793 ="> "js in data-v-7b79c893 ="> ". Заказы.

1. Оборудование для гидравлической штампы: управляется гидравлической системой, подходит для махинации больших металлических листов и обычно используется в производстве автомобилей или тяжелой машины или тяжелой машины или тяжелой машины или тяжелой машины. Структура.

Оборудование для гидравлической штампы: Гидравлическая система обеспечивает стабильное давление, подходящее для штамповки металлических заданий, требующих высокой точности, такой как формирование автомобильных балок и конструкции тяжелых машин. «ДАВЛЕНИЕ ДАВЛЕНИЕ ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНО ВОЗМОЖНОМ ДАННЫМ КОМПЛЕКТАЦИИ ВОЗМОЖНОГО ДАННОГО ДАННЫХ ДАННЫХ ДАННЫЕ В-7B793. пластина.

3. МЕХАНИЧЕСКАЯ ПРЕСПАСА: управляемый механизмом соединительного шатуна коленчатого вала, Подходит для высокоскоростного производства металлов с большим металлом , такого как домашний примененный оболочек, 3C-span Span Span Span Span Span Span Span Span Span Span Span Span Span Spopet, и т. Д. Class = "Предложение" data-translateId = "0E36ED8923C6B8F1EC8D815364B2FA4E" DATA-POS = "186" DATA-LEN = "78" DATA-V-7B79C893 = ">

5. Прессы штамповки: Использование сервис-двигателей для точного управления ходом штамповки и давления, он подходит для штамповки металлов алюминия, магния и других материалов, и может сохранить более 30% энергии, чем традиционное оборудование.

6.

7. MANGINE: Это обычно используемый метод при складывании или трехмерной структурной обработке листов листовых металлов для достижения изгиба и формирования через пресс.

1. Принципы процесса

- ". нажимать.

- Изготовление листового металла в основном включает в себя резку, изгиб и сварку , постепенно формируясь через оборудование для резки или изгиба, часто используемое в простых конструкциях, таких как оболочка шасси.

2. Оборудование и зависимость формы

- Металлическая штамповка по зависимости от Metression Metallic Metallic и Professional Press , которые будут наносят в формировании. раз.

- "/"Span". Использует лазерные машины с ЧПУ, изгибающую машину и другое общее оборудование, не нужно настраивать умирание, поэтому обладает высокой гибкостью.

- Металлическая штамповка реализует сложную структуру посредством глубокой пластической деформации и требует высокой материала материала.

- листовой металл " span ">" v-7b797a7 ". class = "предложение" data-translateid = "c9f07ec5b158500d898f8a8fb17dddd28" data-pos = "0" data-len = "189" Data-V-7b79c893 = ""> Изготовление является в основном кольцо или нарезание, подходящая для производства. Части.

4.Efficiency and cost

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100,095%; ширина границы: 1px; пограничный цвет: #000000; высота: 377,938px;" border = "1">5 DATA-LEN = "15" DATA-V-7B79C893 = ""> Качество поверхности

- штамповка металлов может быть достигнута с помощью Metallic Stamp с топонерами на уровне микрометра (± 0.01mm) и гладкая обложка.

- Потому что листовой металл изготовление в мультипроцессном сплайсинге может показаться небольшими ошибками допуска сустава.

In short, metal stamping is a subtractive+plastic forming technology driven by metallic stamp, while sheet metal fabrication is a combination of cutting and bending, which complement each other to meet the needs of different industries.

What are the applications of combining composite materials with metal stamping?

1.Car lightweight components

- Application: JS helps car companies reduce weight by more over 30% maintaining crash collision safety combining metal stamping structural components, such as frame crossbeams, with carbon fiber composites. Metal stamping parts are formed by a metal stamp process that provides high rigidity support in key areas, while composite material covers non-bearing areas to reduce overall weight.

- Technical highlights: JS's CNC machining technology can accurately control the tolerance (±0.005mm) of metal punch to ensure seamless connection with composites and reduce assembly Ошибки.

2.Aerospace heat resistant components

- Application example: A satellite project combines titanium alloy punch and ceramic matrix composites for use in rocket engine nozzles. Metal stamping parts can withstand high temperature and pressure environment, while the outer layer of composite material provides thermal insulation.

- Technical highlights: JS's automated production line can complete metal stamping and composite material coating at the same time, shorten the production cycle to 60% of traditional processes and achieve a yield rate of 98%.

3.Consumer electronics cooling module

- Application example: The high-end smartphone heat sink adopts the aluminum alloy stamping frame and graphene composite integrated design. Metal stamping parts are processed by metal stamp technology to ensure the electromagnetic shielding performance of the finished product, while composite materials effectively conduct heat.

- Technical highlights: JS's precision machining technology can achieve 0.02mm of micropore processing to meet the density requirements heat dissipation holes, while reducing overall thickness by 0.5mm through material composite.

4.Medical devices

- Application example: Stainless steel stamping frame and PEEK composite material for external fixation support of orthopedics. Metal stamping parts provide precise support, while composite materials reduce weight and prevent X-ray interference.

- Technical highlights: JS's flexible manufacturing system supports small volume customization of production, up to 7 working days from design to delivery, and serves multiple international medical device manufacturers.

5.New energy storage systems

- Application example: The battery shell adopts the composite structure of aluminum magnesium alloy punch and fiberglass composite to ensure mechanical strength and improve corrosion resistance.

- JS's process can reduce the weight of the casing by 18% while improving battery life through simulation.

What are the requirements for stamped parts in medical devices?

The medical device industry has extremely strict requirements for the performance, accuracy and safety of metal stamped parts, which must meet the following key standards:

1.Material biocompatibility

- Metal stamped parts shall use medical-grade materials (e.g. 316L stainless steel, medical polymer materials) to ensure non-toxicity, corrosion resistance and biocompatibility in accordance with ISO 10993 standards.

- For example, Stamping part of an orthopedic implant needs to be cytotoxicity and sensitization tests to avoid rejection reactions.

2.Dimensional accuracy and surface smoothness

- Metal stamped molds must have tolerances ±0.01mm and surface roughness Ra ≤0.4μm to avoid scratching tissue or affecting instrument function.

- Example: The incision of the surgical forceps needs to be polished to achieve a mirrored effect and prevent tissue from sticking during surgery.

3.Aseptic and clean production

- Stamping is completed in a dust-free workshop (stage 1000), and metal stamped parts need to be cleaned, passivated and sterilized (e.g. ethylene oxide or irradiation) to ensure no residual contaminants.

- For example, stamping part of heart stents must comply with the ISO 13485 cleanliness standard to avoid the risk of blood clots caused by particle contamination.

4.Surface functionalization treatment

- Through PVD coating and micro arc oxidation, the abrasion resistance or antimicrobial resistance of metal stamped parts can be enhanced to meet special clinical needs.

- Example: Endoscopes are coated with a titanium nitride layer to reduce friction coefficient and inhibit bacterial growth.

5.Accreditation and traceability

- Metal stamped parts must comply with regulations such as FDA 21 CFR Part 820 and CE MDR, and provide complete production batch records and documentation of material traceability documents.

- Example: Disposable syringe stamping parts need a unique serial number to support full lifecycle traceability.

Technical difficulties and solutions

| Challenge | Metal stamped response plan |

| Complex shaped parts forming | Multi station progressive die+servo press to achieve micrometer level precision control. |

| Ultra thin material processing | Nitrogen assisted stamping process is used to reduce the rebound of aluminum/titanium alloy sheets. |

| High frequency sterilization tolerance | Optimize the surface coating process of mold surface and improve the corrosion resistance and fatigue resistance of stamped parts. |

What are the restrictions on stamping materials for engine blades?

1.High temperature stability

Leaves need to work in a high temperature (800°C to 1100°C) gas environment for a long time, the material needs to resist creep, oxidation and low thermal expansion coefficient.

- Typical materials: Nickel based superalloys (such as Inconel 718), titanium alloys (Ti-6Al-4V).

- Technical response: JS company uses vacuum heat treatment and surface coating (such as DLC or ceramic coating) to improve the material's high temperature resistance.

2.Mechanical strength and fatigue life limitations

- The blades need to withstand centrifugal force, vibration, and thermal stress, and the materials need high yield strength (≥800MPa) and excellent fatigue resistance.

- Typical materials: ultra-high strength steel (e.g. Maraging Steel), directional solidification alloys.

- Technical response: JS's precision stamping equipment achieves micrometer level tolerance control (± 0.005mm), reducing the risk of stress concentration.

3.The contradiction between lightweight and specific strength

- Density must be reduced while maintaining strength to increase the thrust to weight ratio of the engine.

- Typical materials: Titanium alloy, carbon fiber reinforced composites (CFRP).

- Technical response: JS adopts topology optimization design to embed lightweight composite reinforcement ribs in metal stamping parts to reduce weight by over 20%.

4.Material processability limitations

- High-strength materials, such as nickel alloys, have severe job hardening and are prone to cracking, while titanium alloys exhibit significant knife stabbing.

- Technical response: JS uses gradient stamping technology, combined with professional lubricating oil and multi-process forming technology, to reduce the risk of material tearing.

5.Corrosion resistance and oxidation limitations

- Sulfide and chloride in gas can easily cause material corrosion and shorten blade life.

- Typical material: Corrosionresistant alloys such as Hastelloy X, surface nitrogen treatment.

- Technical response: JS's precision cleaning and passivation process can remove stamping residue and combine with anodic oxidation to improve corrosion resistance.

How does JS's material library match the needs of the automotive industry?

Core advantages of JS material library

1.High-strength and lightweight materials

- Typical materials: 6 series/7 series aluminum alloy, titanium alloy, carbon fiber composite.

- Application scenarios: Body coverings, battery pack Case, suspension system Component.

- Strengths: 30%-50% weight loss, improvement, a tensile strength over 600MPa.

2.Corrosion resistant and high-temperature resistant materials

- Typical materials: 316L stainless steel, 625 heat resistant alloy, PEEK plastic.

- Application scenarios: Exhaust system components, high temperature bracket for electric drive system, fuel cell bipolar plate.

- Strengths: Spray corrosion resistance of more than 2,000 hours, long-term working temperature up to 300℃.

3.Precision processing specialized materials

- Typical materials: Copper alloy (C18150), mold steel NAK80, optical grade PMMA.

- Application scenarios: Sensor precision Shell, motor gears, car light reflectors.

- Advantages: Processing tolerance ±0.005mm, surface roughness Ra <0.4μm.

4.Environmentally friendly and sustainable materials

- Typical materials: Recycled PA66, biobased PLA, low VOC ABS.

- Application scenarios: Interior, charging station housing, child safety seats, etc.

- Strengths: Reduced carbon emissions by 40% and EU RoHS certification.

Material solutions for the automotive industry

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1">Differentiation in JS

- Technology integration capability: Seamless integration CNC machining, 3D printing, surface processing and other technologies to achieve integrated manufacturing of complex parts.

- Materials Database: A physical/chemical performance database covering more than 50 materials that supports the selection of AI assisted materials.

- Sustainability certification: 100% material traceability through IATF 16949 and ISO 14001 system certification.

Summary

Metal stamping, as the cornerstone process of modern industry, has permeated dozens of fields such as automobile, electronics, healthcare, aerospace and so on. Regardless of the type of complex and irregular structures, stamp metal technology achieves one-off molding of complex structures by balancing strength, precision and cost efficiency through the synergy of high-precision molds and presses.

In the future, as smart factories and green manufacturing advance, stamp metal will continue to define the limitless possibilities of industrial manufacturing in an efficient and low-carbon manner.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.What is the definition of metal stamping?

The process of manufacturing parts by applying pressure on metal materials by mould and press is characterized by high precision and high efficiency.

2.Key points of stamping mold design?

In order to optimize processing cost and production efficiency, attention should be paid to reasonable structure, material strength and abrasion resistance, accurate control of suitable clearance and slope removal, and ensure stamping accuracy, mold life and operation safety.

3.What are the characteristics of aerospace stamping parts?

High-strength and lightweight materials (titanium alloy/hyperalloy), precision molds, multi-process stamping are required, with high temperature resistance, high pressure resistance, micrometer level tolerances, lightweight structure, etc.

4.What are the application fields of metal stamping?

Widely used in automotive, electronics, home appliances, medical, aerospace, new energy, construction, manufacturing structural components, precision parts, lightweight components and other fields.

Resources