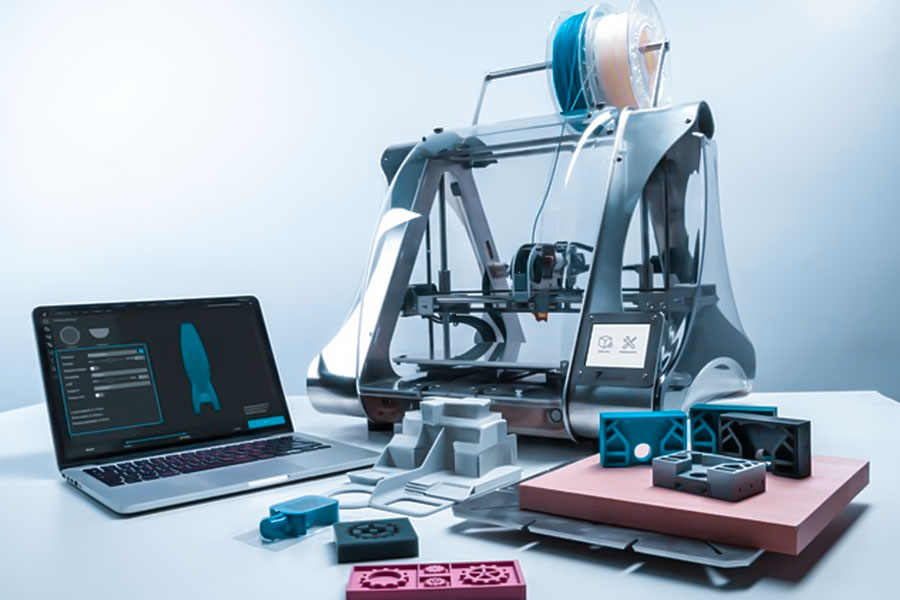

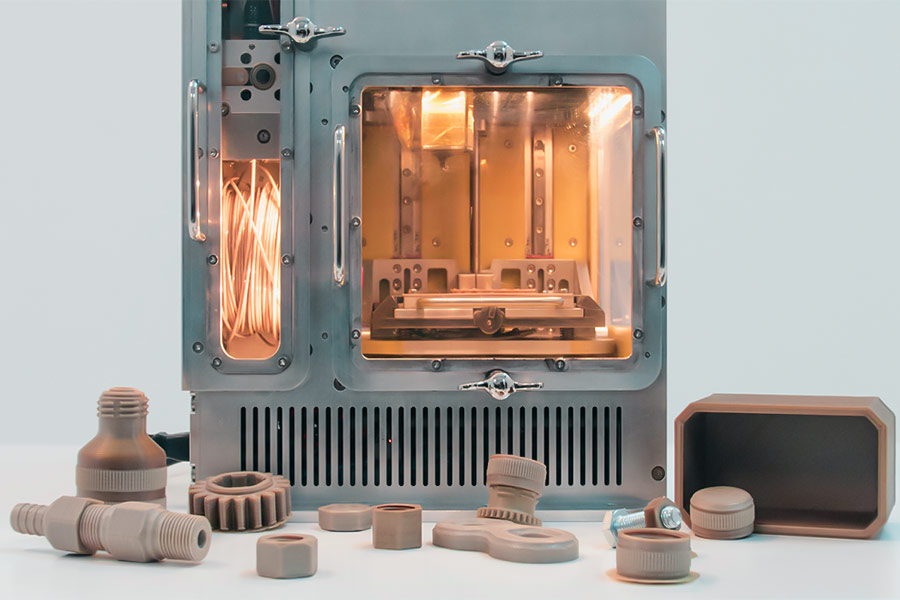

La technologie d'impression 3D remodeance la logique de la production avec la fabrication numérique. provenant du prototypage rapide des engrenages industriels et des squelettes personnalisés pour une utilisation médicale pour Fabrication. En tant que lien entre la conception et la production, les modèles imprimés 3D sont devenus des outils efficaces pour la créativité valorisante. js fournit des services d'impression 3D professionnels Couving FDM, SLA, SLS et processus d'impression métal , soutenant tout, du développement prototype à la production de petits lots et aidant les innovations.

1.Fused Modélisation de dépôt (FDM) 2.Sterreolithography (SLA) 3. Dé frittement laser sélectif (SLS) 5. Comparaison de la compression 3D Irgure 3D Technologies 1.La la couche est épaisse, plus l'adhésion intercouche 2. La couche épaisse, la structure la plus dense Effet de l'épaisseur de la couche

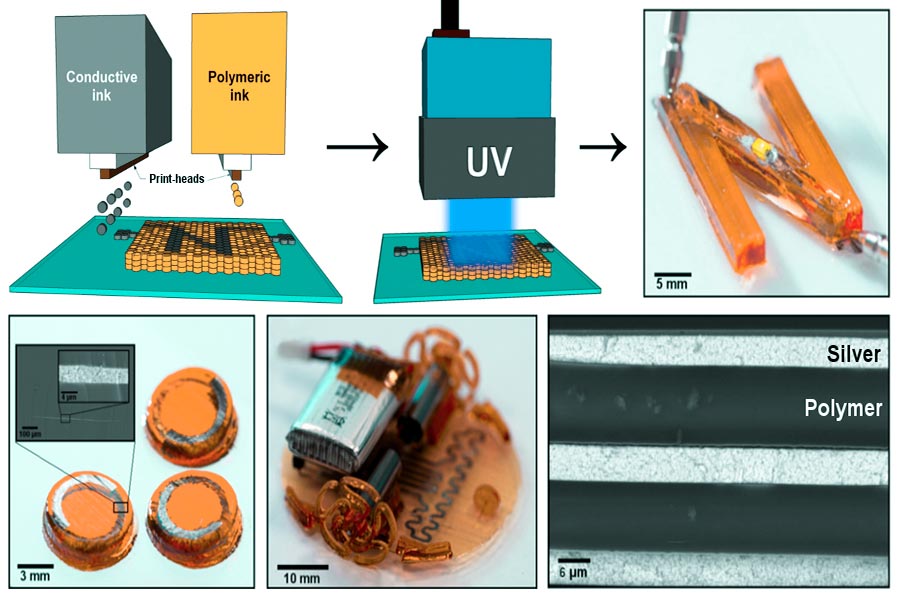

équilibre entre l'épaisseur de la couche et les propriétés du matériau 1. Les couches d'épouses économisent du matériel mais la résistance du sacrifice 2. Les couches minces ajoutent de la force mais prenez plus de temps à imprimer Sélection d'épaisseur de couche dans les applications réelles 1. Parts fonctionnels par rapport aux pièces d'affichage 2. Adaptation de la propriété de la support 1. Type de source lumineuse et taille speckle 3. Épaisseur de couche (résolution de l'axe z) 5. Complexité de géométrie du modèle Tableau de suggestion de comparaison et d'optimisation des paramètres By properly selecting parameter combinations, the 3D printing model can achieve precise manufacturing from concept verification to functional prototypes. 1.3D printing of metallic materials (high temperature environment preferred) SLM/DMLS (selective laser melting/sintering) 2.Ceramic 3D printing technology (ultra-high temperature resistance potential) SLA/DLP (light-curing ceramics) 3.High-Performance engineering plastic 3D Printing FDM (Molten deposition modeling) SLS (selective laser sintering) Technology selection recommendations for high temperature scenarios Ink jet printing technology is by layering liquid material on top of each other to create three-dimensional objects. Its core lies in high high-precision jetting and curing contrôle. Specific implementation steps and key technologies are as suit: 1.Preparation of materials: Adaptation of liquid media 2.Ink jet print head: Precision droplet injection Piezoelectric drive or thermal foaming technology: 3.Layer by layer stacking: droplet solidification molding 4.Post-treatment: enhancement and surface optimization 1.Structural adaptation principle Overhang structure (>45°): Bridge structure (long span): 2.Matching and separation of materials Easy peel combination: Chemical dissolution combination: ABS+HIPS: Lemonin is needed to dissolve the scaffold and is suitable for complex internal parts such as gear components. 3.Actual performance requirements 4.Post-treatment efficiency Quick removal: Environmental Protection Plan: It is advisable to select biodegradable scaffolds (e.g. PBDE-based biodegradable materials) to reduce waste liquid treatment costs. 5.Printer adaptation FDM equipment: SLA/DLP equipment: 1.Multi-material printing technology support JS's 3D printing services include MJF and composite metal/ceramic printing technologies, which can switch different materials (e.g. metal-ceramic, carbide-polymer) during the same printing process to achieve continuous or segmented gradient changes in material composition. 2.Material compatibility and gradient design Through JS's 3D printing services, customers can choose from a variety of material combinations, including metals, ceramics and composites, and freely design the microstructure of functional gradient components (such as abrasionresistant + substrate layer). 3.Process optimization and performance assurance JS's industrial-grade equipment supports thickness control (±0.005mm) and temperature management to ensure uniform interface bonding strength and gradient transition across different materials and meet extreme working conditions such as high temperature and pressure. 4.Customized solutions For areas such as aerospace and medical devices, JS's team can provide a full range of services, from material selection and gradient structure design to reprocessing, such as: As a disruptive technology, 3dprinting continues to drive change in manufacturing with its diverse process types (e.g. FDM, SLA, metal printing, etc.) and a wide range of application scenarios (from industrial manufacturing to medical innovation). Whether it is the efficient production of complex functionally gradient parts or the rapid iteration of custom models, 3D printing services demonstrate irreplaceable flexibility and economy. Technology service providers represented by JS have further lowered the technology threshold by integrating multi-material printing, precision process control and industry-wide chain support, allowing businesses to focus on design innovation and value creation. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. Pour plus de confirmation, Veuillez contacter notre équipe de service client pour un support professionnel. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.Does SLS printing require support? SLS printing usually does not require support. The unsintered nylon powder will naturally envelop the model to avoid collapsing in the air. Only a few complex designs require a small amount of ancillary support, which greatly simplifies the reprocessing process. 2.Which technology is suitable for printing transparent parts? SLA technology is suitable for printing transparent parts. It uses photosensitive resin that hardens under UV lumière. The surface is smooth and transparent. Suitable for making high precision transparent model (such as optical parts). 3.What does the layer thickness of FDM affect? The thickness of FDM layer influences surface smoothness, printing time and printing strength. The thicker the layer, the more visible the pattern, the faster the printing, but the intensity may be reduced. 4.How big a part can 3D printing make? Industrial-grade 3D-printing devices can manufacture large parts of meters (such as aerospace parts), while desktop devices are usually limited to a few dozen centimeters and are suitable for small models or prototypes. GloriaJS Expert en prototypage rapide et fabrication rapide Spécialiser dans l'usinage CNC, l'impression 3D, la coulée d'uréthane, l'outillage rapide, le moulage par injection, la coulée de métal, la tôle et l'extrusion. Étiqueter: p> plier = "600"> p> "Hight)

p> plier = "600"> p> "Hight)

Quels sont les types de technologies d'impression 3D?

Type de technique

Speed

coût

Type de matériau

Capacité de traitement de la complexité

Avantages associés de la société JS

fdm

Medium

Low

des plastiques tels que PLA et ABS.

★★★ ☆

Vitesse d'optimisation du processus de production efficace.

sla

Fast (DLP)

Centre

Résine photosensible.

★★★★ ☆

Match à haute précision JS ± 0,005 mm Standard.

sls

Medium

Centre

Nylon, TPU et autres poudres.

★★★★ ☆

Soutenir l'expansion des applications métalliques / composites.

MJF

extrêmement rapide

moyen-élevé

Nylon (PA12 / PA11).

★★★★★

Amélioration de l'efficacité de la production par lots pour la livraison rapide.

slm

Slow

Tall

Métal de poudre (titane, acier inoxydable).

★★★★★

La technologie d'usinage de précision assure une forte complexité des pièces.

Quel est l'effet de l'épaisseur de la couche d'impression FDM sur la résistance?

Quels paramètres déterminent la résolution d'impression SLA?

Paramètres

Impact sur la résolution

Direction d'optimisation

valeur typique

Type de source lumineuse

Laser> DLP (Laser a une précision plus élevée à la même résolution).

Choisissez le laser pour les modèles de précision et le DLP pour la production de masse.

Laser: 50μm / dlp: 100 μm

taille de spot

Plus le spot est petit, plus les détails sont clairs.

Utilisez des têtes laser de haute précision ou une projection DLP 4K.

50 μm (laser)

vitesse de balayage

Plus la vitesse est lente, plus le durcissement est lent.

Réduisez la vitesse dans les zones fines (par exemple 0,1 mm / s) et accélérez dans de grandes zones.

50-200 mm / s

Épaisseur de couche

L'épaisseur de la couche est divisée par deux et la résolution de l'axe Z est augmentée de 4 fois.

Utilisez des couches minces (25 μm) pour les pièces de précision et les couches épaisses (100 μm) pour l'augmentation de la vitesse.

50 μm (standard)

Viscosité de la résine

La faible viscosité améliore la fluidité et la capacité de remplissage des détails.

Use special resins (e.g. transparent resins with viscosity ≤1500cP).

500-2000cP

Model overhang angle

If the angle is too small, dense support is required, and blocking the light affects the curing.

Avoid <45° overhangs or add auxiliary supports in the design.

≥60° (unsupported)

Which printing technology is more stable in high temperature environments?

Scene temperature

Recommended Technology

Avantages de base

Key capabilities of printing shops

600-1000℃

Metal SLM/DMLS.

High strength and creep resistance.

Laser equipment, vacuum environment, heat treatment.

1000-1500℃

Ceramic SLA/DLP.

Ultra high temperature resistance and corrosion resistance.

Specialized ceramic materials and high-temperature sintering process.

200-600℃

PEEK FDM, Nylon SLS.

Economy and lightweight.

Industrial grade equipment and material modification.

How to achieve layered stacking in 3D ink jet printing?

How to choose supporting materials for complex 3D printing models?

Can JS achieve functionally graded components through multi material 3D printing?

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources

Blogs connexes

Criticism

Featured Blogs

Partager

0 comments

Click to expand more

PRÉCÉDENT

Qu'est-ce que l'impression 3D?

Mar 28 2025

SUIVANT

Quels sont les types d'impression 3D?

Apr 24 2025

No data

Contact