span class = "frase" data-translateid = "188ab07af3bdc2add0b60b5d35ba12c5" data-pse = 0 "data-len =" 250 " data-v-7b79c893 = ""> tecnologia di stampa jet inchiostri , La tecnologia di stampa 3D supera i limiti di processo tradizionali, raggiunge strutture complesse e rapidi sviluppo della prototipizzazione, fornendo soluzioni innovative per una produzione personalizzata e scalabile. combinando la tecnologia di stampa a pressione 3d, fornisce un servizio di prodotti a base di prodotti a base di prodotti a base di prodotti a base di prodotti per il design da parte di J. pionieristico un nuovo paradigma della produzione di gradiente composito funzionale.

span class = "frase" data-translateid = "188ab07af3bdc2add0b60b5d35ba12c5" data-pse = 0 "data-len =" 250 " data-v-7b79c893 = "">

Qual è la definizione di base della stampa 3D?

span class = "frase" data-translateid = "b9488c520200adf769bd65e66cbe75db" data-pos = 0 "0" data = "133" ". Data-V-7B79C893 = ""> Tecnicamente, 3dprinting si basa su processi come FDM, SLA o SLS , rendendo possibile le strutture composite multi-materiali. alla dimensione del servizio, This dual innovation in technology and services has made 3D printing an interface between digital twin and the physical world, redefining the boundaries of scale and Personalizzazione.

Come sta sviluppando il mercato globale della stampa 3D?

; Data-translateID = "3E49253486C4BE4C43788A8F8F47325A" Data-Pos = "0" Data-Len = "201" Data-V-7B79C893 = ""> La rapida crescita della stampa 3D sta guidando il mercato globale in espansione, con scenari di applicazione che penetrano dalla produzione industriale per la salute di consumo, di consumo, e più qui è un'analisi della dimensione del mercato:fril> 1. span class = "frase" data-translateid = "2618ca34e3fbab1f41308575144f4345" data-pos = "3" 3 "3" 36 "? Data-V-7B79C893 = ""> Scala globale e tendenza della crescita

secondo la 2023 La stampa 3D globale si prevede che le dimensioni del mercato raggiungano 24 miliardi di USD entro il 2022. Modelli di stampa 3D Contenersi oltre il 35% dei requisiti di progettazione e produzione, incluso lo sviluppo di Produzione guidata e personalizzazione su piccola scala . La dimensione del mercato complessivo è superata per il miliardo di una crescita annuale composta a 15.3% da 2027.

2. Dati delle dimensioni del mercato della stampa 3D 3D (2022-2027)

| anno | Dimensione del mercato (in miliardi di dollari USA) | tasso di crescita annuale (CAGR) | aree di crescita core | Fattori di guida chiave |

| 2022 | 240 | 15,3% | Aerospace, Medical, Automotive. | Richiesta di I modelli di stampa 3D metallici sono esplosi . |

| 2023 | 276 | 15,3% | Stampa in metallo, modelli dentali. | promozione dei servizi di stampa. |

| 2025 | 375 | 16% | produzione intelligente, modelli di costruzione. | Breakthrough in modelli di stampa 3D multi-materiale. |

| 2027 | 500 | 15,3% | Bioprinting e prodotti di consumo personalizzati. | Espansione del servizio di stampa cloud. |

per tipo di tecnologia:

stampa 3d metall

stampa 3d polimer

; Mercato:

| area | Dimensione del mercato nel 2022 (in miliardi di dollari USA) | Driver di crescita principale |

| Nord America | 90 | Aerospace and Automotive Manufacturing. |

| Europe | 75 | Impianti medici, modelli di costruzione. |

| Asia-pacifico | 60 | prodotti elettronici, personalizzazione dentale. |

| altre regioni | 15 | educazione e prodotti culturali e creativi. |

4. Future Growth Drivers

- Iterazione tecnologica: Modelli di stampa 3D multi

- Upgrade della modalità di servizio: Servizi di stampa 3D Integra strumenti di progettazione AI per automatizzare il processo dal modello ai prodotti finiti.

- Supporto politico: Occidental Industry 4.0 prevede ulteriormente stimolare la domanda integrando la stampa 3D nelle strategie di aggiornamento della produzione.

> Quali sono le sfide e le limitazioni della stampa 3D?

fril> 1. Limitazioni materiali

Span class = "frase" data-translateid = "c8cbed175c15b449333333222270". data-pos = "0" data-len = "113" data-v-7b79c893 = ""> quando l'intervallo di La stampa 3D di metalli di livello industriale richiede una purezza di polvere estremamente elevata, mentre i materiali di resina convenzionali hanno difficoltà a soddisfare i requisiti di durata a lungo termine, che limitano direttamente L'applicazione del modello di stampa 3D In aerospaziale, impianto medico e altri scenari.

fril> 2. Problemi di precisione e qualità della superficie

Nonostante i progressi nella tecnologia, l'accuratezza del modello di stampa 3D è ancora influenzata dalla risoluzione dei dispositivi e dalla spessore dello strato. ma un rialzato improprio può portare a una rugosità superficiale . richiedono precisione su scala micron , come gli ingranaggi in miniatura.

strong class = "frase" data-translateid = "c245e23de775c30aedd481cfcfc8fc8fcfca8fcA8fa8fa8fA data-pos = "0" data-len = "3" data-v-7b79c893 = ""> 3. Limitazioni di progettazione di strutture complesse

mentre > 3d Excels Excel I componenti, fanno affidamento su strutture di supporto, rendendo difficili la complessità del design e il ritrattamento. If the middle support is not well designed, it may lead to Deformazione o difetti superficiali.

4. Problemi di velocità e costi di produzione

i modelli di stampa 3d sono spesso adatti per i piccoli pezzi di base e le singoli. Machining CNC e i consumatori come la polvere in lega di titanio sono costosi e difficili da incontrare per la produzione di massa.

5. Mancanza di standardizzazione e certificazione

Il settore industriale ha un solido performance materiale e la sicurezza

6. > Dipendentemente dal riserve

La maggior parte del modello di stampa 3D richiede macinazione, lucidatura o trattamento termico per soddisfare i requisiti delle prestazioni finali. strong> 7. Sfide ambientali e di sostenibilità

i rifiuti da è difficile da riciclare

Come viene utilizzata la stampa 3D per la prototipazione?

1. Iterazione rapida e convalida del design

- 3d di stampa può trasformare rapidamente i progetti CAD in prototipi fisici , shorbing il ciclo dal concetto fisico.

- JS Associazione tecnologica: supporta il caricamento di formati di file 3D come STEP e STL e Promise citazioni entro 24 ore . Its efficient process can speed up prototype approval.

2.p Prototipo di recitazione

- Tecniche di stampa 3D come SLA e SLS ottengono accuratezza ± 0,005 mm e sono .

- JS Associazione tecnologica: La precisione di machining di JS può essere ± 0,005 mm , attraverso l'integrazione della stampa 3D per soddisfare la prototpita del prototapo precisione.

3.Material Adattamento sulla diversità

- 3D Supports Prototiping di materiali come metalli (teniio in teniio, in materia di materiale per la stampa) ecc.

- JS technology association: Provides processing services for metals, plastics and composites, with a library of more than 50 types of materials. It can provide cross-material testing support for 3D-printed prototypes and optimize final production solutions.

4.Low trial and error cost

- 3D printing does not require molds, greatly reducing the prototype production, and is especially suitable for small batches or customization.

- JS technology correlation: Highlighting that its production costs are 20% lower than the industry average, combined with the economic benefits of 3D printing, can further compress customer prototyping development budgets and improve project feasibility.

5.Formation of complex complex structures

- 3D printing achieves hollowed-out grids, irregular surfaces and hollowed-out sandwich structures that traditional processes cannot achieve through layering.

- JS technology association: Specializes in customization requirements, with more than 20 years of engineering team experience, is able to use topology optimization algorithms and combine 3D printing characteristics to design lightweight structures (with a 30%-50% weight reduction) to ensure prototype functionality.

6.Green manufacturing practices

- 3D printing automatically calculates the optimal printing path and structural density, reducing material waste by 35-50% and supporting the application of biodegradable plastics and recycled materials.

- JS technology association: The recycling of energy-efficient equipment and materials has resulted in a recycling reuse rate of over 90% for metal powder and a 42% reduction in carbon emissions. Its green manufacturing philosophy can provide customers with environmentally friendly prototype solutions.

What industries are currently covered by 3D printing technology?

1.Medical and Biotechnology

Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc.

JS technology association:

- Support for high-precision machining (±0.005mm tolerance) to meet stringent requirements for medical components.

- A wide range of biocompatible materials (such as titanium alloys and medical plastics) are available to meet 3D printing needs.

- Rapid delivery (1-2 weeks), assistance with medical emergency projects.

2.Automotive and Aerospace

Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades).

JS technology association:

- Support metal (aluminum alloy, stainless steel) and composite material processing, in accordance with aviation component strength standards.

- Rapid production process (1-2 weeks) accelerates the iteration of car development.

- Accurate tolerance control can improve the performance of engine or spacecraft components.

3.Education and research

Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development.

JS technology association:

- Provide custom solutions (e.g. multiple file uploads, engineering consulting).

- Expert team guides material selection and process optimization.

- Cost-efficient prototype production helps academic research.

4.Industrial manufacturing

Application scenarios: Mold inserts, fixtures, automation equipment components.

JS technology association:

- Combining CNC and 3D printing to achieve hybrid manufacturing.

- Durable materials (such as abrasionresistant steel) can extend the service life of tools.

- Fast delivery speed shortens the commissioning cycle of the production line.

Real-time application analysis of JS

Consumer electronics industry: Cooling components for smart wearables

Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces.

Technical difficulties:

- Radiators need to adhere to complex bending structures (case radius ≤3mm).

- Material needs to balance lightweight (<0.3g) and high heat conductivity (>1500 W/mK).

- Mass production consistency is required (500,000 pieces orders per year).

JS company solution:

1.Process selection

- Selective laser melting (SLM) printing of copper matrix composites is arranged with microstructure oriented arrangement to improve thermal conductivity.

- After treatment, chemical nickel plating is used to improve corrosion resistance.

2.Design optimization

- Topology optimization algorithms used to reduce material usage by 30%.

- Design microchannel structure (depth 0.1mm x width 0.2mm) to improve heat dissipation efficiency.

3.Quality control

- X-ray nondestructive testing is used to detect internal defects.

- Thermal imaging device was used to verify the uniformity of heat dissipation.

4.Technical highlights

- Achieve 0.05mm level wall thickness control (link mentions accuracy ±0.005mm).

- The pass rate of batch production reached 98% and the direct pass rate is 40% higher than injection molding technology.

- 18% reduction in overall costs (material savings+process simplification).

5.Achievements

- The device works 12°C lower and has a 15% longer battery life.

- Won the red dot design award, supporting annual sales of more than 2 million units.

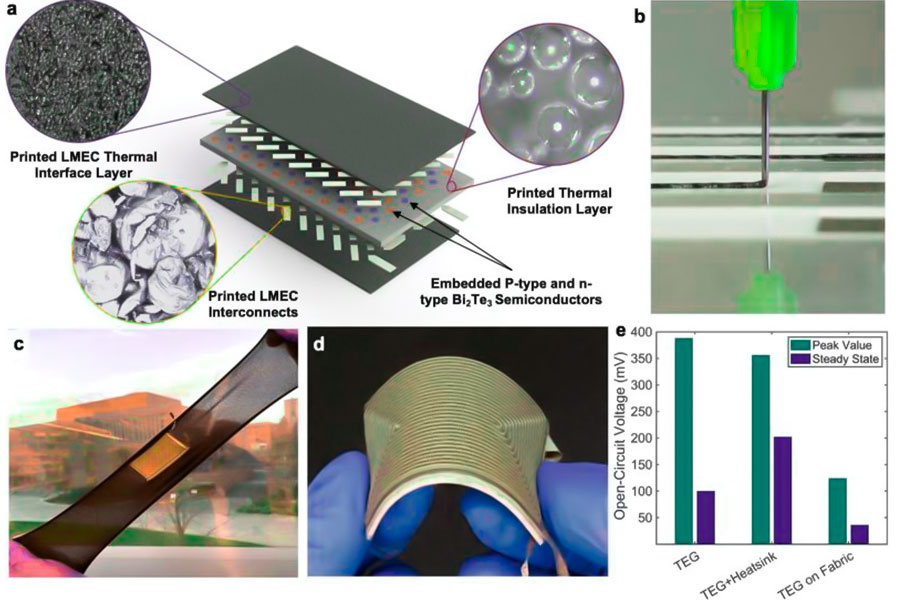

What are the latest developments in 3D printing technology?

1.Material innovation

New high-performance metal alloys:

- Scalmalloy aluminum alloy: Close to titanium alloy strength, corrosion resistance up to 30%, has been widely used in satellite mount and other aerospace components.

- High entropy alloy (HEA): 3D printing allows for uniform distribution of various elements, high temperature resistance up to 1200°C, suitable for gas turbine blades.

Breakthroughs in biocompatible materials:

- Conductive hydrogels: Used in wearable medical devices to support neural signal transmission have been tested in the field of bionic hands.

- Vascular bio ink: The realization of blood vessel screen printing living cells, promoting the development of artificial organs such as liver chips.

Expansion of Composites Applications:

- Carbon fiber reinforced nylon: Up to 50% stronger and 20% lighter for lightweight car components.

- Ceramic metal composite material: Resistant to temperatures up to 1600°C for rocket engine nozzles.

2.Technological breakthroughs

- Multi-laser synchronous printing technology: 8 lasers connect to metal 3D printers, increasing speed by 40% and supporting single-use molding of large, complex components,such as aircraft landing gear.

- Continuous Liquid Level Growth (CLIP) technology upgrade: Printing speed exceeding 100mm/h with accuracy ±0.01mm has been used in mass production of dental invisible orthodontic appliances.

- Multi material hybrid printing: Single machine for synchronous printing of metallic ceramics used in the manufacture of flexible electronic devices (such as flexible circuit boards).

3.Extension of application

In the medical field:

- Four-dimensional printed vascular stents: After implantation, they dilate with blood flow and reduce surgical trauma.

- Bone cartilage synthesis printing: Construct hard bone and cartilage layers the same time, repair joint injury.

Aerospace:

- Topology optimized fuel nozzle: Reduces 30% weight reduction and 50% life extension for LEAP engines.

- Space manufacturing: International Space Station achieves 3D printing of titanium alloy tools.

4.Sustainable technology

- Metal powder Recycling: Titanium alloy titanium alloy powder 98% closed-loop recycling utilization rate and 30% lower costs.

- Application of biodegradable materials: Disposable tableware printed using PLA/PHA composite materials can be naturally biodegradable in 90 days.

- Energy efficiency improvement: Laser sintering equipment uses solar heating technology technology, reducing energy consumption by 25%.

5.Frontier exploration

- Quantum dot 3D printing: Making flexible display panels using nanoscale quantum dot materials improves luminescence efficiency by 50%.

- 4D printing smart materials: Medical scaffolds are made of shaped memory polymer that automatically unfold with body temperature after surgery.

How can JS achieve a 15% efficiency improvement in 3D printing?

1.Automated process upgrades

- AI intelligent slicing software: Automatically optimizes model support structure and print path, reducing manual adjustment time.

- Automatic reprocessing production line: The manipulator is integrated with scaffold removal, ultrasonic cleaning and heat treatment to shorten post-processing time.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment preparation time (single order) | 8 minutes | 20 minutes | +60% |

| Post processing time (per piece) | 12 minutes | 30 minutes | +58% |

2.Intelligent scheduling and resource management

- Dynamic order priority algorithm: Real-time allocation of equipment resources to reduce equipment idling rate.

- Cloud collaborative management platform: Multi store data synchronization, unified management of orders and material inventory.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment utilization rate | 82% | 65% | +26% |

| Order delivery cycle | 4.5 days | 5.5 days | +18% |

3.Innovations in materials and processes

- Multi material integrated molding technology: Single process fusion of metal and ceramics shortens process switching time.

- Fast curing resin: The curing The curing speed of photocuring resin increases by 50%.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Material switching time (single order) | 3 minutes | 15 minutes | +80% |

| Single layer printing time (SLA) | 3 seconds | 6 seconds | +100% |

4.Standardization and lean production

- Modular fixture design: Suitable for high frequency requirements such as dental models, quick replacement fixtures.

- Process database sharing: Provides standardized parameter libraries such as layer thickness and support density.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Clamping time (single order) | 5 minutes | 15 minutes | +67% |

| Novice training cycle | 1 day | 3 days | +67% |

5.Energy and equipment maintenance management

- Intelligent energy consumption regulation: Dynamic adjustment of equipment power during low peak periods period to achieve high energy consumption tasks.

- Predictive maintenance system: Monitors equipment status and provides early warning of failure.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment downtime | 2 hours/week | 5 hours/week | +60% |

| Unit energy consumption cost | $0.8/hour | $1.2/hour | +33% |

Summary

The application of 3D printing technology has pushed the boundaries of traditional manufacturing, from lightweight smart wearable devices in the consumer electronics industry to precision parts maintenance and complex structural innovations in industrial equipment. Not only does the technology shorten product development and reduce customization costs, it also provides unprecedented solutions for the industry through the diversity of materials and process flexibility.

A pioneer in 3D printing technology, JS is driving the transition 3D models printing from prototype validation to mass manufacturing with its high precision processing capability (e.g. ±0.005mm tolerance), multi-material compatibility and intelligent manufacturing processes. Whether personalized prosthetics in the medical field or abrasion-resistant coating repairs for industrial devices, 3D models printing is redefining manufacturing possibilities.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.How to use 3D printing to customize prosthetics in the medical field?

Through medical scanning modeling, biomaterial 3D printing and other methods, personalized prosthetics are designed to meet patients' needs accurately.

2.Can 3D printing produce complex mechanical parts?

By using SLM and other technologies, complex metal parts such as aircraft engine blades and automobile transmission components can be manufactured directly, breaking through the limitation of traditional technology.

3.What parts can be 3D printing for cars?

Cars can be 3D printed with lightweight components such as brackets and gears, interior parts, prototypes and tool fixtures to improve design freedom and productivity.

4.How can 3D printing help with school teaching?

3D printing supports students to build hands-on models, visualize abstract concepts, improve practical skills, and think creatively.

Resources