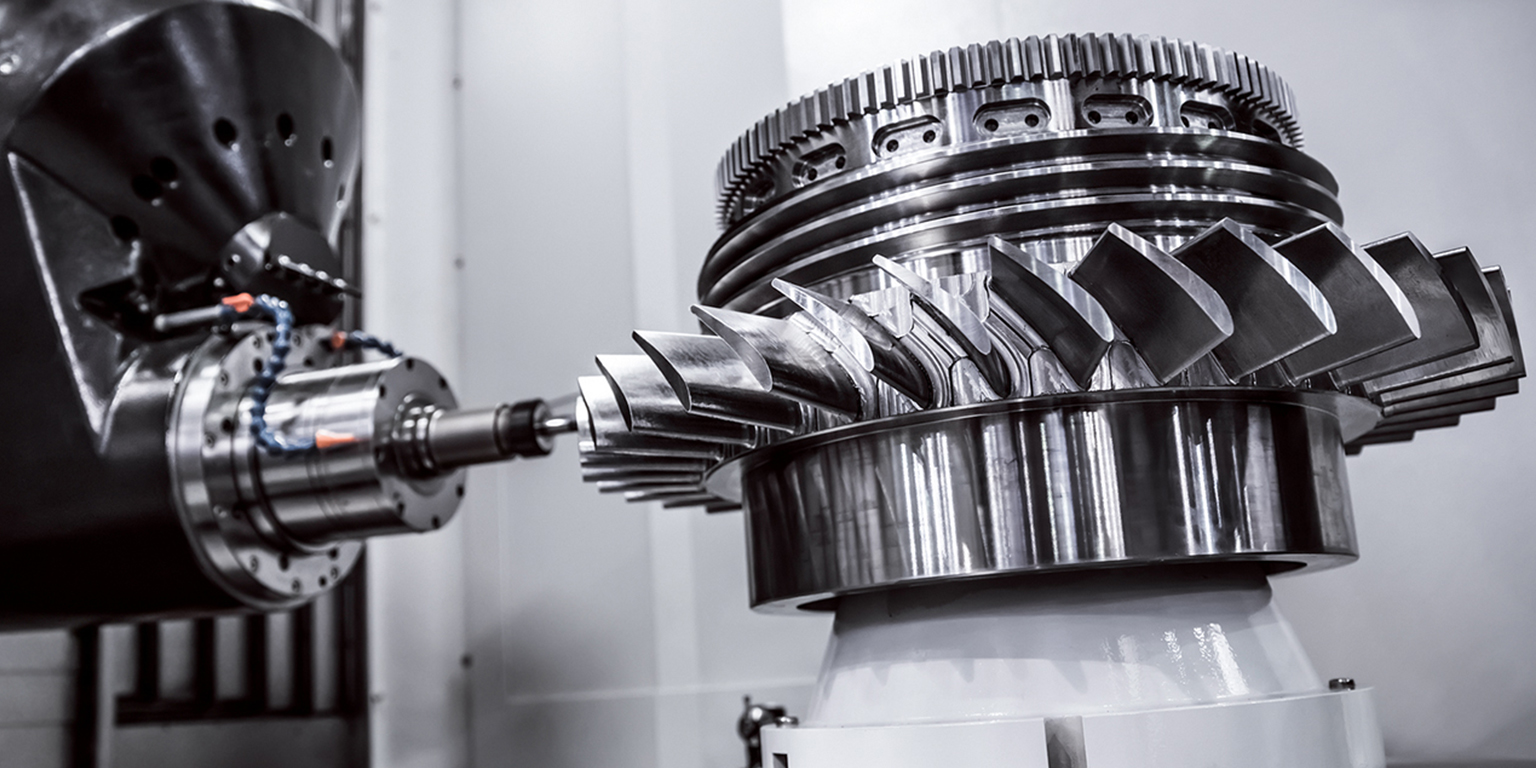

Precision Engineering for Robotics & Automation

JS is your trusted partner for high-precision robotic and automation components. Our solutions are built to enhance system performance, reliability, and scalability, helping you stay ahead in the fast-evolving industry. Get in touch with us today and let’s explore how we can bring your robotics projects to life.

Introduction

Robotics & Automation Services

Advantages & Features

At JS, we deliver innovative and reliable solutions that meet the specific demands of the robotics and automation industry. Discover how we can help you optimize your projects and achieve greater success.

Case Studies

Our robotics and automation manufacturing services have played a pivotal role in several high-profile projects, helping companies push the boundaries of innovation. Below, we showcase some distinct examples that highlight our expertise in producing precision-engineered components that support the evolving needs of robotics and automation:

Quality Control

At JS, we specialize in delivering high-quality robotics and automation components. We take quality seriously, integrating comprehensive quality control measures into every stage of the production process. From the first step to final delivery, we ensure each part meets industry-leading standards of precision, reliability, and durability.

Efficient Production with Early Detection

We understand that delays and defects can significantly impact your operations. To avoid these challenges, we perform in-process inspections at multiple stages during production. This proactive approach helps us identify potential issues early—allowing us to resolve them before they become larger problems. With over 1,000 inspections per month, we reduce defects by 20%, enhancing overall production efficiency.

Final Inspections: Ensuring Excellence

The last step in our process is a thorough final inspection. We understand that precision is non-negotiable, especially for robotics and automation parts. To give you complete peace of mind, we inspect 100% of all parts using state-of-the-art measurement technologies. This ensures that every part is ready to perform reliably in your application—helping us maintain a 98% on-time delivery rate with zero quality returns.

Advanced Tools for Unmatched Accuracy

When it comes to robotics and automation, every dimension matters. To guarantee the highest precision, we utilize advanced tools such as Coordinate Measuring Machines (CMM), optical comparators, and laser scanners. These tools ensure we can measure to the tightest tolerances—up to 0.005mm—for critical components, leading to a 15% improvement in overall measurement accuracy.

Certifications That Speak to Our Commitment

Quality isn’t just a promise; it's backed by globally recognized certifications. Our ISO 9001, ISO 14001, IATF 16949, and AS9100D certifications confirm that our quality management system meets the highest standards. We’ve maintained ISO 9001 certification for over 6 years, consistently passing audits and reinforcing our commitment to continuous improvement.

Contact Us for More Information

Got questions or need assistance with your project? Our expert team is ready to help. Whether you're inquiring about specific requirements or need help with technical details, don’t hesitate to reach out. We’re here to ensure your robotics and automation project is a success.

Got questions or need assistance with your project? Our expert team is ready to help. Whether you're inquiring about specific requirements or need help with technical details, don’t hesitate to reach out. We’re here to ensure your robotics and automation project is a success.

Customer Testimonials

At JS, we specialize in delivering high-quality, precision engineering services that support the evolving needs of the robotics and automation industry. Below are testimonials from some of our satisfied clients who have experienced firsthand the impact of our advanced manufacturing solutions:

Latest News

Stay informed with the latest updates and announcements from JS. Learn about our most recent projects.