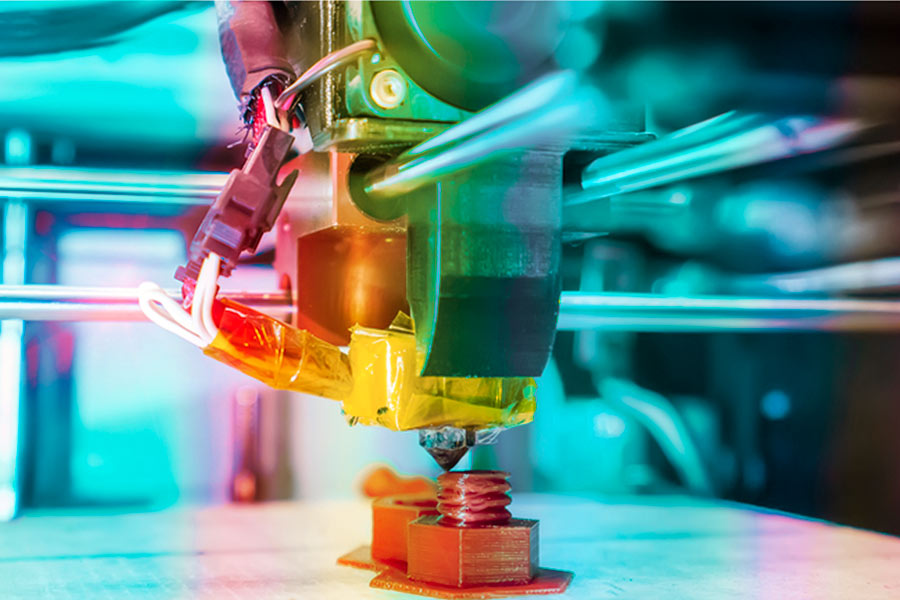

3D印刷は、互いに既知の製造として既知の上にそれらを重ねることでデジタルオブジェクトにデジタルオブジェクトに変換する高度な製造技術です。 3 d 印刷は、3D SCANデータなどのCAD設計モデルまたはコンピューターデザインから直接3Dエンティティを生成します。そのコアテクノロジーには、光重合(SLA)、溶融堆積モデリング(FDM)、および選択的レーザー焼結(SLS)が含まれます。プラスチック、金属、セラミック、さらには生体材料に柔軟に対応し、産業用プロトタイプ、医療モデル、航空宇宙コンポーネント、パーソナライズされた消費財で広く使用されています。

JS Companyは長年にわたって3D印刷サービスに深く関わっており、顧客にワンストップソリューションを提供しています。それが精密3Dモデル印刷の需要であるか、複雑な構造機能成分の製造であるかどうか、JS会社は高品質で効率的なカスタマイズを実現できます。

3D印刷とは?

3D印刷は、デジタルモデルに基づく多層材料積み重ねテクノロジーです。 data-len = "177" data-v-7b79c893 = ""> CADデザインまたは3Dスキャンで3Dモデルを作成し、機器を使用してプラスチック、金属、その他の材料層ごとに層ごとに固体オブジェクトに型を形成します。 中空のグリッドや不規則な表面などの複雑な幾何学的構造をすばやく製造します。

3Dプリントモデルは、正確な適応のために患者の骨またはチタン合金ジョイントを印刷するために使用されます。 コンポーネントの小さなバッチの小さなバッチなど、href = "https://jsrpm.com/industry/aerizedustry/aerized scaffolds ケーシング。

3D印刷材料を選択する方法

一般的な産業用アプリケーションシナリオと技術的特性を組み合わせて、3D印刷材料の選択について次の推奨事項が作成されます。

1.テクノロジーの材料の選択

<テーブルスタイル= "境界線 - 崩壊:崩壊;幅:100.282%;境界線幅:1px;境界線:#000000;高さ:292.812px;" border = "1">2.材料の特性に応じた

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線幅:1px;境界線:#000000; height:342.766px;" border = "1">3.キー選択決定要因

機械的プロパティ

- 強度要件:ナイロンとメタルが優先。

- 温度抵抗:abs(80-100°C)vs pa(120°C+)。

コスト制御

- 迅速な検証:pla/fdm推奨。

- 精密生産:オプションの光感受性樹脂または sls nylon 。

投稿要件処理

- ペイントなし:金属/セラミック

- カラーカスタマイズ:マルチカラーABS/PLAフィラメント。

さまざまなタイプの3D印刷技術の違いは何ですか?

さまざまなタイプの3D印刷技術の違いは何ですか?

3つの主流のコアの違いの比較 3D印刷技術:

1。 コアプロシージャの比較

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線幅:1px;境界線:#000000; height:239.469px;" border = "1">2。 技術的な利点と短所の比較

<テーブルスタイル= "境界線崩壊:崩壊;幅:100%;境界線:1px;境界線:#000000;" border = "1">

jsの産業用グレードFDM機器は±0.05mmの高精度を達成できます。

高精度モデル:SLAフォトカルチレイヤーの厚さは0.025mmおよび Sprade-greadness up to span

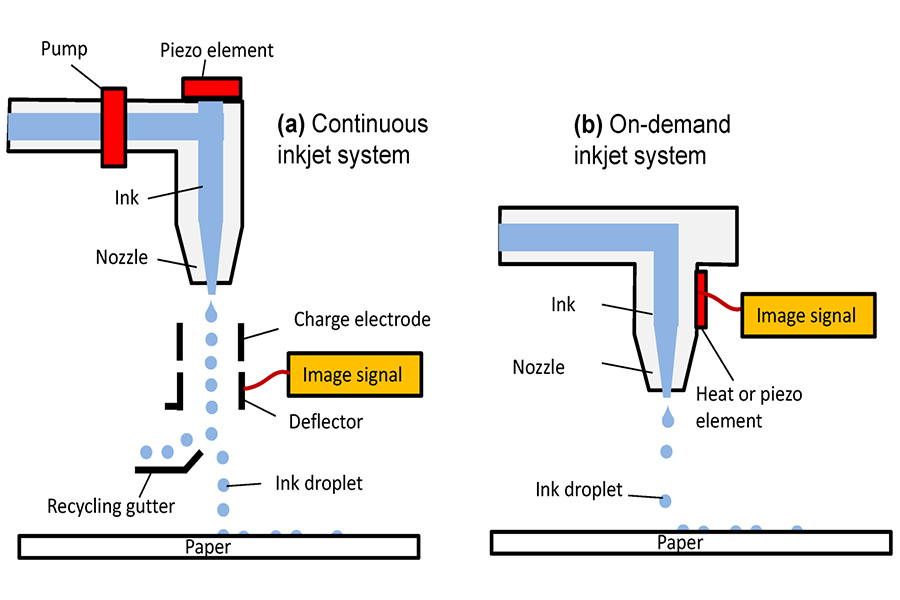

インクジェット印刷は、複雑な構造製造、パーソナライズされたカスタマイズ、高性能部品の生産における重要な技術になりました 以下: 1.高精度と細心のパフォーマンス

3.Efficient production and rapid iteration 4.Physical diversity and innovation 5.Technical constraints and improvement directions Technology Strength Assessment 1.Advanced equipment 2.Material adaptability Service Capability Verification 1.Design support 3.Post processing support Quality control system 1.Accuracy verification 2.Reliability testing Cost transparency 1.Quotation details 2.economies of scale Priority should be given to service providers with more than 100,000 hours of printing per year (JS has a large-scale production line that reduces marginal costs). Cases and reputations 1.Industry case studies 2.Client reviews Viewing user feedback through industry forums or third-party platforms such as G2 focuses on on-time product delivery and aftermarket response (JS official website shows 98%% customer satisfaction). 1.Industrial-grade precision manufacturing: Equipped with SLA light curing equipment (±0.02mm accuracy), industrial FDM (±0.05mm), SLS nylon printing supports 100% density to 20% crystal lattice free adjustment with 40% weight loss and constant strength. 2.Comprehensive material compatibility: Includes engineering plastics (ABS/PLA), metals (titanium alloys), ceramics, biodegradable materials and conductive silver ink, supporting parameterized material selection (e.g. PEEK resistance to temperatures below 300°C). 3.Cost optimization and small batch customization: By combining 3D printing and injection molding processes, large-scale production costs can be reduced to 60% of traditional methods, especially for small orders of 100-1000 pieces. Water-soluble auxiliary materials can reduce reprocessing costs by 70% and delivery cycles by 30%. 4.Full Chain Digital Services: From CAD modeling to finished product inspection, 18 node data loops ensure 100% restoration of design intent. 5.Global Service Network: We provide 3D printing services to a number of countries worldwide. For small orders (≤100 pieces), delivery can be made as soon as 48 hours. For medical emergencies, we promise 24-hour fast delivery. The bilingual engineering team provides remote assistance such as model restoration and parameter optimization. 3D printing, at the heart of additive manufacturing, is reshaping global manufacturing landscape. It overcomes the limitation of traditional subtractive manufacturing processes, and enables numerous fields with its advantages of high precision, flexibility and low cost. From biocompatible implants to lightweight aerospace components, from personalized consumer electronics to complex industrial prototypes, 3D printing not only accelerates product iteration, but also facilitates frontier expansion in innovative design and functionality. In the future, 3D printing will continue to drive industrial upgrading as smart manufacturing and green manufacturing are deeply integrated. JS helps enterprises achieve personalized, efficient, low-carbon manufacturing and redefine global industry chain values through multi-material collaborative printing and hybrid manufacturing. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.How can 3D printing reduce material waste? Traditional manufacturing often requires cutting and engraving, with a waste rate of 30% -50%. 3D printing is additive manufacturing, which involves printing only the parts needed, with a material utilization rate of over 90%. It is particularly suitable for small or complex production. 2.What is the best FDM printing layer thickness setting? The prototype is rough, with layers of 200-300 microns (0.2-0.3 mm) thick, fast but rough on the surface. The model is excellent, with layers 50-100 microns (0.05-0.1 mm) thick, better detail and longer processing time. 3.Are SLS-printed powder materials reusable? SLS-printed powder material can be reused, but after repeated use, its flowability decreases and their strength decreases わずかに。 The recovery rate of metal powder can be over 90%, and the number of uses needs to be controlled according to the material type to ensure performance. 4.Is 3D printing expensive? Small plastic printers for home use range from $280 to $1,400, and are suitable for DIY and small batch production. Mass production relies on industrial-grade metal/high-performance printers, requiring tens of thousands to millions. 3D印刷モデルが従う必要がある基本的な設計原則は何ですか?

3D印刷モデルが従う必要がある基本的な設計原則は何ですか?

層の厚さと印刷速度の効率と精度のバランスをとる方法

3D印刷でのインクジェット印刷の重要性は何ですか?

How to evaluate the professionalism of a 3D printing shop?

Five reasons to choose JS company's 3D printing services

Summary

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.comFAQs

Resources