現代の製造では、シートメタル製造基本的および主要なテクノロジーとして。 href = "https://jsrpm.com/industry/industry-equipment">精密機器の製造およびその他のフィールド。 cutting 、スタンピング、曲げなど、元の金属プレートは複雑な形状のメンバーに形成されます。

多くの金属材料で、その軽量、高強度、腐食抵抗、特に by 新しいエネルギー href = "https://jsrpm.com/industry/consumer-electronics">電子製品。一方、亜鉛めっき板金は、錆耐性の表面コーティングのため、建築材料、電化製品、屋外施設に好ましい材料になりました。革新的な軽量設計または産業シナリオを追求する場合、これら2つの材料の技術的およびパフォーマンスの利点は、製造のアップグレードと開発を促進しています。

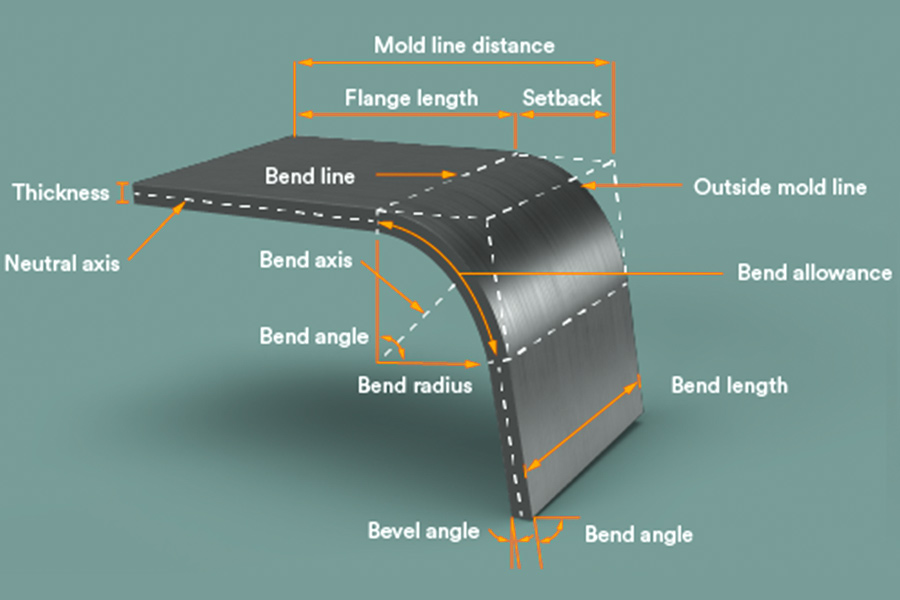

板金製造は、シートメタルを産業複合体形状の部品に変換する製造プロセスです切断、曲げ、溶接、表面処理、およびその他のプロセス。 その中で、シートメタルベンド 金型または cnc機器を通じて、正確な角度を達成するシートメタルの精度と効率は、コンポーネントのアセンブリの互換性とサービス寿命に直接影響します。板金製造は、柔軟性が高く、低コストの利点で製造業のイノベーションを促進し続けています。板金製造を最適化することにより、JS Companyはカスタマイズまたは大量生産であろうと、複雑な構造成分の低コスト、大量生産の革新的なソリューションを企業に提供します。

data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 1。 data-len = "230" data-v-7b79c893 = "" "> デザインとマッピング:顧客要件に従って、href = "https://jsrpm.com/3d-printing of scomfite 3d modeling of scompation of 3。 data-len = "293" data-v-7b79c893 = ""> シートメタル曲げ:精密曲げは 4。 data-len = "291" data-v-7b79c893 = ""> 溶接とリベット: Argon Arc溶接、CO₂保護溶接または耐性スポットは、href = "htps:" htps: "htps:" htps: "htps:" htps: "htps:" htps:溶接技術溶接の強度と外観の品質を確保するために、必要に応じてリベットを使用して構造の安定性を改善し、改善します。

5。 data-len = "313" data-v-7b79c893 = ""> 表面治療:会社は、砂の爆風、めっき、粉末コーティング、およびその他自動車、通信機器などのさまざまな産業の使用要件を満たすために、製品の耐食性と美的特性。 " Data-TransLateID = "6F35B8940FA68DC70B9DE3CCC04E143C" data-pos = "3" data-len = "309" data-v-7b79c893 = ""測定機器と輪郭の機器の測定基準への適合性を確保し、最終的にアセンブリと試運転を完了し、完成品配信の配信のための認定文書を提供します。

金属プレートの形成は複雑なプロセスであり、材料処理、機械的形成、精密制御などの多くのリンク、

data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" ""> 1。 data-len = "35" data-v-7b79c893 = ""> 材料の選択と前処理 2。 Data-V-7B79C893 = ""> 切断と形成 3。 data-len = "52" data-v-7b79c893 = ""> シートメタル曲げ - 構造形成のコア 曲げプロセスは、金属板の構造強度と外観の精度に直接影響します 重要な技術的困難: 4。 Data-V-7B79C893 = ""> 溶接とアセンブリ 溶接プロセス: アセンブリテクノロジー: 5。 Data-V-7B79C893 = ""> 表面処理と品質検査 表面処理: 品質検査プロセス: 溶接アルミニウム板金。 Data-V-7B79C893 = ""> プロセスの詳細と注意すべきことは次のとおりです。

1。 Data-V-7B79C893 = ""> 溶接前の準備 材料の選択と一致: er5356(普遍的なタイプ、マグネシウム5%、MIG/MAG/TIGに適しています)。

er5087(低シリコン、高マグネシウム、薄いプレートの高速溶接に適しています)。

表面処理: フィクスチャーとポジショニング: 2。 data-len = "41" data-v-7b79c893 = ""> 主流溶接方法とパラメーター data-pos = "0" data-len = "88" data-v-7b79c893 = "" "> mig/mag溶接 (1.2-6mm)。 機器構成: プロセスのハイライト: data-len = "76" data-v-7b79c893 = ""> tig溶接(タングステン吸入ガス溶接)のための薄いプレートのための(Tungsten Inert Gas Weld)。

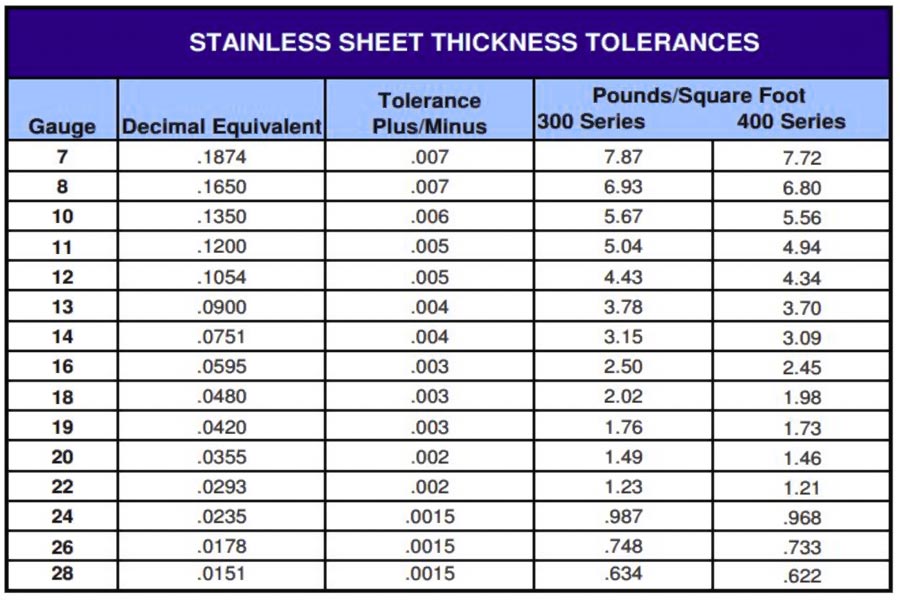

機器パラメーター: Operational skills: Laser welding is suitable for ultra-thin plates (0.1-3mm) or multilayer lap welding. Spot Welding is suitable for lap joints. 3.Critical process control Anti oxidation measures: Thermal input management: Deformation correction: 4.Post-welding treatment Quality Inspection: 5.Solutions to Frequently Asked Questions In sheet metal fabrication, the key to balance strength and cost through sheet metal gauge chart is scientific selection and process optimization: 1.Understand the relationship between sheet thickness and performance The thickness of the sheet corresponds to the actual thickness (mm/inch) corresponding to the United States Standard No. (gauge), for example: 2.Cost optimization strategy 3.Strength and cost balancing strategy 1.Technical and process capabilities: Ensure mastery of required processing techniques (e.g. laser cutting, CNC bending, welding, surface treatment, etc.) and meet accuracy and complexity requirements. 2.Equipment and material quality: Check the sophistication of equipment (e.g. CNC bending machine, automated production line, etc.) and reliability of material sources (e.g. plate thickness tolerance, surface treatment standards, etc.). 3.Quality certification and standards: Confirmation of ISO, IATF certification and compliance with industry standards (e.g. special standards in the automotive and aviation fields). 4.Production size and delivery time: Assess production capacity to meet order quantity and ensure timely delivery, especially for emergency projects requiring flexible response capabilities. 5.Cost transparency: Compare offers to avoid hidden costs by including the full process costs (e.g. design, processing and reprocessing). 6.After-sales service and support: Understand technical support response speed, warranty policy and problem solving ability. 7.Environmental protection and safety compliance: Priority should be given to production enterprises that are waste recycling, comply with emission standards and comply with safe production standards. 8.Industry reputation and case studies: Reference past customer evaluations and success stories to verify actual delivery capabilities and technical stability. When choosing a sheet metal fabricators, a comprehensive evaluation of its technical ability, quality control, industry experience and cost-effectiveness is required. As an industry-leading sheet metal processing service service provider advanced equipment, digital process optimization process optimization green manufacturing concept, JS Company provides high precision aluminum and galvanized sheet metal processing services to more than 2000 customers worldwide. Sheet metal fabrication, as the core of modern industrial manufacturing, has always been an important force for product innovation and industrial upgrading. The company relies on the full chain service capabilities, from precision sheet metal bending processing to intelligent laser cutting system, from lightweight aluminum plates to steel plates, in the durability of continuous breakthroughs. We combine material characteristics with process optimization depth. In sheet metal processing, not only the ultimate optimization of material properties, but also the perfect balance of cost control and large-scale production. With the penetration of intelligent manufacturing technologies, emerging technologies such as laser cutting, automatic bending, and 3D printing are reshaping the industry ecosystem, pushing sheet metal parts in a lighter, stronger, and smarter direction. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.Can sheet metal processing manufacture parts with complex structures? Using laser cutting and CNC bending technology to manufacture complex structural parts, its high-precision cutting and multi-angle bending ability can be combined with welding technology to achieve complex geometry from small gap to large size. 2.Will thicker boards be stronger? Increasing the thickness of the plate can improve the compressive and bending strength of the plate, but the plate is too thick (such as >10mm) and requires special processing (e.g. hot forming or hydraulic press) due to its stiffness, which makes it difficult to bend and prone to cracking. 3.Is aluminum alloy suitable for casting or sheet metal fabrication? Both are acceptable. Casting is suitable for complex internal structure and mass production, with low cost and precision. Sheet metal processing is suitable for high precision curved surface or small batch customization, through laser cutting and bending to achieve lightweight and high strength. 4.How environmentally friendly is sheet metal processing? Sheet metal processing can greatly reduce energy consumption and pollution through waste recycling (over 90% metal utilization), environmental protection processes (such as water-based spraying, powder metallurgy), and energy-efficient equipment 50% energy savings fromfiber laser cutting).

板金製造とは?

板金製造のコアプロセスは何ですか?

曲げ板金を形成する方法

が装備されています。 href = "https://jsrpm.com/bending">後続の曲げプロセス。

ow to溶接アルミニウムシートメタルにシートメタル製造?

Question

Cause Analysis

Solution Measures

Weld surface blackened

Incomplete removal of oxidizing film or inadequate gas protection.

Pre-polish until brightly coloured, increasing gas flow.

Weld porosity

High hydrogen content or excessive arc in the material.

Reduction of arc length using low-hydrogen solder wire.

Excessive welding deformation

Too much heat input or not enough stiffness of fixtures.

Reduce current/speed and switch to sectional welding.

Insufficient joint strength

Welding material does not match matrix material.

Selection of special wire such as ER5356 according to standard.

How to balance strength and cost through a sheet metal gauge chart?

What factors should be considered when choosing suitable sheet metal fabricators?

Summary

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.comFAQs

Resources

GloriaJS

迅速なプロトタイピングと迅速な製造専門家

CNC加工、3D印刷、ウレタン鋳造、迅速なツール、射出成形、金属鋳造、板金、押し出しを専門としています。

タグ:

共有します

Criticism

0 comments

Click to expand more

Featured Blogs

No data