hoja m etal f abraza es el proceso central de giros Procesamiento de hojas de metal En componentes industriales de precisión. Corte, Las hojas de flexión de metal y la tecnología de ensamblaje de precisión se utilizan ampliamente en automotriz, electrónica, construcción y otros campos. Si la producción de chapa galvanizada o el procesamiento de chapa de aluminio ligero es inseparable de equipos y tecnología avanzados. Desde el diseño inicial hasta el producto final, se requieren controles precisos en cada paso para garantizar que el producto cumpla con los estrictos estándares de calidad. Ya sea piezas de precisión pequeñas o Grandes bastidores de equipos El procesamiento de chapa ha sido un enlace básico indispensable en la industria moderna.

¿Qué es la fabricación de chapa?

Convertir las hojas de metal plano en la forma deseada a través de corte de metal, estampado, soldadura y otros procesos. El núcleo de la máquina de la máquina de la mora, la muerte y el otro equipo a exert. href = "https://jsrpm.com/contact-us"> lograr la flexión de chapa de precisión y fabricar piezas estructurales para cumplir con los requisitos de diseño. The process is widely used in Piezas de automóviles , carcasas de equipos mecánicos, componentes del edificio, etc. Tiene las ventajas de alta eficiencia de producción y bajo costo.

"iMg class =" no-wrap " src = "https://jsrpm.com/webSite_img/i/2025/04/07/nwi9mn-2.jpg" alt = "comprender la fabricación de chapa" width = "900" altura = "600">

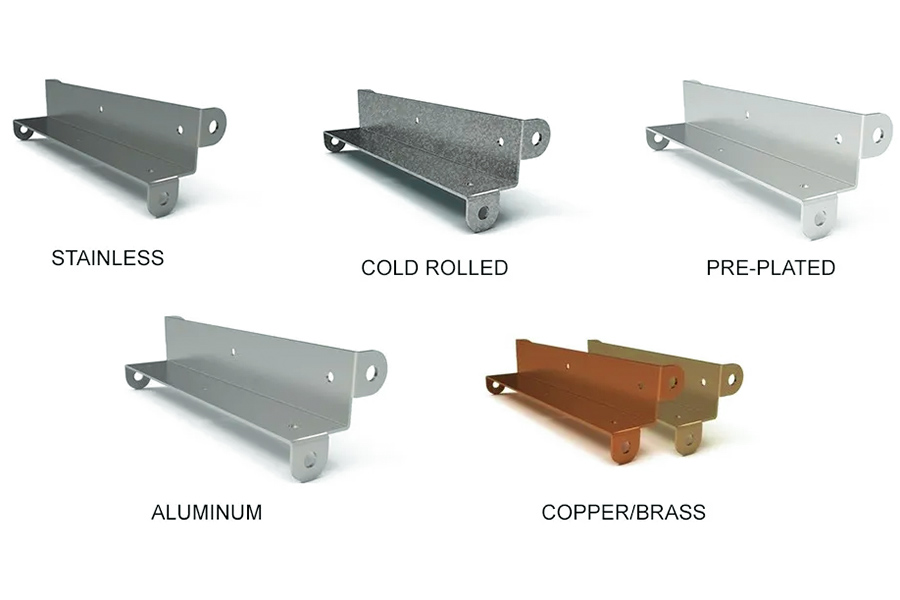

¿Cómo elegir materiales para la fabricación de chapa metálica?

Play metal procesamiento se encuentra a través de la reducción, el estampado,

resistencia y ductilidad: el acero es duro pero quebradizo y requiere más fuerza de flexión, el aluminio es suave y fácil de dar forma para la flexión compleja (por ejemplo, Adaptabilidad del tratamiento de superficie : la hoja galvanizada tiene resistencia de óxido, pero tensa a aparecer en el borde blanco después de la agitación, mientras que el acero sin correos ha corregido, pero requiere una alta residencia rebotada, pero requiere una alta residencia rebotada, pero requiere un alto reembolso rebotado. compensación.

2. Requisitos de escenario de aplicación

- requisitos livianos: mazings electrónicos y Requisitos de resistencia a la intemperie: el equipo exterior (como las farolas) debe estar hecho de lámina galvanizada o acero inoxidable para resistir la corrosión y la oxidación.

- escenario de conductividad: el cobre es el material preferido para el calor de la placa de circuito de circuito, lo que lleva una alta eficiencia de disipación de calor y alta conductividad.

3. Optimization of process adaptability

- Precise control of sheet metal bend: Use a CNC bending machine preset rebound value (such as 1-2 degrees of stainless steel compensation) to ensure accuracy of ángulo.

- molde-plate coincidente: para placas delgadas (≤2 mm), Las herramientas de corte nítidas se utilizan para reducir BURR , para placas gruesas (≥ 5 mmmment, se requieren que el paso es el paso de los 5 mm), se requieren que las herramientas nítidas se utilicen. Cracking.

Cost-benefit savings

- Comparación de costos de material: acero al carbono ordinario El precio más bajo, la aleación de titanio tiene el mayor costo y debe tener en cuenta el rendimiento y el presupuesto.

- tasa de pérdida de procesamiento: para piezas irregulares , los materiales de plasticidad sólidos (al igual que la lámina de cobre) debe preferirse para reducir las tarifas de desperdicio.

¿Cuál es el proceso de fabricación de chapa?

modelado 3D completo utilizando software especializado como SolidWorks/Inventor.

"Bending de precisión

Comparación de los parámetros de flexión Diferencias Hoja galvanizada y Hoja de aluminio Rebound compensation control

¿Cuáles son las diferencias en los parámetros de flexión entre la lámina galvanizada y la hoja de aluminio?

parámetros/materiales

chapa galvanizada

chapa de aluminio

tendencia de rebote

pequeño rebote (la capa galvanizada aumenta la rigidez del material).

El rebote es grande (el valor de compensación debe aumentar).

Radio de flexión recomendado

Radio mínimo ≥0.5t (t es grosor de la placa).

Radio mínimo ≥1.0t (para evitar grietas).

Sensibilidad a la temperatura

La flexión en frío es estable.

La flexión de alta temperatura se suaviza fácilmente (el tratamiento de temperatura ambiente es mejor).

tasa de desgaste de moho

La pérdida de fricción de la capa galvanizada acorta la vida útil de la matriz en aproximadamente un 20%.

Las virutas de aluminio se adhieren fácilmente a los moldes (requieren que se limpien regularmente).

Control de ángulo de curvatura

La compensación de rebote recomendada es 0 ° -1 °.

El valor de compensación de rebote debe reservarse a 1 ° -3 °.

dificultad para tratar burrs

Las rebabas de la capa de zinc son propensas al desapego.

Las rebabas de aluminio deben ser finamente pulidas.

diferencias en la ductilidad

baja ductilidad (fácil de romper).

alta ductilidad (para formas complejas).

tratamiento de resistencia a la corrosión

pasivación y óxido inmediatamente después de doblar.

Se requiere protección anodizada o rociada .

¿Qué herramientas son cruciales para la fabricación de chapa?

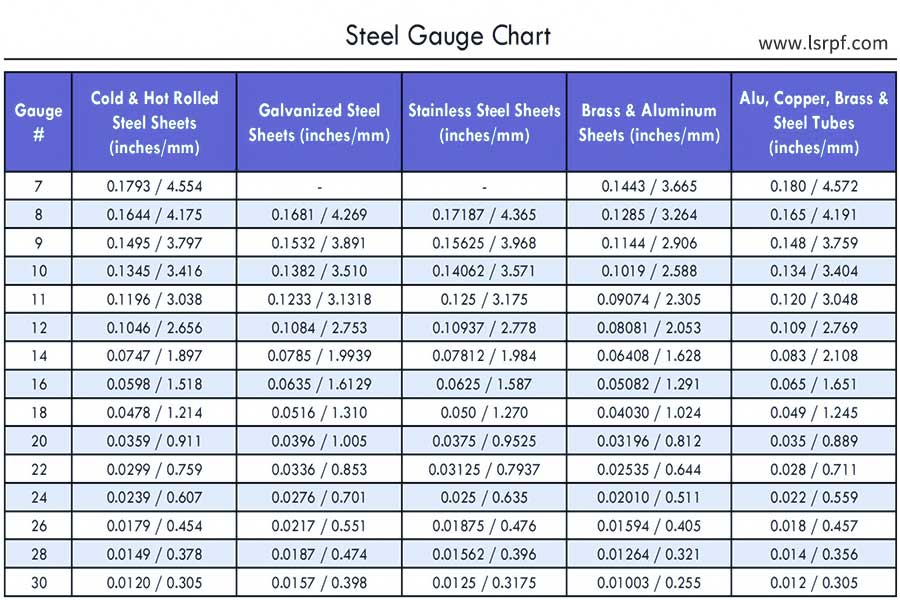

The following are the basic tools and techniques of sheet metal processing, combining the guidance of the sheet metal gauge Gráfico:

1. herramientas de corte

- Laser Cutting Machine: Suitable for thin plates (≤6mm) with accuracy ±0.02mm. See thickness chart for power and focus selection.

- CNC punch: For medium thickness plates (1-8mm), the thickness map parameters (e.g. punch spacing, plate thickness ratio, etc.) are matched through the mold library.

- Plasma/waterjet cutting: applies to thick plates (>8mm), adjusting cutting speed and air pressure through thickness chart to reduce thermal deformation.

2.Bend tools

- Bend machine: Adjust the opening angle of the V-shaped groove according to the sheet metal gauge chart (e.g. 1.5mm aluminum plate requires an opening angle of 88° for V-shaped groove).

- The gap between the lower molds should be set according to the formula (gap= thickness * coefficient) to prevent the galvanizing layer from peeling or aluminum from cracking.

- Roll bending machine: For cylindrical/curved parts, choose roller spacing and feed speed according to thickness diagram.

3.Forming mold

- Stretch molds: For deep presses (such as car coverings), mold fillet radius (≥1.5T is selected based on thickness diagram).

- Round rolling die: When rolling a sheet (≤2mm), pre-lubricating oil is needed to reduce friction coefficient.

Metal plate connection tools and techniques

MIG/TIG welding machine:

- Thin plates (≤3mm) are welded with pulses to avoid burnout (current range 50-150A).

- The thickness plate (>3mm) is welded in several layers and the temperature and weld spacing between the layers are determined in accordance with the thickness diagram.

Laser welding: Precision components,such as electronic components, require adjustment of spot diameter and focus.

2.Riveting tools

- Rivet gun: Select rivet diameter to match plate thickness.

- Hydraulic riveters: Calibration pressure values (≥8 tons for 3mm plates) are required for heavy duty plates (e.g. stainless steel).

3.Adhesive technology

- Epoxy resin adhesives: For sheet adhesives (such as electronic device casings), the thickness of the adhesive layer (0.1-0.3mm) should be controlled.

- Structural adhesive: When splicing thick plate, it must be combined with the curing schedule.

What do sheet metal fabricators do?

Core players in the industry

1.Key links in the industrial chain

- Upstream undertaking: Coordination of steel, non-ferrous metals and other raw material suppliers to ensure stable supply of plate.

- Downstream support: Precision metal components for automotive, electronics, home appliances, aerospace and other industries are fundamental to manufacturing supply chain.

2.Technology Transformation Hubs

- Translating customer requirements (e.g. CAD drawings, samples) into scalable production process solutions.

- Combine materials science and mechanical engineering knowledge to solve complex structural design and processing problems.

3.Customized solution providers

- According to the demand of different industries, the development of differentiated products and high-end, environmental protection industries, automobile covering parts, medical equipment casings, communication base station sheet metal accessories and so on have set up pilot projects.

- Provides flexible manufacturing capabilities from prototype design to mass production.

4.Standardization promoters

- Compliance with ISO, ASTM and other international standards to ensure product quality consistency.

- Promote industry process standardization (such as bending tolerance, welding specifications, etc.) to improve overall manufacturing level.

Core responsibilities of the industry

1.Quality and safety assurance

- Strict control material inspection (e.g. chemical composition inspection, mechanical performance inspection).

- Implement full process quality control (e.g. size accuracy, surface defect detection) to ensure that products meet safety standards (e.g. compressive strength, corrosion resistance).

2.Driven by technological innovation

- Advanced laser cutter and robot bending system are introduced to improve processing efficiency and accuracy.

- Development of green manufacturing processes (such as lead-free soldering and environmentally friendly surface treatment) to reduce energy consumption and pollution.

3.Cost and efficiency optimization

- Reduce cardboard waste (typically utilization rate ≥85%) through intelligent typesetting software.

- Optimize production processes (such as automatic loading and unloading, process linkage), shorten delivery cycles.

4.Responsibility for sustainable development

- Promotion of circular economy (e.g. waste recycling, waste heat recovery, etc.).

- Reduction of carbon emissions (e.g. use of EDM instead of traditional flame cutting).

How do global and local factors affect sheet metal fabrication?

1.Global drivers

- Technological innovation: Automation (robotic bending), promotion of new materials (aluminium/titanium alloy), improvement of accuracy and efficiency.

- Economic volatility: Raw material prices and tariff policies,such as the U.S.-China trade friction that has caused North American sheet metal companies to turn to local or Southeast Asian suppliers, have forced supply chain localization to localize.

- Environmental pressure: Global carbon reduction targets promote green manufacturing, such as requiring sheet metal companies in the Los Angeles area to adopt solar powered equipment and waste recycling systems. The rental for sale model, which requires manufacturers to design detachable and recyclable sheet metal components, is being promoted in the European market.

2.Key local elements

- Cost and skills: Developed countries tend to automate (Los Angeles has higher labor costs), while developing countries,such as Southeast Asia, rely on low-cost labor.

- Industry clusters: Los Angeles's automotive and aviation industry clusters driving sheet metal manufacturing toward precision and customization, such as rapid mass production of Tesla panels.

- Policy and logistics: California's strict air pollution control regulations restrict traditional welding processes and promote laser welding. As a major global hub, Port of Los Angeles has shortened the import and export cycles for raw materials and products, but also faces the risk of delivery delays caused by port congestion.

3.Industry Future Trends

Digitization and data-driven approach:

Deploy sensors to monitor device status in real time and perform predictive maintenance to reduce downtime. At the same time, machine learning algorithms are used to balance order priorities and maximize equipment utilization.

Deepening sustainable manufacturing:

- Recycled aluminum Application: Companies Los Angeles use 60% recycled aluminum to produce auto parts and receive tax incentives from the state.

- Zero waste target: Using powder metallurgy technology to produce high performance composites from waste, reducing landfill volumes by 90%.

Trends in regional division of labour:

Offshore returns: Some companies are using their Mexican plants as satellite bases in Los Angeles, utilizing the North American Free Trade Agreement to reduce tariffs while maintaining supply chain agility.

Why invest in sheet metal manufacturing for your project?

Technical advantages of professional sheet metal manufacturer

1.Ultra precision machining capability: ±0.005mm tolerances were achieved using CNC laser cutting, CNC bending, robot welding, etc. (JS case: 95% of projects achieved this accuracy, reducing rework by 90%).

2.Automation and efficiency gains: Fully automated production lines, such as 300T bender unit, shorten production cycles and regular orders are delivered within 1-2 weeks (15% shorter on average JS project cycles).

3.Material and process compatibility: Optimize metal sheet selection, balance strength and cost based on sheet metal specifications, and provide custom finish.

Commercial value of working with sheet metal manufacturers

1.Accelerate product launch

- Rapid prototyping verification (3D printing/CNC sampling) shortens the design iteration cycle and supports a seamless transition from concept to mass production.

- JS undertakes to provide an offer within 24 hours of submitting CAD documents and to prioritize production upon confirmation.

2.Cost controllability and risk avoidance

- One-stop services include design optimization, process validation and delivery to reduce communication costs in outsourced processes.

- JS uses process databases to predict risks (such as white-edged bending of galvanized sheets) and provide solutions to reduce scrap rates.

3.Quality and Compliance Assurance

- The ISO 9001 certification system ensures product consistency by providing material reports, testing certificates and traceability records.

- JS Case: Medical equipment sheet metal parts are FDA-approved, with an error rate of less than 0.02%.

Resumen

Sheet metal fabrication is a complete process of machining metal sheets into high-precision functional components. The core is to control the bending angle and clearance accurately according to the thickness of the metal plate by means of numerical control bending machine and laser cutting equipment to ensure that the finished product tolerance reaches ±0.005mm.

From car panels to medical equipment casings, sheet metal processing not only supports the precision development of modern manufacturing, but also promotes sustainable development through green manufacturing. JS Precision Manufacturing and other enterprises, with ultra-high precision, 98% on-time delivery and a global supply chain, continue to provide reliable solutions across industries to help customers grasp market opportunities.

descargo de responsabilidad

El contenido de esta página es solo para fines informativos. js series No hay representaciones o garantías de ningún tipo, expreso o implícito, se hacen en cuanto a la trampa, la integridad o la validez de la información. No se debe inferir que los parámetros de rendimiento, tolerancias geométricas, características de diseño específicas, calidad y tipo de material o mano de obra que el proveedor o fabricante de terceros proporcionará a través de la red Jusheng. Esta es la responsabilidad del comprador solicite una cotización para piezas para determinar los requisitos específicos para estas partes. Póngase en contacto con nosotros.

JS es una empresa líder de la industria Enfoque en soluciones de fabricación personalizadas. Con más de 20 años de experiencia atendiendo a más de 5,000 clientes, nos centramos en la alta precisión CNC Meckining , Semátil href = "https://jsrpm.com/3d-printing"> 3d Impresión , moldura de inyección , 1.What are the common methods of sheet metal surface treatment? Spray, plating, anodic oxidation, passivation, wire drawing, sandblasting, chrome plating, electrophoretic coating, hot-dip galvanizing, chemical polishing. 2.How to eliminate the curved white edge of galvanized sheet? This can be done by adjusting the bending radius, optimizing mold gap, using special lubricants or precoating with anti-oxidation coatings. Matching process parameters can effectively inhibit the shedding of zinc layer. 3.Why does sheet metal manufacturing require a gauge chart for sheet metal thickness? It can guide the selection of plate processing parameters, guarantee the forming accuracy of different thickness sheets, avoid cracking and rebound deformation, and is the core of optimizing process efficiency and cost control. 4.How does sheet metal processing ensure environmental protection? Green manufacturing and sustainable development using environmentally friendly materials (such as water-based paints), energy-efficient equipment, waste recycling systems, low-pollution processes (such as lead-free soldering), reduced energy consumption and waste emissions in conjunction with ISO 14001 certification standards. JS Team

Nuestra fábrica está equipada con más de 100 centros de mecanizado de 5 ejes de última generación y está certificada ISO 9001: 2015. Proporcionamos soluciones de fabricación rápidas, eficientes y de alta calidad a los clientes en más de 150 países de todo el mundo. Ya sea que se trate de una producción de bajo volumen o personalización masiva, podemos satisfacer sus necesidades con la entrega más rápida dentro de las 24 horas. Elija js tecnología Significa elegir eficiencia, calidad y profesionalismo.

Para aprender más, visite nuestro sitio web: Preguntas frecuentes

Resources