今日のグローバルなデジタル波、プロトタイプ ing 迅速なプロトタイピングは、プロトタイプモデルを効果的に構築し、製品の概念を物理的またはデジタル形式に変換し、チームが初期段階で技術的な実現可能性と市場需要を検証できるようにします。

"v-v-79c href = "https://jsrpm.com/rapid-prototyping">迅速なプロトタイピングは、コンピューター支援設計(CAD)データと高度な製造技術に基づいて、製品の物理モデルまたは機能的プロトタイプを迅速に構築する方法です。 は、異なるニーズに応じて柔軟に選択できます。 コスト、およびチームが早期の検査機能とユーザーエクスペリエンスを達成するのを支援するだけでなく、製品の反復と最適化を加速し、生産リスクを削減します。

JSテクノロジー

jsは、< href = "https://jsrpm.com/about-us"> met±0.005mm精度要件 技術的な機能: 高リジットプロトタイプ jsテクノロジー協会: JS's CNC equipment can handle STEP/IGES files with metal prototype accuracy ±0.005mm for automotive and aviationフィールドアプリケーション。 3。 data-TranslateID = "BEC87E2F84ADCE09CD47CCF357949D6C" data-pos = "3" data-len = "21" data-v-7b79c893 = "" "> slm metal Metal Laser Direct Melting 、高強度、軽量金属成分を製造しています。 aerospace および医療インプラント

jsは、高温および腐食耐性コンポーネントの顧客需要を満たすことができ、一部の自動車顧客がR&Dリードタイムを15%短縮するのに役立ちます。

射出型はすぐに、従来の金型の開発サイクルを短くします。 href = "https://jsrpm.com/contact-us">中バッチ制作(500-5000ピース)。 相関:CNCと3D印刷技術を組み合わせて迅速な金型製造を達成することにより、産業顧客はリードタイムを40%短縮しました。

js Companyを介して cnc machining 、添加剤の製造、射出成形およびその他の技術、さまざまな材料の深い統合。迅速なプロトタイプ es の導入により、クライアントの平均プロジェクト寿命が15%減少しました。 JSの迅速なプロトタイピングサービスプロセス全体をコンセプト設計から機能的検証まで、特に精度、効率、材料のパフォーマンスを必要とするプロジェクト要件に特に適しています。

2。 data-len = "40" data-v-7b79c893 = ""> プラスチックプロトタイプ(例:ABS、ナイロン): 3。 Data-V-7B79C893 = ""> 複合材料(例:炭素繊維): 1.processability: 2.表面精度:

1。 data-TranslateID = "0B5135178D89E493471CD66B27F40DE7" data-pos = "3" data-len = "30" data-v-7b79c893 = ""

ラピッドモックアップ: 外観、サイズ、または製品設計のインタラクティブインターフェイスを迅速に構築するために使用される視覚モデルその中心的な目的は、美学、人間の相互作用ロジック、または製品設計の概念的な実現可能性を検証することです。 多くの場合、複雑な機能的または物理的パフォーマンステストを伴わないことが多いため、直感的な形式と運用体験を提供することに焦点が当てられています。 プロトタイプ電話の外観およびUI/UXインタラクションプロトタイプ。 迅速なプロトタイピング: 機械コンポーネント。 材料強度や熱散逸効率などの実際の使用およびテストエンジニアリングインジケーターをシミュレートする必要があります。 href = "https://jsrpm.com/industry/industry-equipment"> gearコンポーネントおよび cnc Machining電子住宅プロトタイプ

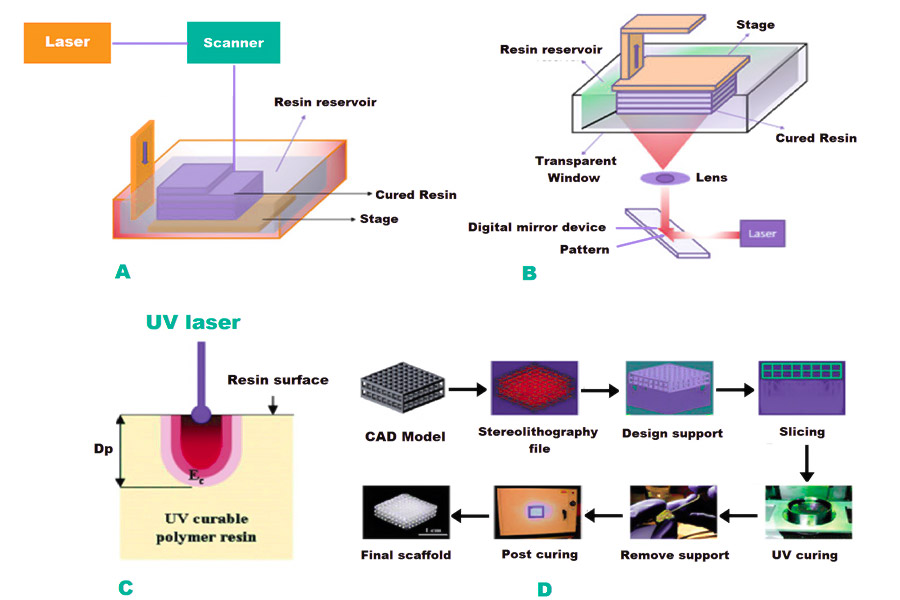

3.アプリケーション段階 The core difference between a Rapid Mockup and a Rapid prototype is the target phase and application phases. The Mockup is quickly conceptualized through low-cost materials and is suitable for early design review. Rapid prototyping, which verifies core structural strength and assembly accuracy through precision manufacturing, is commonly used for intermediate testing and mass production preparation. 1.Clarify requirements and objectives First, the purpose of the prototype (such as functional testing, appearance display or structural verification) needs to be determined, as well as the requirements for accuracy, strength, surface quality, etc. For example, rapid prototype can prioritize 3D printing (such as FDM or SLS) if rapid verification of a mechanical structure is required, or CNC machining or silicone replication if high-precision appearance models are required. 2.Material compatibility Analysis Process selection is based on the characteristics of the prototype material, such as high temperature resistance, flexibility or electrical conductivity. For example, metal parts require selective laser melting (SLM), while transparent parts can be made using resin photopolymerization (SLA) or CNC cutting. 3.Process matching principles 4.Cost and time balance Low-complexity prototypes can use low-cost processes (such as desktop FDM), while high-precision requirements require investment in industrial-grade equipment (such as five axis CNC). At the same time, it is necessary to assess post-treatment time, such as the need for cleaning and secondary curing of SLA. 5.Technical validation and iteration The feasibility of the design is verified by rapid sampling and the process parameters are adjusted according to the test results. For example, metal casting prototypes require multiple adjustments to the mold, while 3D printing can quickly modify model files. 6.Technology integration and automation Combining CAD/CAM software to optimize processes such as topologically optimized CNC machining paths directly generated, or AI algorithms to predict 3D printing the deformation and compensate in advance. The core value of traditional engineering design is irreplaceable 1.Systematic design framework: Traditional engineering follows a systematic process of requirements analysis, conceptual design, detailed design, and verification testing to ensure the integrity and reliability of the product from concept to implementation. For example, car airbags must be designed in strict compliance with collision testing standards, and rapid prototyping alone cannot replace rigorous simulation and verification. 2.Risk control capability: Traditional engineering avoids design defects through multiple rounds of reviews, fail-pattern analysis (FMEA), and other processes, while relying solely on rapid iterations can lead to key issues (such as compliance risks for medical devices) being overlooked. Rapid prototyping overcomes limitations of traditional engineering 1.Accelerated validation and iteration: Rapid prototyping shorten the validation process from a few weeks to a few days by quickly creating physical or digital models. 2.Reducing trial and error costs: In traditional engineering, design errors can lead to higher die scrap costs; waste of resources can be avoided by pre-verifying low-cost prototypes,such as FDM plastic parts. JS company has helped customers detect structural strength issues through prototype testing, saving 30% on late rework costs. Synergistic application scenarios for both Rapid prototyping is an accelerator, not a substitute for conventional engineering thinking. It helps engineers validate innovative ideas faster by shortening iteration cycles and reducing trial and error costs, but core design logic, safety standards, and system processes still rely on traditional engineering thinking. The combination of the two is the key to efficient innovation and reliable implementation in modern manufacturing. 1.Full chain rapid prototyping solution 2.Rapid delivery and iteration capability 3.Precise investment and resource optimization 4.Quality reliability verification 5.Sustainable development 6.Recognition of success stories Rapid Prototype is a fast method to visualize product concepts and validate functions. At its core, abstract ideas can be quickly turned into interactive physical or digital samples utilizing techniques such as 3D printing and CNC. Whether in industrial manufacturing, consumer electronics, or healthcare, Rapid prototyping not only shortens the life cycle of a product from concept to market, it also promotes interdisciplinary collaboration and innovative thinking. With the continuous advancement of technology, Rapid prototyping will continue to be an important engine of product innovation, enabling all industries to break through the boundaries of traditional development models. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.Why the rapid prototyping? Rapid prototyping saves time and costs by quickly validating design concepts, identifying potential problems in advance, reducing development risks, promoting team collaboration and user feedback, and avoiding direct investment in developing immature products. 2.Does rapid prototyping require repeated modification? need. Repeatedly modify the verification function and adjust the design to ensure that the final product meets the requirements while improving development efficiency and user experience and avoiding large-scale rework in the later stages. 3.What are the advantages of 3D printing in rapid prototyping? The advantages of 3D printing in rapid prototyping are: mold free rapid prototyping, support for single-use molding of complex structures, wide material selection (plastics, metals, resins, etc.), low cost and time saving, especially for small batch trial production and design iteration optimization. 4.What common problems do rapid prototype encounter during production? Insufficient accuracy (error ±0.05mm or more), surface roughness requiring secondary processing, limited material strength, additional support for complex structures, high small batch costs, poor design adaptability, short lead times, fragile structures requiring advance planning of processes and material selection.

迅速なプロトタイピングとは?

迅速なプロトタイピングの技術的なパスは何ですか?

1。 data-len = "56" data-v-7b79c893 = ""> 金属プロトタイプ(例:アルミニウムおよびチタン合金):

1。 data-len = "56" data-v-7b79c893 = ""> 金属プロトタイプ(例:アルミニウムおよびチタン合金):

迅速なモックアップと迅速なプロトタイピングの違いは何ですか?

dimension

rapid mockup

迅速なプロトタイピング

ツール/テクノロジー

マニュアルモデリング(粘土、泡)、2D/3Dモデリングソフトウェア(SketchUp、figma)。

CNCマシン、3D印刷(SLA/FDM)、シリコン型鋳造。

素材

非機能材料(段ボール、プラスチックシート、木材)。

機能材料(金属、エンジニアリングプラスチック、複合材料)。

複雑さ

low(外観または基本構造のみ)。

high(機械的、熱的要件、その他のパフォーマンス要件を満たすため)。 >

ステージ

rapid mockup

迅速なプロトタイピング

初期段階

✔️コンセプト検証(例:製品スタイリングレビュー)。

❌通常、モックアップ後。

midium stage

❌

✔️Functional testing (e.g. buttons and waterproofing).

Later-stage

❌

✔️Small batch trial production (e.g. final confirmation before production).

How to match suitable processing techniques in rapid prototyping?

Will Rapid prototyping replace traditional engineering design thinking?

Stage

Traditional engineering design

Rapid prototyping

Concept validation

Requirement documents, sketches, preliminary simulations.

Handmade models, low-cost 3D-printed parts.

Functional verification

Detailed design, engineering drawings and testing of key components.

CNC machining prototype, silicone mold casting.

Mass production preparation

Full size inspection, process curing, supplier audit.

Small batch trial production production, material certification.

Why choose JS as your prototype partner?

要約

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com FAQS

Resources