Blatt Metallblätter Verarbeitung In precision industrielle Komponenten. Schneiden, Biegeblätter Metall und Präzisionsmontage -Technologie werden häufig in Automobil-, Elektronik-, Bau- und anderen Feldern verwendet. Unabhängig davon, ob die Herstellung verzinkter Bleche oder leichter Aluminiumblechverarbeitung mit fortgeschrittener Geräte und Technologie untrennbar miteinander verbunden ist. Von der ersten Konstruktion bis zum Endprodukt sind in jedem Schritt genaue Kontrollen erforderlich, um sicherzustellen, dass das Produkt strenge Qualitätsstandards entspricht. Ob es kleine Präzisionsteile oder Large Geräte-Racks Die Verarbeitung von SCHWEISE-Metall ist eine unverzichtbare Basislinke in der modernen Branche.

Was ist Blechherstellung?

Sheet metal fabrication refers to a precision machining technique of flache Metallblätter in die gewünschte Form durch Schneiden, Beugen, Stempeln, Schweißen und andere Prozesse umwandeln. Data-Pos = "180" data-len = "218" Data-V-7b79c893 = ""> Der Kern besteht darin, Biegermaschinen, die Sterbe und andere Geräte für externe Kraft auf Metallblätter zu verwenden, adoptions Data-V-7b79c893 = ""> <"> adoptions Data-V-7b79c893 =" "> adoptions Data-V-7b79C893 =" " Prozesskontrolle, idealer Formungseffekt kann erreicht werden. Das Prozess ist in Automobilteile , mechanische Gerätegehäuse, Gebäudekomponenten usw. Es hat die Vorteile einer hohen Produktionseffizienz und niedrigen Kosten.

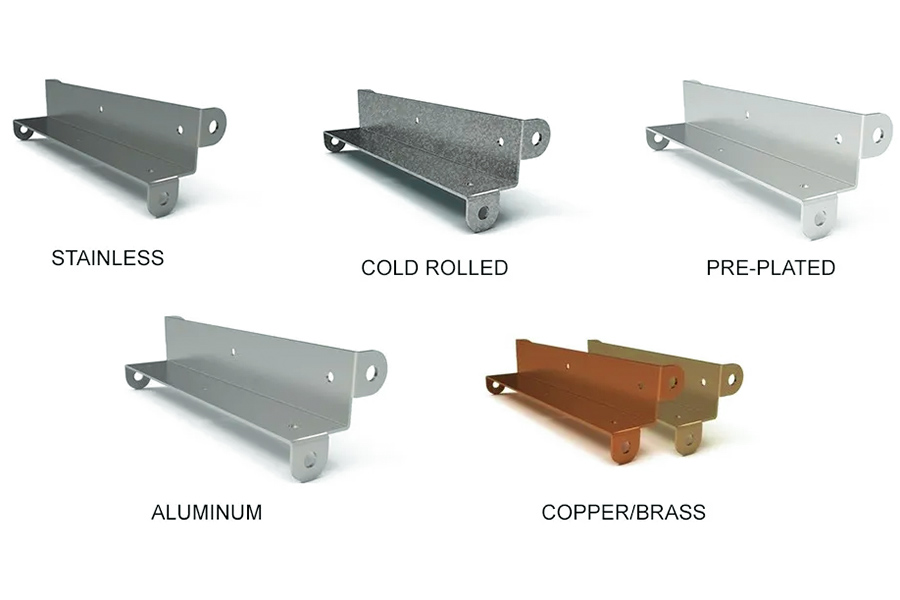

Wie wähle ich Materialien für die Herstellung von Bleche aus?

The core of sheet metal processing lies through cutting, stamping, Blechbiegung und andere Prozesse werden die Blechverarbeitung in strukturelle Teile sein, wobei die Auswahl der Materialien direkt die Leistung und die Kosten des fertigen Produkts beeinflusst. Hier sind die Main-Selektion Data-V-7b79c893 = "> Hier sind die Main-Selektion der Main-Selektion Data-V-7b79c893 ="> Hier sind die Hauptdaten-V-7b79c893 = "> Hier sind die Hauptdaten-V-7b79c893 =" ". Prinzipien:

Material characteristics and bending properties

- Stärke und Duktilität: Stahl ist hart, aber spröde und erfordert mehr Biegekraft, Aluminium ist weich und leicht zu formen (z. Flossen ).

- Oberflächenbehandlung Anpassungsfähigkeit : Galvanisierte Bleche. Kompensation.

- Blechbiegungsprozess Überlegungen: Die Materialdicke wirkt sich direkt auf die Formauswahl aus (z. B. 1m (Aluminum ".

2. data-pos = "3" data-len = "33" Data-V-7b79c893 = ""> Anwendungsszenarioanforderungen

- Leichte Anforderungen: Electronic Castings am besten aus Aluminium- und Aluminium -Magnesiumlegierung mit einem Gleichgewicht zwischen Festigkeit und Gewichtsverhältnis.

- Wetterwiderstandsanforderungen: Außengeräte (wie Laternenpfähle) sollten aus verzinktem Blatt oder Edelstahl bestehen, um Korrosion und Oxidation zu widerstehen.

- Leitfähigkeitsszenario: Kupfer ist das bevorzugte Material für die Wärme des Schaltungsscheibenscheibens, das in hohe Leitfähigkeit und Wärmeableitungen Effizienz eingeht.

- Precise control of sheet metal bend: Use a CNC bending machine preset rebound value (such as 1-2 degrees of stainless steel compensation) to ensure accuracy of Winkel.

- Mould-Plate-Übereinstimmung: Für dünne Platten (≤ 2 mm), scharfe Schneidwerkzeuge werden verwendet, um Burr zu reduzieren. Cracking.

Materialkostenvergleich: Ordinärer Kohlenstoffstahl Der niedrigste Preis, die Titanlegierung hat die höchsten Kosten und muss Leistung und Budget berücksichtigen.

Was ist der Prozess der Blecherherstellung?

Digital design and analogue

- Vollständige 3D-Modellierung mit speziellen Software wie SolidWorks/Inventor.

- Genauige technische Zeichnungen werden über AutoCAD generiert ( Support-Uploads in Formaten wie Step/iges ).

- CAE-Software, die mit Simulation der Biegeabprallkompensation von Biegung>

verwendet wird. - JS-Technologie Highlights: Mit 20 Jahren Erfahrung, Unser Engineering-Team bietet Parameteroptionsprogramme, um Versuche und Fehler zu reduzieren.

Precise selection of materials

- Konventionelles Material: SPCC/SGCC-Kaltplatte, Sus Edelstahl, Al5052 Aluminiumplatte und mehr als 50 andere.

- Spezielle Anforderungen: Kupfermaterialien, Titanlegierungen, Verbundplattenanpassung.

- JS Vorteil: 98% der Bestellungen werden in der Zeit und inventaristisch zu liefern.

- Spezielle Anforderungen: Kupfermaterialien, Titanlegierungen, Verbundplattenanpassung.

Efficient cutting and shaping

- Laser-Schneiden (Accuracy (Span) ± 0,02 mm).

- CNC-Stanzmaschine (3 mm dicke Platte).

- Wasserstrahlschneidung (für Teile mit komplexen Formen).

- JS-Technologie: selbstentwickelter verschachtelter Algorithmus verbessert die Materialnutzung um 92%.

Precision bending

- Vollautomatische Biegereinheit (3T-300T-Tonnage).

- v-Groove Adaption-System (minimal gekrümmte Kante 1.5mm).

- Echtzeitdrucküberwachungssystem (± 0,01 mm Wiederholbarkeitsgenauigkeit).

- JS Core-Technologie: Entwickeln Sie die Bend-Rückprall-Vergütungsdatenbank unabhängig von SHOCE BEGENTORANCE ± 0,005MM.

<"> <">

- Roboter MIG/TIG-Schweißarbeitstation.

- Laser-Weld-Tracking-System .

- Schweißverformungsprozess-Prozesspaket.

- JS-Merkmale: Automobile-Schweißstandard , Schweißstärke-Testpassrate von 100%.

Surface Treatment Process

- Elektrophoretische Beschichtung (Salzspray-Test ≥ 500 Stunden).

- Pulverbeschichtung (Farbanpassung). >

- Nickelbeschichtung (Dicke kann zwischen 0,0001 und 0,002 mm gesteuert werden).

- js Umgebungsmaßnahmen: 85% Wasserfarbe Nutzungsrate, 60% Reduzierung der VOC-Spannungen .

Was sind die Unterschiede in den Biegeparametern zwischen verzinktem Blatt und Aluminiumblatt?

Vergleich von Biegeparametern Unterschieden verzinkt und Aluminiumblatt

| Parameter/Materialien | verzinktes Blech | Aluminiumblech |

| Rebound-Tendenz | Kleine Abpraller (verzinkte Schicht erhöht die materielle Steifheit). | Der Rückprall ist groß (der Kompensationswert muss erhöht werden). |

| Empfohlener Biegeradius | Minimaler Radius ≥ 0,5 t (t ist Plattendicke). | Minimaler Radius ≥ 1,0T (um ein Riss zu vermeiden). |

| Temperaturempfindlichkeit | Kaltes Biegen ist stabil. | Hochtemperaturbiegung wird leicht weicher (Raumtemperaturbehandlung ist am besten). |

| Schimmelpilzrate | Der Reibungsverlust der verzinkten Schicht verkürzt die Lebensdauer des Stempels um etwa 20%. | Aluminiumsperrungen haften leicht an Formen (müssen regelmäßig gereinigt werden). |

| Biegewinkelkontrolle | Die empfohlene Rückprallkompensation beträgt 0 ° -1 °. | Der Wertentwicklungswert sollte bei 1 ° -3 ° reserviert werden. |

| Schwierigkeiten zur Behandlung von Burrs | Die Zinkschicht-Burrs sind anfällig für Ablösung. | Aluminium-Burrs müssen fein poliert werden. |

| Unterschiede in der Duktilität | Niedrige Duktilität (leicht zu brechen). | Hohe Duktilität (für komplexe Formen). |

| Behandlung der Korrosionsresistenz | Passivierung und Rost unmittelbar nach dem Biegen. | Anodierter oder sprühter Schutz ist erforderlich . |

Detailed description of key process parameters

Rebound compensation control

- verzinktes Blatt: Aufgrund des Härtungseffekts der verzinkten Platte liegt die Rückprallmenge im Allgemeinen zwischen 0,5 ° und 1,5 °, die Biegermaschine vorhaben.

- Aluminiumplatte: Aluminiumlegierung (z. B. 3003) kann bis zu 2 ° -5 ° und der Schimmelpilzwinkel durch Versuchsbiegung dynamisch eingestellt werden.

Mold gap adaptation

- verzinktes Blatt: Der empfohlene Abstand beträgt 8% -12% der Dicke des Blattes (z. B. 0,08-0,12 mm für 1-mm-Blätter).

- Aluminiumplatte: Lücken müssen auf 12% -15% erhöht werden, um Schimmelverschleiß zu vermeiden, die durch Aluminium-Chip-Adhäsion verursacht werden.

Choice of bending Richtung

- verzinktes Blatt: Biegen Sie vor Rollrichtung vor, um das Risiko eines Abblätterns der verzinkten Schicht zu verringern.

- Aluminiumblatt: Vermeiden Sie senkrecht zur Faserrichtung, um die Querschnittstärke nicht zu reduzieren.

Welche Werkzeuge sind entscheidend für die Blecherherstellung?

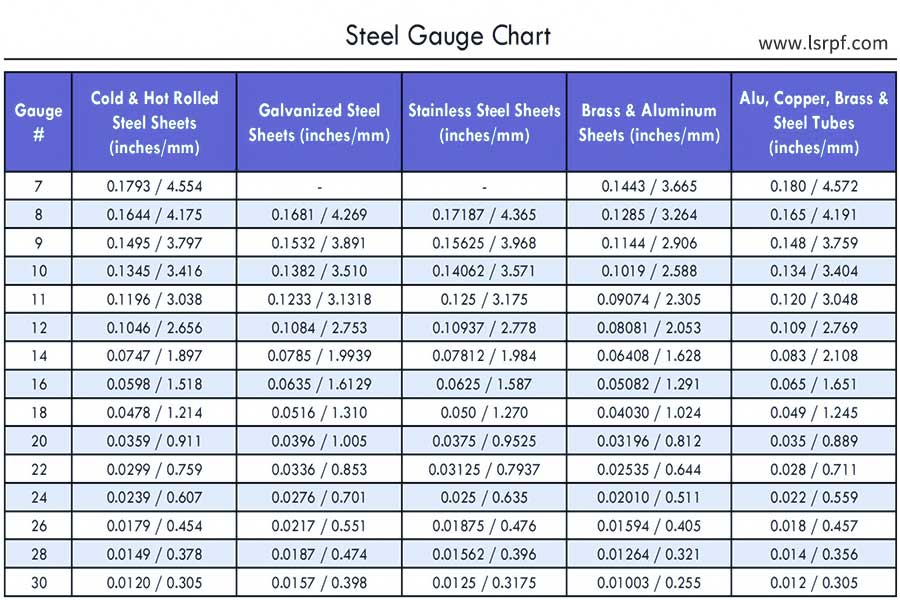

Folgende Werkzeuge und Techniken der Blechverarbeitung, Kombinieren der Leitlinie "> Kombinieren"> Kombinieren der Leitlinie "> Kombinieren der Leitung von The Guidance of the SHET MAYSEL. Diagramm:

1. Data-V-7B79C893 = ""> Schneidwerkzeuge

- Laser Cutting Machine: Suitable for thin plates (≤6mm) with accuracy ±0.02mm. See thickness chart for power and focus selection.

- CNC punch: For medium thickness plates (1-8mm), the thickness map parameters (e.g. punch spacing, plate thickness ratio, etc.) are matched through the mold library.

- Plasma/waterjet cutting: applies to thick plates (>8mm), adjusting cutting speed and air pressure through thickness chart to reduce thermal deformation.

2.Bend tools

- Bend machine: Adjust the opening angle of the V-shaped groove according to the sheet metal gauge chart (e.g. 1.5mm aluminum plate requires an opening angle of 88° for V-shaped groove).

- The gap between the lower molds should be set according to the formula (gap= thickness * coefficient) to prevent the galvanizing layer from peeling or aluminum from cracking.

- Roll bending machine: For cylindrical/curved parts, choose roller spacing and feed speed according to thickness diagram.

3.Forming mold

- Stretch molds: For deep presses (such as car coverings), mold fillet radius (≥1.5T is selected based on thickness diagram).

- Round rolling die: When rolling a sheet (≤2mm), pre-lubricating oil is needed to reduce friction coefficient.

Metal plate connection tools and techniques

MIG/TIG welding machine:

- Thin plates (≤3mm) are welded with pulses to avoid burnout (current range 50-150A).

- The thickness plate (>3mm) is welded in several layers and the temperature and weld spacing between the layers are determined in accordance with the thickness diagram.

Laser welding: Precision components,such as electronic components, require adjustment of spot diameter and focus.

2.Riveting tools

- Rivet gun: Select rivet diameter to match plate thickness.

- Hydraulic riveters: Calibration pressure values (≥8 tons for 3mm plates) are required for heavy duty plates (e.g. stainless steel).

3.Adhesive technology

- Epoxy resin adhesives: For sheet adhesives (such as electronic device casings), the thickness of the adhesive layer (0.1-0.3mm) should be controlled.

- Structural adhesive: When splicing thick plate, it must be combined with the curing schedule.

What do sheet metal fabricators do?

Core players in the industry

1.Key links in the industrial chain

- Upstream undertaking: Coordination of steel, non-ferrous metals and other raw material suppliers to ensure stable supply of plate.

- Downstream support: Precision metal components for automotive, electronics, home appliances, aerospace and other industries are fundamental to manufacturing supply chain.

2.Technology Transformation Hubs

- Translating customer requirements (e.g. CAD drawings, samples) into scalable production process solutions.

- Combine materials science and mechanical engineering knowledge to solve complex structural design and processing problems.

3.Customized solution providers

- According to the demand of different industries, the development of differentiated products and high-end, environmental protection industries, automobile covering parts, medical equipment casings, communication base station sheet metal accessories and so on have set up pilot projects.

- Provides flexible manufacturing capabilities from prototype design to mass production.

4.Standardization promoters

- Compliance with ISO, ASTM and other international standards to ensure product quality consistency.

- Promote industry process standardization (such as bending tolerance, welding specifications, etc.) to improve overall manufacturing level.

Core responsibilities of the industry

1.Quality and safety assurance

- Strict control material inspection (e.g. chemical composition inspection, mechanical performance inspection).

- Implement full process quality control (e.g. size accuracy, surface defect detection) to ensure that products meet safety standards (e.g. compressive strength, corrosion resistance).

2.Driven by technological innovation

- Advanced laser cutter and robot bending system are introduced to improve processing efficiency and accuracy.

- Development of green manufacturing processes (such as lead-free soldering and environmentally friendly surface treatment) to reduce energy consumption and pollution.

3.Cost and efficiency optimization

- Reduce cardboard waste (typically utilization rate ≥85%) through intelligent typesetting software.

- Optimize production processes (such as automatic loading and unloading, process linkage), shorten delivery cycles.

4.Responsibility for sustainable development

- Promotion of circular economy (e.g. waste recycling, waste heat recovery, etc.).

- Reduction of carbon emissions (e.g. use of EDM instead of traditional flame cutting).

How do global and local factors affect sheet metal fabrication?

1.Global drivers

- Technological innovation: Automation (robotic bending), promotion of new materials (aluminium/titanium alloy), improvement of accuracy and efficiency.

- Economic volatility: Raw material prices and tariff policies,such as the U.S.-China trade friction that has caused North American sheet metal companies to turn to local or Southeast Asian suppliers, have forced supply chain localization to localize.

- Environmental pressure: Global carbon reduction targets promote green manufacturing, such as requiring sheet metal companies in the Los Angeles area to adopt solar powered equipment and waste recycling systems. The rental for sale model, which requires manufacturers to design detachable and recyclable sheet metal components, is being promoted in the European market.

2.Key local elements

- Cost and skills: Developed countries tend to automate (Los Angeles has higher labor costs), while developing countries,such as Southeast Asia, rely on low-cost labor.

- Industry clusters: Los Angeles's automotive and aviation industry clusters driving sheet metal manufacturing toward precision and customization, such as rapid mass production of Tesla panels.

- Policy and logistics: California's strict air pollution control regulations restrict traditional welding processes and promote laser welding. As a major global hub, Port of Los Angeles has shortened the import and export cycles for raw materials and products, but also faces the risk of delivery delays caused by port congestion.

3.Industry Future Trends

Digitization and data-driven approach:

Deploy sensors to monitor device status in real time and perform predictive maintenance to reduce downtime. At the same time, machine learning algorithms are used to balance order priorities and maximize equipment utilization.

Deepening sustainable manufacturing:

- Recycled aluminum Application: Companies Los Angeles use 60% recycled aluminum to produce auto parts and receive tax incentives from the state.

- Zero waste target: Using powder metallurgy technology to produce high performance composites from waste, reducing landfill volumes by 90%.

Trends in regional division of labour:

Offshore returns: Some companies are using their Mexican plants as satellite bases in Los Angeles, utilizing the North American Free Trade Agreement to reduce tariffs while maintaining supply chain agility.

Why invest in sheet metal manufacturing for your project?

Technical advantages of professional sheet metal manufacturer

1.Ultra precision machining capability: ±0.005mm tolerances were achieved using CNC laser cutting, CNC bending, robot welding, etc. (JS case: 95% of projects achieved this accuracy, reducing rework by 90%).

2.Automation and efficiency gains: Fully automated production lines, such as 300T bender unit, shorten production cycles and regular orders are delivered within 1-2 weeks (15% shorter on average JS project cycles).

3.Material and process compatibility: Optimize metal sheet selection, balance strength and cost based on sheet metal specifications, and provide custom finish.

Commercial value of working with sheet metal manufacturers

1.Accelerate product launch

- Rapid prototyping verification (3D printing/CNC sampling) shortens the design iteration cycle and supports a seamless transition from concept to mass production.

- JS undertakes to provide an offer within 24 hours of submitting CAD documents and to prioritize production upon confirmation.

2.Cost controllability and risk avoidance

- One-stop services include design optimization, process validation and delivery to reduce communication costs in outsourced processes.

- JS uses process databases to predict risks (such as white-edged bending of galvanized sheets) and provide solutions to reduce scrap rates.

3.Quality and Compliance Assurance

- The ISO 9001 certification system ensures product consistency by providing material reports, testing certificates and traceability records.

- JS Case: Medical equipment sheet metal parts are FDA-approved, with an error rate of less than 0.02%.

Summary

Sheet metal fabrication is a complete process of machining metal sheets into high-precision functional components. The core is to control the bending angle and clearance accurately according to the thickness of the metal plate by means of numerical control bending machine and laser cutting equipment to ensure that the finished product tolerance reaches ±0.005mm.

From car panels to medical equipment casings, sheet metal processing not only supports the precision development of modern manufacturing, but also promotes sustainable development through green manufacturing. JS Precision Manufacturing and other enterprises, with ultra-high precision, 98% on-time delivery and a global supply chain, continue to provide reliable solutions across industries to help customers grasp market opportunities.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.What are the common methods of sheet metal surface treatment?

Spray, plating, anodic oxidation, passivation, wire drawing, sandblasting, chrome plating, electrophoretic coating, hot-dip galvanizing, chemical polishing.

2.How to eliminate the curved white edge of galvanized sheet?

This can be done by adjusting the bending radius, optimizing mold gap, using special lubricants or precoating with anti-oxidation coatings. Matching process parameters can effectively inhibit the shedding of zinc layer.

3.Why does sheet metal manufacturing require a gauge chart for sheet metal thickness?

It can guide the selection of plate processing parameters, guarantee the forming accuracy of different thickness sheets, avoid cracking and rebound deformation, and is the core of optimizing process efficiency and cost control.

4.How does sheet metal processing ensure environmental protection?

Green manufacturing and sustainable development using environmentally friendly materials (such as water-based paints), energy-efficient equipment, waste recycling systems, low-pollution processes (such as lead-free soldering), reduced energy consumption and waste emissions in conjunction with ISO 14001 certification standards.