Sheet metal fabrication is a process that uses manually operated equipment to cut, bend and weld metal sheets. Workers can use soft metals to make decorations or hard metals to produce building brackets, and these finished products are widely used in the industrial field. Aluminum sheet metal is one of the commonly used materials. It is corrosion-resistant and easy to process, while galvanized steel metal has an anti-rust coating on the surface.

The entire production process includes three main links: drawing design, mold stamping, and welding assembly. Workers use precise measurements to ensure that each component meets the standard size. This technology can produce large components such as truck chassis, as well as precision parts such as mobile phone metal casings.

What is Sheet Metal Fabrication?

We employ various processing methods to shape and cut metal sheets to fit into specified sizes, and the entire process involves four major steps, molding, cutting, bending sheet metal, and assembly. In real application, we have found that the accuracy of the bending process will directly affect the assembly effect and the service life of the parts.

We can process various types of metal sheets with 0.5mm to 6mm thicknesses based on the needs of various scenes. This kind of flexibility can meet the needs of most industrial sectors for precision structural components.

What are the core processes of sheet metal fabrication?

1.Requirement confirmation stage

We will first confirm the core requirements with the client. For example, last week there was an electronic device casing project where the customer specifically requested the use of 1.2mm thick aluminum sheet metal and required 8 right angle sheet metal bending. We used 3D modeling software to draw a structural model with positioning holes and reinforcing ribs.

2.Drawing conversion process

After the modeling is completed, we will use professional drafting software to draw production drawings. The recently completed medical instrument casing project has 6 laser cutting positioning points and surface sandblasting requirements indicated in the drawings.

3.Production feasibility check

Our engineers will cross check the drawings twice. Last month, there was an industrial control box project that reduced 4 parts and saved 15% of material costs through optimized design. At the same time, key parameters will be calculated, such as the ventilation bracket needing to withstand a continuous pressure of 30kg.

4.Prototype production process

The workshop uses laser cutting equipment with an accuracy of ±0.1mm. Last week, when making communication base station components, we first used laser cutting to cut out the base plate, then completed 6 bending processes with a hydraulic bending machine, and finally assembled it with a spot welding machine. The entire process is controlled within 48 hours.

5.Actual testing and verification process

Last year, we conducted 100 loading and unloading tests and load-bearing tests on the shelf connectors made for logistics companies. According to the actual test results, the support structure was adjusted, and the load-bearing capacity was ultimately increased from 200kg to 350kg.

6.Batch production preparation

Products that pass the test will be transferred to the mass production process. At present, we adopt a modular production mode, with a daily production capacity of up to 1,500 pieces for conventional sheet metal parts and a stable production capacity of 300 pieces/day for special customized parts.

How to design sheet metal parts?

1.Key points of hole design

When designing holes, we need to pay special attention to the size and position relationship. It is recommended that the diameter of the hole be consistent with the thickness of the material itself, such as using a 2mm plate to open a 2mm diameter hole. The spacing between adjacent holes should be at least six times the thickness of the material.

It is also important to note that the holes should not be too close to the edge. We recommend keeping a safe distance of at least three times the thickness of the material.

2.Thickness control principle

We have found that maintaining uniform wall thickness is crucial to product quality. If different thickness structures must be used in the design, it is recommended to plan the stacking order and processing route of the plates in advance. According to our experience, structural parts with a thickness difference of more than 20% need to pay special attention to the positioning problem during processing, which can easily lead to dimensional deviation of the finished product.

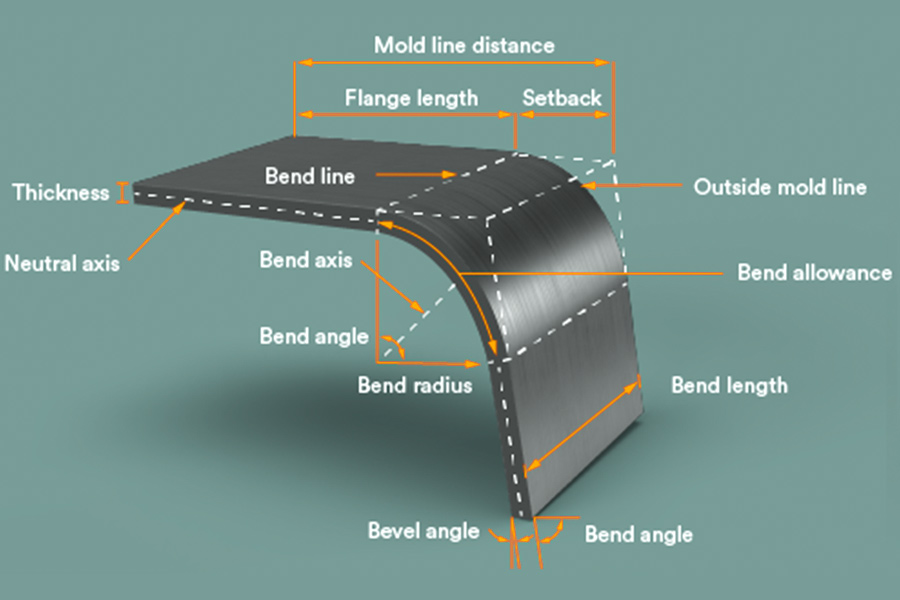

3.Sheet metal bend radius specification

In the bending process, we always adhere to the basic principle of "radius equals thickness". For example, when processing a 1.5mm thick plate, the arc radius at the bend should also be kept at 1.5mm. This simple correspondence can effectively avoid problems such as crease cracking or surface deformation. When encountering special shapes that require radius adjustment, it is recommended that you conduct sample testing in advance.

4.Allowance calculation method

When drawing a plane expansion diagram, it is best to add a section of reserved material based on the actual size. This additional material is called bending allowance. The elastic characteristics of the material need to be considered in the specific calculation, and the trial and error method is usually used to determine the best value. For conventional steel, we are accustomed to deducting 1.5 times the material thickness from the flange length as compensation. This empirical value can better balance dimensional accuracy and processing efficiency.

What types of sheet metal fabrication are there?

1.Cutting process

Cutting is the first step in sheet metal processing. Workers use shears or laser cutters to cut sheet metal into specific shapes. Shearing includes three basic operations: cutting materials, punching holes, and separating parts. For industrial orders with high precision requirements, companies prefer non-contact cutting technology. When processing 2mm thick stainless steel plates, the incision width of laser cutting can be controlled within 0.15mm.

Laser cutting technology is currently the most widely used. The process can achieve a processing accuracy of ±0.1mm, which is more than 50% more efficient than traditional shearing. Laser cutting can not only reduce material waste, but also shorten delivery cycles, and is particularly suitable for mass production of precision parts.

2.Welding process

Welding connects metals by heating or pressurizing. Common welding methods include:

MIG/MAG welding: This is the most commonly used method for connecting steel parts. Through continuous wire feeding and argon protection, the strength of a single weld can reach 90% of the parent material. When processing shelves last year, we used this method to complete 80% of the welding work.

TIG welding: When processing stainless steel water tanks, we prefer this more controllable method. During operation, the tungsten electrode must be kept 3-5mm away from the workpiece, and the heat input must be precisely controlled by the foot pedal.

Laser welding: Focusing the laser beam generates high temperature to achieve rapid welding. The heat-affected zone is small, suitable for welding precision electronic components.

3.Bending and forming

The bend sheet metal process changes the shape of the sheet through external force. During operation, the worker deforms the metal sheet along a linear axis to form a specific angle. Common equipment includes:

V-type bending machine: basic bending with a triangular mold.

U-type forming machine: making tubular or box structures.

Rolling equipment: processing arc-shaped parts.

Material thickness directly affects the bending effect. The bending radius of a 0.5mm thin plate is usually 1 times the thickness of the plate, while a 5mm thick plate requires a radius of more than 3 times. The operator needs to adjust the mold parameters according to the material characteristics.

4.Stamping process

The stamping machine cooperates with the mold to achieve rapid prototyping. This process completes cutting and shaping at room temperature at the same time, and can process 600-800 parts per hour. Basic processes include:

Punching: making mounting holes or heat dissipation holes.

Blanking: separating the shape of parts.

Drawing: forming cup-shaped parts.

Embossed: making surface textures.

Simple punching and blanking are suitable for early processing, and complex drawing processes can directly form the final product. Parts such as car doors and chassis shells are all formed by multi-process stamping.

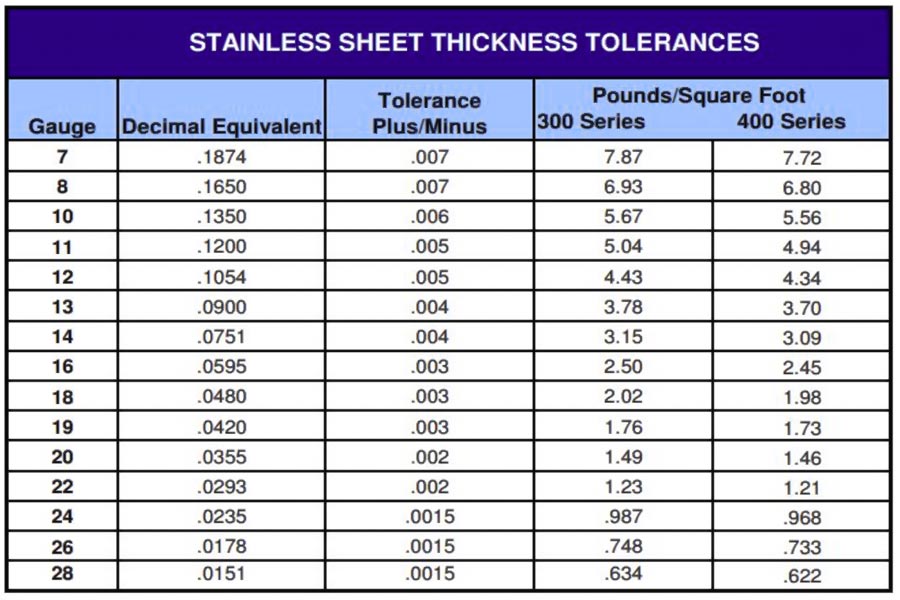

How to balance strength and cost through a sheet metal gauge chart?

In sheet metal fabrication, the key to balance strength and cost through sheet metal gauge chart is scientific selection and process optimization:

1.Understand the relationship between sheet thickness and performance

The thickness of the sheet corresponds to the actual thickness (mm/inch) corresponding to the United States Standard No. (gauge), for example:

- 16 Gauge →≈ 1.588mm (high strength, suitable for load-bearing structures).

- 22 Gauge →≈ 0.711mm (lightweight, suitable for load bearing shells).

- JS company Technology: Thickness should be selected according to material type (e.g. stainless steel 304/316, aluminium 6061). For example, during bending, thin plates (<0.5mm) are prone to cracking and need to be compensated by prepressing or adjusting the bending radius.

2.Cost optimization strategy

Precisely control the amount of materials:

During the design stage, we will use FEA software to analyze the stress conditions and find out where the thickness can be reduced. Last year, when we helped a washing machine factory design a stainless steel inner barrel, we found through simulation that the side wall was less stressed. Finally, the thickness was reduced to 1.0 mm, and the material was replaced with cold-rolled steel plate, which reduced the overall cost by 25%. In actual operation, special attention should be paid to the fact that the thinning area cannot affect the strength of the assembly holes.

Flexible selection of alternative materials:

For non-load-bearing structural parts, it is recommended to use aluminum alloy instead of stainless steel. For example, after the shell of the control box was changed to 6063 aluminum alloy, the weight was reduced by 30% and the material cost was saved by 20%. The surface treatment uses anodizing, which is both rust-proof and beautiful. A batch of outdoor equipment shells processed last year have not been rusted so far. But it should be noted that aluminum alloy bending requires a larger arc radius, which needs to be confirmed in advance.

3.Structural design optimization

Thin plate reinforcement solution:

Designers can make raised reinforcing ribs on the surface of thin plates (such as 1.0 mm). This method can increase the bending resistance of the plate to three times the original by changing the material distribution. This data is the actual test result of JS laboratory.

Combined structure application:

When the strength of a single layer of plate is insufficient, multiple thin plates can be combined by welding or riveting. For example, using three 1 mm plates instead of 3 mm thick plates can reduce the weight by 10%-15% while maintaining similar load-bearing capacity.

Bending process points:

JS company has found through mass production verification that the arc radius of the bending mold must be at least equal to the material thickness. For the common 2 mm aluminum plate, a mold with a radius of 2 mm must be used. There are two advantages to doing this. First, the angle of the part is more accurate after forming, and the rebound amount is reduced by more than 30%. Second, the mold loss is reduced, and the average service life is extended by 50 processing batches.

It should be noted that if a small radius mold is forcibly used to process thick plates, it will not only cause cracks on the surface of the parts, but also accelerate the wear of the mold. There have been failed cases of processing 2 mm plates with R1.5 molds on the production line, which eventually caused the entire batch of parts to be scrapped.

What factors should be considered when choosing suitable sheet metal fabricators?

1.Technical and process capabilities: Ensure mastery of required processing techniques (e.g. laser cutting, CNC bending, welding, surface treatment, etc.) and meet accuracy and complexity requirements.

2.Equipment and material quality: Check the sophistication of equipment (e.g. CNC bending machine, automated production line, etc.) and reliability of material sources (e.g. plate thickness tolerance, surface treatment standards, etc.).

3.Quality certification and standards: Confirmation of ISO, IATF certification and compliance with industry standards (e.g. special standards in the automotive and aviation fields).

4.Production size and delivery time: Assess production capacity to meet order quantity and ensure timely delivery, especially for emergency projects requiring flexible response capabilities.

5.Cost transparency: Compare offers to avoid hidden costs by including the full process costs (e.g. design, processing and reprocessing).

6.After-sales service and support: Understand technical support response speed, warranty policy and problem solving ability.

7.Environmental protection and safety compliance: Priority should be given to production enterprises that are waste recycling, comply with emission standards and comply with safe production standards.

8.Industry reputation and case studies: Reference past customer evaluations and success stories to verify actual delivery capabilities and technical stability.

When choosing a sheet metal fabricators, a comprehensive evaluation of its technical ability, quality control, industry experience and cost-effectiveness is required. As an industry-leading sheet metal processing service service provider advanced equipment, digital process optimization process optimization green manufacturing concept, JS Company provides high precision aluminum and galvanized sheet metal processing services to more than 2000 customers worldwide.

Summary

Sheet metal processing is a basic technology for industrial production and plays a key role in equipment manufacturing and product development. Our company has accumulated a lot of experience, in the field of aluminum sheet processing and steel sheet forming by integrating full-process services, from bending sheet metal to laser cutting systems. The average service life of products is increased by more than 15% compared with traditional processes. These new technologies make sheet metal parts lighter, thinner and more durable, ensuring stable and reliable product quality.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.Can sheet metal processing manufacture parts with complex structures?

Using laser cutting and CNC bending technology to manufacture complex structural parts, its high-precision cutting and multi-angle bending ability can be combined with welding technology to achieve complex geometry from small gap to large size.

2.Will thicker boards be stronger?

Increasing the thickness of the plate can improve the compressive and bending strength of the plate, but the plate is too thick (such as >10mm) and requires special processing (e.g. hot forming or hydraulic press) due to its stiffness, which makes it difficult to bend and prone to cracking.

3.Is aluminum alloy suitable for casting or sheet metal fabrication?

Both are acceptable. Casting is suitable for complex internal structure and mass production, with low cost and precision. Sheet metal processing is suitable for high precision curved surface or small batch customization, through laser cutting and bending to achieve lightweight and high strength.

4.How environmentally friendly is sheet metal processing?

Sheet metal processing can greatly reduce energy consumption and pollution through waste recycling (over 90% metal utilization), environmental protection processes (such as water-based spraying, powder metallurgy), and energy-efficient equipment 50% energy savings fromfiber laser cutting).