Изготовление листового металла широко используется в автомобилях, электронике, аэрокосмической, домашней приборах и других полях. Легкий алюминий S Heet Metal и Коррозионное оцинкованный data-translateid = "6BF8240734682FAA902A85FBBC5E45AC" DATA-POS = "0" DATA-LEN = "116" DATA-V-7B79C893 = ""> MEET MEATLE может быть преобразован в промышленные компоненты в соответствие с требованиями к сорта с помощью листового металла data-translateid = "6BF8240734682FAA902A85FBBC5E45AC" DATA-POS = "0" DATA-LEN = "116" DATA-V-7B79C893 = ""> Изготовление . As an industry-leading company, JS is committed to Предоставление решений настройки для изгиба из листового металла от проектирования до производства, помогая предприятиям достичь двойных прорывов в эффективности и качестве.

Что такое изготовление листовых металлов?

листовой металл Изготовление -это процесс резки и изгиба металлических пластин в точные структурные детали . Он широко используется в автомобильной и электронической промышленности. изгиб листовой металл Производительность регулировки и точность сборки. способность производителей листового металла Для интеграции пластичности металлических листов в легкий, высокопрочный конечный продукт стал ключевой технологией современной промышленности.

Каковы ключевые методы для изготовления листового металла?

1.cutting

Общие методы для обработки и удаления деталей листового металла включают:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1"> Принцип

Применимые сценарии

Сильные и слабые стороны

лазерная резка

Высокая точность, сложная графика.

Это дорого и медленно.

резка

отсечение давления в плесени.

Линейная резка.

быстро, но ограничен простыми формами.

резка струй воды

Вода высокого давления, смешанная с абразивами.

Тонкий, чувствительный к теплу материал.

Нет теплового шока, но неэффективно.

2. Sheet Metal Bend

Основной процесс изменения угла пластины с помощью пластической деформации включает в себя:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000; высота: 211,859px;" border = "1"> method

Принцип

Применимые сценарии

Сильные и слабые стороны

тормоз сгибание

Применить давление на изгибную машину.

Точные углы, производимые массовые.

оборудование дорого, но точное.

изгиб воздуха

Применить локальное давление на форму.

Углы сложны.

Не требуется форм, но точность низкая.

изгиб рулона

Непрерывная пластическая деформация ролика.

Круглые трубы и изогнутые компоненты.

Подходит для длинных полос и низкой эффективности.

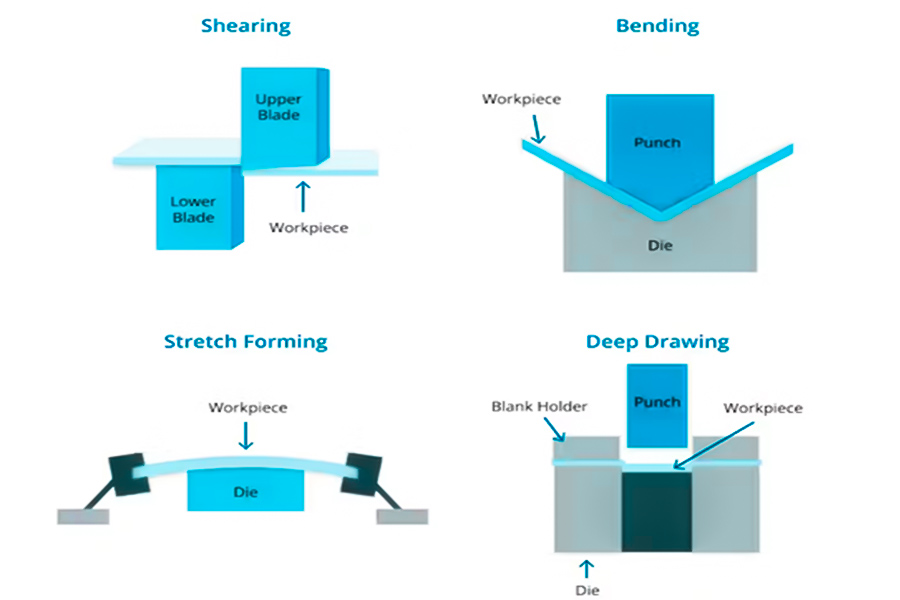

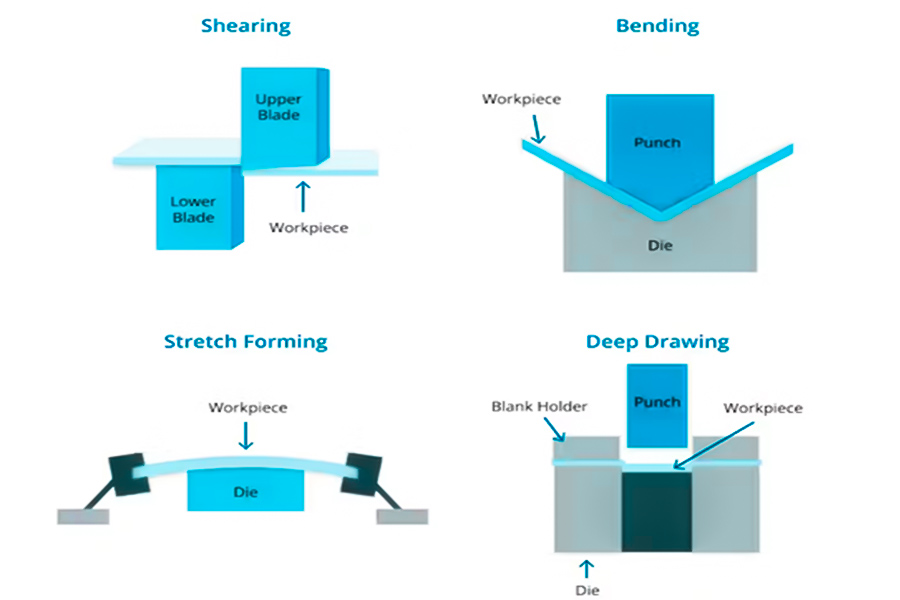

3. штамп

Использование форм для применения давления на лист, создавая такие функции, как Holes и Grooves:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1"> Принцип

Применимые сценарии

Сильные и слабые стороны

punching

Punch Horles в формах.

через отверстия и нерегулярные отверстия.

Высокая эффективность, но высокая стоимость плесени.

формирование

Пластическая деформация форм.

сложные структуры (такие как фланцы).

Подходит для больших количеств и низкой гибкости.

4.Forming

Производство комплексной геометрии посредством пластической деформации:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1"> Принцип

Применимые сценарии

Сильные и слабые стороны

глубокий рисунок

Несколько растяжений и формирования.

контейнер с глубоким полостью (например, корпус аккумулятора).

Скорость использования материала высока, но структура плесени сложна.

глади

Локализованное истончение увеличивает высоту.

Абажур и посуда.

Единообразие толщины стенки необходимо управлять.

5.connect

Объедините несколько компонентов листового металла в полную структуру:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1"> Принцип

Применимые сценарии

Сильные и слабые стороны

сварка

Подключение к таянию материала.

спрос высокой интенсивности.

Риск деформации требует специализированного оборудования.

сварка

Механическая фиксация.

Сцена должна быть разобрана.

Обратимо, но менее интенсивно.

клея

химическая связь.

Запечатывание или украшение.

Нет тепловой деформации, но плохая температурная сопротивление.

Ядро обработки листовых металлов заключается в гибком выборе резки, изгибы, штамповки и других методов в сочетании с характеристиками процесса и производственными требованиями, чтобы достичь эффективных и точных деталей.

Каковы основные типы процессов для Aluminum HEET MEATLE CANKING?

Каковы основные типы процессов для Aluminum HEET MEATLE CANKING?

1.cutting

Общие методы для обработки и удаления деталей листового металла включают:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000;" border = "1">2. Sheet Metal Bend

Основной процесс изменения угла пластины с помощью пластической деформации включает в себя:

<таблица стиля = "Пограничный коллапс: коллапс; ширина: 100%; ширина границы: 1px; пограничный цвет: #000000; высота: 211,859px;" border = "1">3. штамп

Каковы основные типы процессов для Aluminum HEET MEATLE CANKING?

Каковы основные типы процессов для Aluminum HEET MEATLE CANKING? 1. Алюминиевый листовой металл B Lanking

- Особенности: Высокопринятые и сервоприводы используются для беззащитный и вертикальный резание с допуском ± 0,02 мм.

- Технические основные моменты: необходимо управлять промежуткой между формами (0,01-0,03 мм) и использовать систему визуального позиционирования CCD для увеличения производства.

- Особенности: ОДИНАЯ ПЕРНАЯ КОРОБА, ГЛУБА> Диаметр (например, лотки аккумулятора), соотношение глубины растяжения ≤2,5.

- Сложность: алюминиевый отскок требует компенсации (коэффициент компенсации от 0,5 ° до 2 °) и Уметь Адгезия.

3. Изгиб алюминиевого листового металла

- v-образный изгиб : подходит для электрического корпуса равных правых структур, плесени Radius olius ≥1.5.5. толщина.

- изгибание катания: непрерывное прокат цилиндрических/конических частей (например, кронштейн Post Post) с минимальным радиусом изгиба r = 2t.

- Техническое ядро: Сервогинговая машина оснащена системой обратной связи в реальном времени с помощью моделирования CAE.

- Принцип: давление переноса жидкой среды, уменьшение износа плесени, подходит для сложной структуры вурой . .

- Корпус: аккумуляторный аккумулятор новой энергии, ошибка универсации толщины стенки ≤0,1 мм.

- Требования к оборудованию: мониторинг флуктуаций давления в режиме реального времени (точность ± 0,5 МПа), чтобы предотвратить перегружение алюминиевых пластин.

Листовый металл: Основные преимущества

адаптивность алюминия

Типичные приложения

b lanking

Высокое качество поперечного сечения, подходящее для тонкой пластины.

0,1-2,0 мм алюминий SHISE MEATLE.

Precision Electronics.

После формирования скорость использования материала высока.

0,5-4,0 мм пластичный алюминиевый материал.

батарея.

изгиб

Настраиваемая кривиза и гибкое производство.

толщина всего алюминия листовой металл .

кронштейн, изогнутая оболочка.

Гидроформирование

Сложная полая структура с равномерной толщиной стенки.

Высокий алюминиевый сплав 6-серии.

Новые энергетические автоматические компоненты.

- Материал: Стоимость к продукту может быть выбором 1 серия (чистая алюмана), 5-й серия. Алюминий Листовый металл .

- Управление восстановлением: Упругая деформация алюминиевых материалов смещена с помощью конструкции компенсации плесени (например, увеличение угла пребенда).

- Обработка поверхности: анодированная (твердость HV ≥150) или пассивирование для улучшения коррозионного сопротивления.

Какой процесс сварки подходит для Galvanified HEET MEATLE ?

Циновое покрытие на Galvanized Steel Металл является изменчивым, , а традиционная диска MIG может легко создавать Stomata. PULSE MIGERENCESESESTERESE и PULSE PULSE MIGECESE и PULSE PULSE и "PULSE PULSE OF-7B79C893 ="> ">" испарение в пул расплава, контролируя токуную форму волны при сохранении прочности сварки.

JS принимает усовершенствованное оборудование MIG, поддерживает режим импульса, принимает профессиональные сварки (содержащие кремниевые и алюминиевые), эффективно подавляет веж

2. Лазерная сварка Лазерный луч с высокой плотностью энергии может быстро растопить металл, уменьшить зону теплового эффекта и избегать крупномасштабного окисления слоя цинка. подходит для сварки точной оцинкованной стали METAL Компоненты , такие как автомобильные детали. JS принимает лазерную сварку с высоким уровнем точного Требование допуска ± 0,005 мм. 3.

подходит для тонкой оцинкованной стали Metal (например, 0,5-3 мм), металл расплавляется in situ через мгновенное действие давления и тока электрода, и слой цинка сжимается под давлением, чтобы сформировать надежное соединение.

p> p> p> p> p> p> p> p>JS автоматизированное сопротивление. Эффективное массовое производство оцинкованной стали Металл

дополнительные преимущества для компании JS

- Pre-treatment and post-treatment: Provides surface cleaning (e.g. chemical zinc removal) and post-welding coating services for galvanized steel metal to improve corrosion resistance and extend the service life of components.

- Material diversification: More than 50 metal materials, including galvanized steel metal, are processed, supporting customization from prototype to mass production.

- Environmental process: Reduce zinc vapor emissions using low-pollution welding technology and exhaust gas recovery systems, in line with the 20% reduction target set by JS.

Каково влияние форм изгиба на точность излучения?

The influence of bending mold on the machining accuracy of bend sheet metal is mainly reflected in the following aspects:

1.Design of mold fillet radius

- Impact angle accuracy: If mold fillet radius is too small, it will produce cracks in the plate at the crease. If the radius is too large, the theoretical bending angle may change (for example, the actual bending angle of a 90° mould may become 88 °-89 °).

- Rebound compensation: The mold needs to design a pre-bending angle (e.g. add 2-3° to compensate for rebound of aluminum plates) based on the ductility of the material.

2.Matching mold gaps

- Too small gap: Causing too much friction between the plate and mold, causing scratches or surface indentations, affecting the appearance quality.

- Excessive clearance: Results in plate sliding bias, resulting in bending angle deviation (error up to ± 1°-2°).

3.Mold surface roughness

- High precision mold: Surface roughness Ra≤ 0.8μm, can reduce plate scratching and improve surface smoothness.

- Rough: When Ra> 1.6μm, it is easy to cause metal debris to adhere to the surface of the plate, affecting subsequent spraying or welding processes.

4.Mold materials and heat treatment

- Mold hardness: Cr12MoV mold steel (HRC58-62) has a service life more than three times that of normal 45# mold steel and is not easily deformed after long use.

- Heat treatment defects: Mold quenching inhomogeneity will accelerate local wear and affect bending consistency.

5.Mould wear and maintenance

- Wear threshold: When the mold blade wears more than 0.1mm, the stability of the bending angle decreases significantly (e.g. from ±0.5° to ±2°).

- Maintenance cycle: It is recommended that mold size be checked every 5,000 processing cycles and repair or replaced in a timely manner.

6.Match of mold thickness and plate thickness

- Thin plate mold (≤ 1mm): Alloy inserts are required to prevent breakage of the mold due to excessive punching force.

- Thick plate mold ≥ 3mm: It is necessary to add a gasket design to the bottom of the mold to disperse pressure and avoid plate layering.

Как выбрать толщину материала листового металла?

The selection of sheet metal part material thickness requires comprehensive consideration of function requirements, process limitations and economy. Sheet metal gauge chart is the core tool to guide selection. Here are the key steps and highlights:

1.Clarify application scenarios and load requirements

- Static loads (such as brackets and shells): The yield strength of a sheet metal gauge chart, select the minimum thickness that can withstand the expected load.

- Dynamic load (e.g. car chassis): Fatigue strength needs to be calculated, usually 20% to 30% more than static load.

- For example, if the electrical casing is subjected to a concentrated load of 50kg, according to the gauge chart, SPC steel 1.5mm thick meets the bending strength requirements.

2.Matching thickness range of manufacturing process

Process type

Applicable gauge range

Process limitations

Laser cutting

0.1mm-20mm

The cutting speed of thick plate is reduced and the risk of thermal deformation is great.

Bending

0.5mm-6mm

The angle of the V-mold needs to be adjusted to the thickness (e.g. using the 80° V-mold to make a 6mm plate).

Deep stamping

0.6mm-3mm

The material elongation rate should be ≥20% (such as aluminum alloy 5052).

The sheet metal gauge chart will indicate the recommended thickness range for different processes, such as 0.8mm-3mm for aluminum sheet metal (1060) bending.

3.Balance cost and material utilization

- Thin plates (≤1mm): Low cost but easily deformed, suitable for large quantity of load bearing components (e.g. computer chassis).

- Thick plates (≥4mm): Material costs and processing difficulty are high and require optimal selection through gauge chart (e.g. replacement of 4mm plates with 3mm plates and reinforcement).

- Economic Thickness: Refer to industry-standard sheet metal specifications, such as the commonly used 1.0mm-1.5mm galvanized sheet metal in the automotive industry, to balance strength and cost.

4.Consider the impact of connectivity technology

- Welding: When plate thickness difference is more than 30%, step welding or groove treatment is required (e.g. cross-welding between 2mm and 1.5mm plates).

- Riveting: The total thickness of the plate ≤3 times the riveting diameter (e.g. M5 riveting for aluminum plates ≤1.5mm in thickness).

Sheet metal gauge chart application

Тип материала

Gauge number

Actual thickness (mm)

Typical use

SPCC cold rolled steel

18

1.2

Electrical enclosures and shelves.

AL1100 aluminum sheet metal

20

0.9

Heat sink, electronic device casing.

SUS304 stainless steel

16

1.0

Medical equipment, food equipment.

Каковы причины выбора изготовления листового металла JS?

1.Production accuracy and quality control

JS uses imported laser cutting equipment with accuracy of ±0.005mm, far exceeding industry standards (traditional sheet metal fabricators is typically ±0.02mm), especially for precision electronics (such as cell phone heat sinks) and aerospace components, and solves the deformation problem of high-strength steel and aluminum alloys.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Cutting accuracy

±0.005mm (laser cutting)

±0.02mm-0.05mm (traditional CNC stamping machine)

Rebound compensation accuracy

AI algorithm compensation, error ±0.01mm.

Manual adjustment, error> 0.1mm.

Surface quality

Thermal effect zone<0.1mm, no burrs.

The burrs were obvious and needed polishing.

2.Speed of delivery and productivity

JS standardized orders can be delivered within 1-2 weeks and urgent orders can be returned within 24 hours, with a 30% reduction in wait times. Multi process collaboration (cutting+bending+welding) is achieved synchronously, increasing overall efficiency by 30% -50%.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Standard delivery times

1-2 weeks.

3-4 weeks.

Small batch response

24-hour express delivery.

Mold replacement takes 1-2 hours and is only suitable for mass replacement.

Process collaboration

Multi process parallel processing.

A single process is produced in stages.

3.Material selection and cost optimization

There are more than 50 kinds of metallic and non-metallic materials in JS, and the material utilization rate is over 92%.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Number of material warehouse

More than 50 varieties (including special boards).

10-20 types(conventional metals only).

Material utilization rate

92% + (remaining material intelligently matched).

80-85% (depending on fixed-specification procurement).

Cost control

Recycling excess materials can reduce costs by 15%.

Material waste is widespread and systematic optimization is lacking.

4.Technological innovation and process upgrading

JS introduces artificial intelligence vision correction system and self-bending devices to support complex surface shaping and provide integrated solutions.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Technical Capability

AI corrects + automatically bends.

Manual adjustment is the main focus.

Process innovation

Support irregular parts/surfaces.

For flat/simple bending only.

Simulation verification

Built-in CAE simulation system.

No simulation capability, by trial and error.

5.Global service capability

JS supports multilingual drawings and global logistics tracking (DHL/UPS dedicated line) and serves clients in more than 30 countries.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Scope of services

Global delivery (more than 30 countries).

Local or regional markets only.

Communications support

Multilingual drawing and technical team.

English documents rely on third-party translation.

Delivery times

International orders take 4 to 6 weeks.

Subcontracting causes delays to third parties.

In the field of industrial manufacturing, sheet metal fabrication has become an indispensable technical pillar in modern industrial system due to its diverse process and extensive application scenarios. Sheet metal processing involves cutting, sheet metal bend, stamping, welding and other core processes, sheet metal sheets into a functional and aesthetic combination of structural components. Whatever the material, the perfect balance can be achieved through process optimization and material selection.

JS Precision Manufacturing has 20 years of industry experience and an intelligent production system that pushes traditional sheet metal processing to a new level. It redefines the technical boundaries and value standards of sheet metal processing by providing global customers with one-stop solutions ranging from prototype design to mass production with extreme precision, adequate material adaptability and green manufacturing concepts.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

1.What is the general accuracy of sheet metal processing?

Laser cutting up to ±0.005mm, CNC bending up to ±0.02mm, traditional stamping up to ±0.1mm. High-end equipment combined with AI algorithms can break through micron level accuracy and meet high-demand scenarios such as precision electronics and aerospace.

2.What's the difference between laser cutting and traditional stamping?

High precision Laser cutting (±0.02mm), no mold required, suitable for irregular holes. Punching depends on die, low cost, suitable for large-scale wire cutting.

3.Why does the automotive industry heavily use sheet metal fabrication?

With its lightweight, high strength and high efficiency, the automobile industry relies on sheet metal processing to quickly form complex components such as bodywork and chassis, while taking into account cost control and large-scale production needs.

4.Why is sheet metal fabrication considered green manufacturing?

Sheet metal processing reduces pollution and waste by increasing material utilization (waste), low energy consumption and environmental protection меры. Realize resource recycling and cleaner production in conjunction with ISO 14001 certification.

Ресурсы

Digital modeling and fabrication

The selection of sheet metal part material thickness requires comprehensive consideration of function requirements, process limitations and economy. Sheet metal gauge chart is the core tool to guide selection. Here are the key steps and highlights:

1.Clarify application scenarios and load requirements

- Static loads (such as brackets and shells): The yield strength of a sheet metal gauge chart, select the minimum thickness that can withstand the expected load.

- Dynamic load (e.g. car chassis): Fatigue strength needs to be calculated, usually 20% to 30% more than static load.

- For example, if the electrical casing is subjected to a concentrated load of 50kg, according to the gauge chart, SPC steel 1.5mm thick meets the bending strength requirements.

2.Matching thickness range of manufacturing process

| Process type | Applicable gauge range | Process limitations |

| Laser cutting | 0.1mm-20mm | The cutting speed of thick plate is reduced and the risk of thermal deformation is great. |

| Bending | 0.5mm-6mm | The angle of the V-mold needs to be adjusted to the thickness (e.g. using the 80° V-mold to make a 6mm plate). |

| Deep stamping | 0.6mm-3mm | The material elongation rate should be ≥20% (such as aluminum alloy 5052). |

The sheet metal gauge chart will indicate the recommended thickness range for different processes, such as 0.8mm-3mm for aluminum sheet metal (1060) bending.

3.Balance cost and material utilization

- Thin plates (≤1mm): Low cost but easily deformed, suitable for large quantity of load bearing components (e.g. computer chassis).

- Thick plates (≥4mm): Material costs and processing difficulty are high and require optimal selection through gauge chart (e.g. replacement of 4mm plates with 3mm plates and reinforcement).

- Economic Thickness: Refer to industry-standard sheet metal specifications, such as the commonly used 1.0mm-1.5mm galvanized sheet metal in the automotive industry, to balance strength and cost.

4.Consider the impact of connectivity technology

- Welding: When plate thickness difference is more than 30%, step welding or groove treatment is required (e.g. cross-welding between 2mm and 1.5mm plates).

- Riveting: The total thickness of the plate ≤3 times the riveting diameter (e.g. M5 riveting for aluminum plates ≤1.5mm in thickness).

Sheet metal gauge chart application

| Тип материала | Gauge number | Actual thickness (mm) | Typical use |

| SPCC cold rolled steel | 18 | 1.2 | Electrical enclosures and shelves. |

| AL1100 aluminum sheet metal | 20 | 0.9 | Heat sink, electronic device casing. |

| SUS304 stainless steel | 16 | 1.0 | Medical equipment, food equipment. |

Каковы причины выбора изготовления листового металла JS?

1.Production accuracy and quality control

JS uses imported laser cutting equipment with accuracy of ±0.005mm, far exceeding industry standards (traditional sheet metal fabricators is typically ±0.02mm), especially for precision electronics (such as cell phone heat sinks) and aerospace components, and solves the deformation problem of high-strength steel and aluminum alloys.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Cutting accuracy

±0.005mm (laser cutting)

±0.02mm-0.05mm (traditional CNC stamping machine)

Rebound compensation accuracy

AI algorithm compensation, error ±0.01mm.

Manual adjustment, error> 0.1mm.

Surface quality

Thermal effect zone<0.1mm, no burrs.

The burrs were obvious and needed polishing.

2.Speed of delivery and productivity

JS standardized orders can be delivered within 1-2 weeks and urgent orders can be returned within 24 hours, with a 30% reduction in wait times. Multi process collaboration (cutting+bending+welding) is achieved synchronously, increasing overall efficiency by 30% -50%.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Standard delivery times

1-2 weeks.

3-4 weeks.

Small batch response

24-hour express delivery.

Mold replacement takes 1-2 hours and is only suitable for mass replacement.

Process collaboration

Multi process parallel processing.

A single process is produced in stages.

3.Material selection and cost optimization

There are more than 50 kinds of metallic and non-metallic materials in JS, and the material utilization rate is over 92%.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Number of material warehouse

More than 50 varieties (including special boards).

10-20 types(conventional metals only).

Material utilization rate

92% + (remaining material intelligently matched).

80-85% (depending on fixed-specification procurement).

Cost control

Recycling excess materials can reduce costs by 15%.

Material waste is widespread and systematic optimization is lacking.

4.Technological innovation and process upgrading

JS introduces artificial intelligence vision correction system and self-bending devices to support complex surface shaping and provide integrated solutions.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Technical Capability

AI corrects + automatically bends.

Manual adjustment is the main focus.

Process innovation

Support irregular parts/surfaces.

For flat/simple bending only.

Simulation verification

Built-in CAE simulation system.

No simulation capability, by trial and error.

5.Global service capability

JS supports multilingual drawings and global logistics tracking (DHL/UPS dedicated line) and serves clients in more than 30 countries.

Comparison items

JS sheet metal fabrication

Other sheet metal fabricators

Scope of services

Global delivery (more than 30 countries).

Local or regional markets only.

Communications support

Multilingual drawing and technical team.

English documents rely on third-party translation.

Delivery times

International orders take 4 to 6 weeks.

Subcontracting causes delays to third parties.

In the field of industrial manufacturing, sheet metal fabrication has become an indispensable technical pillar in modern industrial system due to its diverse process and extensive application scenarios. Sheet metal processing involves cutting, sheet metal bend, stamping, welding and other core processes, sheet metal sheets into a functional and aesthetic combination of structural components. Whatever the material, the perfect balance can be achieved through process optimization and material selection.

JS Precision Manufacturing has 20 years of industry experience and an intelligent production system that pushes traditional sheet metal processing to a new level. It redefines the technical boundaries and value standards of sheet metal processing by providing global customers with one-stop solutions ranging from prototype design to mass production with extreme precision, adequate material adaptability and green manufacturing concepts.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

1.What is the general accuracy of sheet metal processing?

Laser cutting up to ±0.005mm, CNC bending up to ±0.02mm, traditional stamping up to ±0.1mm. High-end equipment combined with AI algorithms can break through micron level accuracy and meet high-demand scenarios such as precision electronics and aerospace.

2.What's the difference between laser cutting and traditional stamping?

High precision Laser cutting (±0.02mm), no mold required, suitable for irregular holes. Punching depends on die, low cost, suitable for large-scale wire cutting.

3.Why does the automotive industry heavily use sheet metal fabrication?

With its lightweight, high strength and high efficiency, the automobile industry relies on sheet metal processing to quickly form complex components such as bodywork and chassis, while taking into account cost control and large-scale production needs.

4.Why is sheet metal fabrication considered green manufacturing?

Sheet metal processing reduces pollution and waste by increasing material utilization (waste), low energy consumption and environmental protection меры. Realize resource recycling and cleaner production in conjunction with ISO 14001 certification.

Ресурсы

Digital modeling and fabrication

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com