o que é moldagem por injeção?

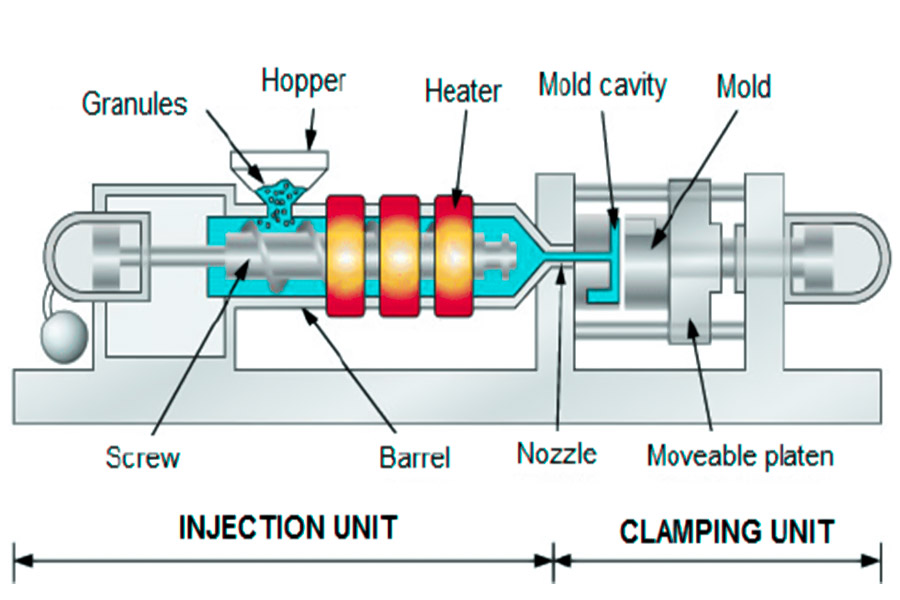

Injection molding is a manufacturing process in which molten materials (such as plastics or liquid silicone) are injected at high pressure into a finely designed mold cavities and cooled and solidificado. A estrutura precisa do design de moldagem para transformar matérias-primas em formas complexas para obter alta eficiência e consistência . As the mainstream technology of plastic molding, it is not only an important carrier of molding design, but also solves the need of precision structure, Peças de paredes finas ou produção em massa, difícil de alcançar na fabricação tradicional por meio de processo padronizado.

sua vantagem técnica para se adaptar a seda moldagem por injeção de plug-in. Compared with die-casting or blow molding processes, it can meet the requirements of material diversification and automation, and has significant advantages in cost control and Confiabilidade do produto.

Quais são os principais tipos de moldagem por injeção?

1. span Class = "sentença" data-translateId = "55B63F2068629C0DDDDD1F3EDEID60. data-len = "31" data-v-7b79c893 = ""> moldagem de injeção termoplástica

Polímeros termoplásticos são aquecidos em um estado fundido, injetedities em moldings: https://jsrpm.com/plastic injecting "> injectities em Moldings:

JS Company possui sua capacidade de controle de tolerância de ± 0,005mm e é capacidade de produzir estruturas automotivas complexas e eficientes.

js tem mais de 50 experiências de processamento de materiais , apoiando o apoio da forma de phening da formação de phening da formação de phening da formação de phening da formação de phening da formação de phening da formação de phening da formação de phen.com/Usololic.

3. data-v-7b79c893 = ""> borracha de silicone líquido

A borracha de silicone líquido é injetada em moldes pela injeção de moldagem e depois moldada por vulcanização de baixa temperatura.

4. span Class = "sentença" DatanslateId = "332e885a2d0a9712f3 "cd3cd30cd30slateId = 332e855e2d0a9712f3" data-len = "11" data-v-7b79c893 = ""> sobremolding

Em Data-pos = "0" Data-Len = "171" Data-V-7B79C893 = "">Multi component injection molding

combinando processos de injeção de moldagem de dois ou mais materiais, como plástico rígido e borracha macia, para integração funcional por meio de múltiplas bico ou moldagem de injeção empilhada, href = "https://jsrpm.com/industry/consumer-electronics"> é comumente usado em estruturas complexas de eletrônicos de consumo e dispositivos vestíveis inteligentes.

Qual é a diferença entre moldagem por injeção de plástico e moldagem por injeção de silicone?

A moldagem por injeção plástica é usada principalmente para a alta temperatura da escolha de produtos de plástico para a formação e é a construção de produtos plásticos em alta temperatura.

como projetar moldes estruturais complexos?

- Seleção de aço do molde: Para áreas de alta estresse, como cavidades profundas e molduras de paredes finas, resistência à resistência de alta resistência (por exemplo.

- Moldando o projeto da superfície: otimize a linha de despedida através da simulação do molde para evitar injeção desigual de moldagem ou enchimento de vôo devido a estruturas irregulares como inversões e solas laterais.

2. data-translateid="78556b6ed5a13268fb2ac70e665405f9" data-pos="3" data-len="30" data-v-7b79c893="">Optimization of pouring system

- Tecnologia do canal de fluxo de calor: adota o sistema de canal de fluxo de calor, reduza o desperdício da cabeça do material frio, melhore a uniformidade do recheio de injeção, href = "https:/jsrpm.com/injencing"> Design .

- Seleção da localização do portão: De acordo com a análise do CAE, o portão é definido em uma área de paredes grossas para evitar retenção de gás ou revasão de marcas devido ao fluxo de fusão desvios durante a injeção de molduras.

Span Style = "Font-size: 17px;"> 4. Data-translateId = "428F7145D4C10160E68F6F5A496525EF" DATA-POS = "3" Data-Len = "40" Data-V-7B79C893 = "">

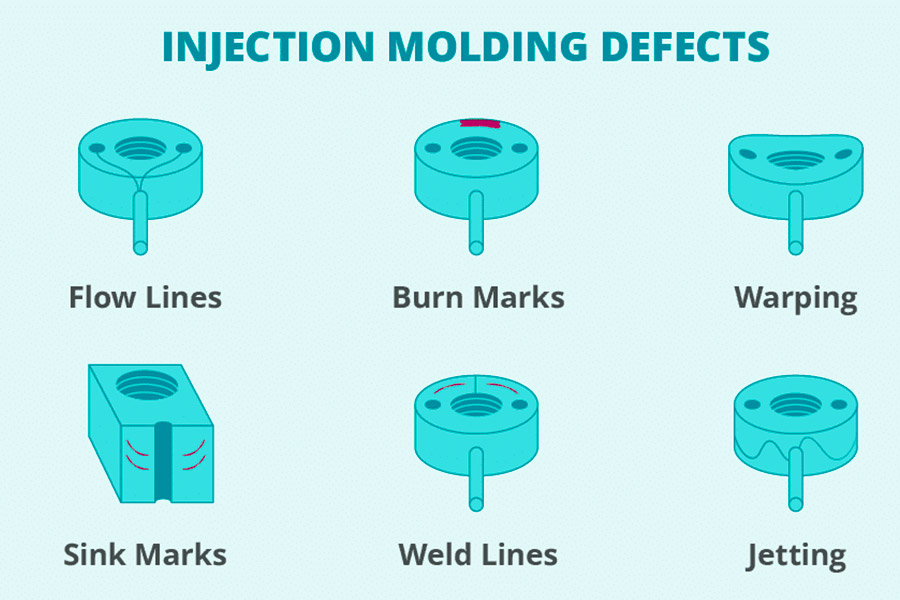

De acordo com a tecnologia de fabricação de precisão da JS Company e os requisitos de moldagem por injeção de microcomponentes, os principais equipamentos e tecnologias necessários são os seguintes: 1.I Máquina de moldagem de empurrão 2. 3.Advanced Testing Equipment Unit 4.Automated production systems 5.Special Material Processing Equipment JS company combines micro-injection molding machines, wire cutting equipment and Moldex3D simulation system to form a full-chain technology loop from molding design to precision plastic molding. Typical manufacturing case of micro parts: precision gear injection yield of 0.5mm diameter was 99.2% and dimension tolerance was controlled to ±0.003mm, demonstrating the progressiveness of the equipment system. 1.Material selection and compatibility treatment 2.Mold design and manufacture 3.Injection molding process parameter control 4.Interface integration technology Mechanical interlock design: Design of a concave or inverted structure in a die to improve bonding strength through physical interlocking. Chemical Adhesives Precoating: Special adhesives are sprayed on the surface and cured by injection molding with high temperature activation to achieve molecular level bonding (suitable for dissimilar materials). 5.Quality inspection and reprocessing In the process of injection molding, due to the influence of material properties, process parameters and equipment accuracy, the following technical problems are often encountered: 1.Material shrinkage control 2.Warp and twist 3.quality defects 4.Multi cavity mold balance 5.Risk of material degradation JS company's technological advantages Typical Case Reference Actual results: Injection-molding is the core technology of modern industry. By melting and solidifying molding plastic material, the production of simple rigid member to complex elastic member is diversified. Whether it is the efficient mass production of thermoplastic or the precise flexible molding of liquid silicone, its process adaptability covers many fields such as automobile, medical treatment and electronics. With its ±0.005mm precision mold design multi-material compatible processing, and automated production line integration integration capabilities JS Company continues to push the boundaries of precision and efficiency injection molding field, providing global customers with one-stop solutions from prototype development to mass production, enabling industry transformation and upgrading for high value added and sustainable development. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.The influence of mold temperature on the quality of injection molded parts? The mold temperature is too high, which leads to deformation of injection molding, and the surface roughness or internal stress concentration. Accurate adjustment to material characteristics (e.g. 50-80°C for ABS) are required to ensure size accuracy and appearance quality. 2.What are the commonly used types of injection molding machines? Commonly used injection molding machines types are plunger type, screw type and screw pre-formed plunger type. Among them, screw plastic has become mainstream for its efficiency and energy saving and has been widely used in the mass production of plastic products. 3.What problems can high injection pressure cause? Excessive injection pressure can lead to flash flooding (overflow), increase mold wear, and even lead to deformation or cracking of the product, as well as increased load and energy consumption of the equipment. 4.How to choose suitable injection molding materials? Consider the the product's intended use (PC strength, TPU elasticity), processing temperature and costs such as PP's high temperature resistance, TPU's flexibility, ABS's balance performance and cost. Acrylonitrile butadiene styrene

GloriaJS Prototipagem rápida e especialista em fabricação rápida Especialize -se em usinagem CNC, impressão 3D, fundição de uretano, ferramentas rápidas, moldagem por injeção, fundição de metal, chapa metal e extrusão. Marcação:

Qual equipamento é necessário para a moldagem por injeção de micro parte?

How to achieve the combination of multiple material injection molding?

What are the common difficulties in injection molding?

Technical difficulties

Industry standard solutions

JS Innovative Solutions

Material Compatibility

Compatible with ordinary plastics only.

Supports more than 50 specialty engineering plastics (such as PEI, PPS, etc.) and provides material modification services.

Formation of microstructures

The minimum feature size is 0.5mm.

Mirror etching mold technology used to achieve batch production of 0.2mm fine texture.

Complex Embedded Assembly

Manual positioning error ≥0.1mm.

Automated embedded positioning system with accuracy ±0.02mm were used.

Environmental compliance

Single material recycling.

Innovative multilayer compound structure separation technology enables efficient regeneration of PET/PC and other hybrid materials.

Fast delivery

The standard cycle is 2-4 weeks.

Digital twin technology reduces the test run time to 7 days and responds to emergency orders within 48 hours.

How can JS reduce injection molding production costs by 20%?

Summary

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.comFAQs

Resources

Blogs relacionados

Quais são as aplicações de moldagem por injeção?

Quais são os tipos de moldagem por injeção?

Quais materiais são usados na moldagem por injeção?

Como funciona a moldagem por injeção?

O que é moldagem por injeção?

Criticism

Featured Blogs