In modern manufacturing industrymis one of the core technologies for shaping product shapes. As the most influential process, As an industry-leading company,JS has been deeply involved in plastic molding for more than 20 years.Whether optimizing molding designs to reduce production costs or choosing silicone molding materials to improve product performance to meet specific needs, JS drives manufacturing upgrades through technological innovation to help customers stand out in a competitive market.

What is injection molding?

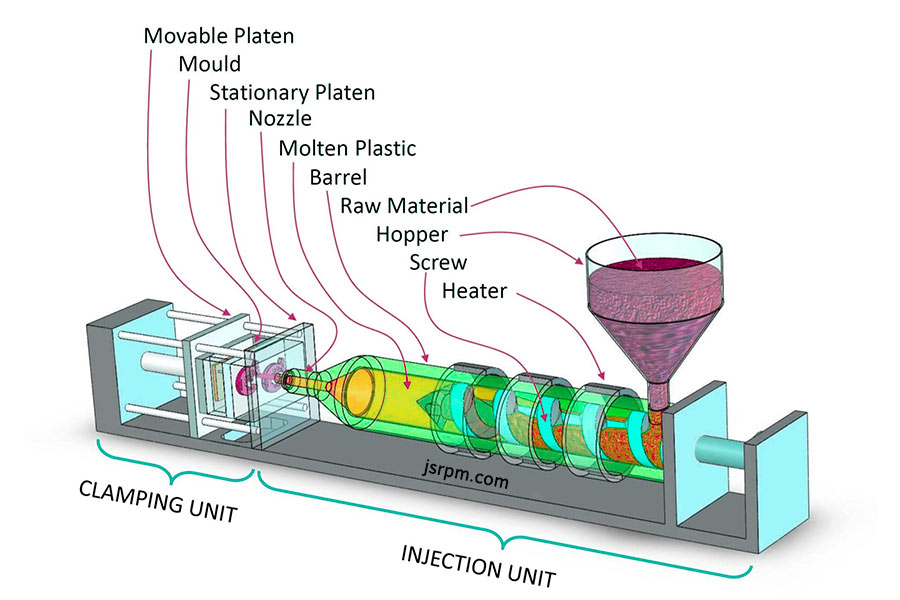

Injection molding is an effective manufacturing technologyin which particles or liquid plastic/rubber materials are heated and melted, injected into mold cavity under high pressure, cooled and solidified into various plastic molds. Widely used in automotive parts, medical equipment, consumer electronic equipment and other fields. It has high precision and large production scales and has become the core technology of modern plastic processing.

What are the core advantages of injection molding?

1.Effectivemass production, fast delivery

Modeling injection technology involves the injection of molten material into the mold at high temperatures and pressures, resulting in hundreds of thousands to thousands of plastic molds once.It is especially suitable for mass production and greatly shortens delivery cycles.

2. The structure is accurate and complex, and labor costs are reduced

From micrometer-level precision parts to complex components embedded in parts and surfaces,moldinginjection technology relies on Die Precision (±0.01mm) to meet design requirements, eliminating secondary treatments and reducing manual intervention and material waste.

3. Material-rich material selection to meet various needs

Supports the molding of injections of thermoplastics (such as ABS, PC), thermosetting resins, liquid silicones and various other materials. It can be customized by special features such as wear resistance, temperature resistance and biocompatibility, such as meeting the needs of high-end areashealth care and consumer electronics.

What are the core elements of injection molding design?

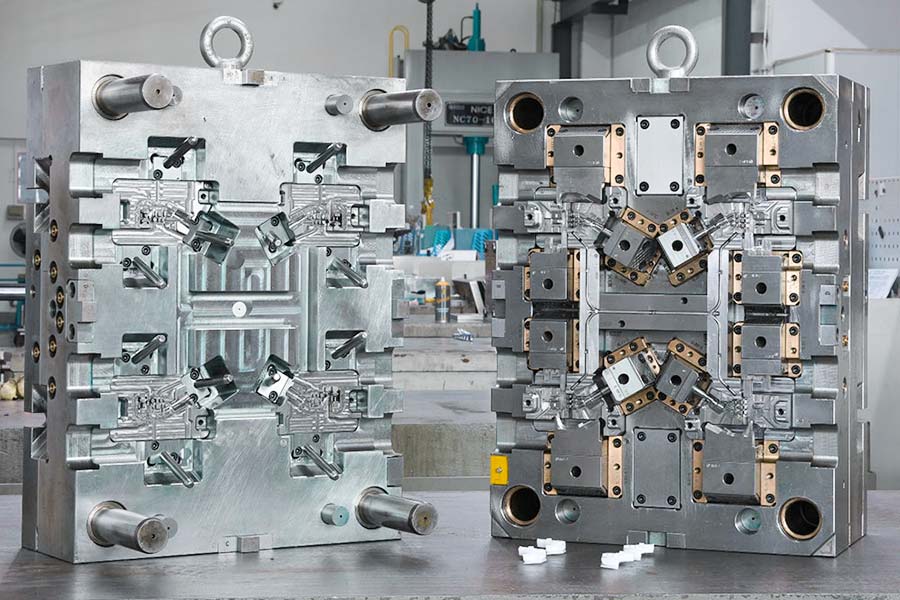

Plastic mold design is the key to successPlastic molding. It is necessary to consider mold structure, material selection and process parameters:

| Core elements | Key content |

| Mold Structure |

|

| Material selection |

|

| Process parameters |

|

| Product design optimization |

|

| Quality Management |

|

How are injections made?

1. Design plan: exact matching

The injection mold design should conform to the characteristics of the product drawings and the plastic material. JS engineers use CAD softwarecomplete molded plastic design, ensuring uniform wall thickness (1-4mm), reasonable draft angles (1-3°), and optimizing gate position to reduce shrink marking. For example, JS's focus is on the characteristics of liquid silicones with a thin wall design of 0.02mmin precise components such as medical catheters.

2. Material selection: adaptation process and cost

mOld steel should be formed according toPlastic in the mold:

- Thermoplastics (such as ABS, PC): P20 or SKD11 steel, high temperature resistance, high hardness.

- Liquid Silicone: Made of H13 steel, it is corrosion-resistant and has a smooth finish, reducing the risk of silicone sticking to mold.

JSextends the service life of death by more than 30% through useJSRS pecialized mold steel.

3. Processing and manufacturing: high-precision molding

Rough processing: The main contour is completed through numerical control.Precise machining: Accurate slow-wire cutting of ±0.005mm.

- Surface treatment:For transparent plastic molds, place the polish to <0.05 μm to remove burrs.

- JShas a 4000T-classlarge CNC equipmentsupports complex inserts and multi-cavity molds for integrated processing.

4. Assembly and debugging: Verification function

- Mold assembly: Insert sliders and pop-up mechanisms accurately to ensure synchronous motion.

- Test mold:IPlastic plastics, Verify molding cycles (for example 20-60 seconds per piece) and product dimensional tolerances.

Problem correction: Adjust the exhaust tank or cooling water circuit according to the test mold results, and optimize warping and bubble defects.

5. Maintenance and Upgrade: Extend service life

- Periodic maintenance: Clean the mold cooling water circuit,repair the polished surface.

- Intelligent modification: Install temperature sensor and IoT module to monitor mold status in real time.

- Rapid change: is used in a variety of productions, and uses a rapid mold insertion design to reduce the time of change of mold to less than 15 minutes.

- JSprovides a lifetime warranty for molds, supporting remote diagnosis and rapid maintenance.

What key indicators should be considered in the selection of injection molding materials?

In injection molding, the selection of materials directly affects the performance, production efficiency and cost of the product. The following are the key indicators to be considered, and JS company's technical practice suggestions in the field of plastic molding:

1.Mobility

- The fluidity of the material determines its efficiencyinjection-molding.High elastic materials (such as liquid silicone JSR) tend to fill complex structures, but can cause burrs, and low elastic materials (such as high density polyethylene (HDPE)) require high injection pressure.

- JS ensures stabilityInjection molding process optimizes material formulation and mold design, such as adding exhaust slots, and is particularly good at handling thin-walled components of low-flow materials, such as Medical catheters.

2.Shrinkage

- The shrinkage of the material after cooling and curing directly affects the dimensional accuracy.The shrinkage rate of liquid silicone gel is only 0.1-0.3%, which is suitable for high-precision medical equipment.

- JS Company compensates for shrinkage through mold design and controls the tolerance of product size to ±0.05mm.

3.Thermal stability

This material is subjected to high injection molding temperatures (e.g. 280°C of PET).JS is equipped with a high-temperature injection molding machine (up to 400°C) that supports processing of high-temperature resins (such as POM, ASA) and predicts the risk of thermal degradation to avoid warping or discoloration.

4.Mechanical properties

- Tension strength: Engineering plastics (such as PCs) can reach up to 60MPAAutomotive components. The stretching rate of liquid silicone is more than 300% of the flexible seal.

- Shockability: Strengthen the TPU material with glass fibers (e.g. PA66 + GF30) to increase its resistance to 50% to make it suitable for fragile items such as Mobile Box.

5.Cost and Resilience

- Low Cost Materials: ABS and PS for quality production.

- Environmental Materials: (Lacertic Acid and PCR Recycled Materials can reduce carbon emissions by more than 30%.JS uses recyclable materials to promote injection molding to help customers achieve carbon neutral goals.

How to optimize product structure and production efficiency through injection molding design?

Structural Design Optimization

1.Wall thickness uniformity design: CAE flow analysis for optimizing wall thickness distribution and avoiding shrinkage marks and stress concentrations.For example, optimizing the wall thickness from 3 mm to 2.5 mm can reduce the cooling time by 30%.For complex components, thicken them with rib structures instead of solids.

2.Demould slope and drainage design: Recommended internal and external drainage angles ≥0.5°.Gradually conduction is used in deep cavity structures to reduce the disengagement resistance.JS's precision EDM emission processingcan handle sharp edges up to 0.02mm.

3. Optimization of casting system: Using a heat flow system (JS company supports needle valve thermal Nozzle structure) is used to reduce gate residues and increase yield.For example, using an invisible door inside a car can reduce burrs by up to 40%.

Process Parameter Optimization

1.Dynamic control of maintaining pressure curve: JS's closed-loop control system is used to control fixed pressure in real time.

2.Cooling system optimization: According to the analysis of the mold flow of JS company mold flow, the form of cooling water loop is designed to shorten the cooling time by 20%-30%.Display periodAutomotive component housinghas been reduced from 45 seconds to 32 seconds.

What are the key application areas of JS injection molding?

1.Automotive industry

- Purpose: A lightweight design bumper, panel, engine assembly, ETC.

- JS Case: New energy vehicle company's customized battery cover reduces the ebb rate from 8% to 1.2% by optimizing the door layout, saving more than $1 million per year.

2. Consumer Electronics Industry

- Purpose: Precise structural components such as phone boxes, headphones and smartwatch boxes.

- JSCase: 7-day delivery, ultra-thin telephone box mold (only 0.3mm thick), supports PC+TPU dual-color injection molding, 98% pass rate.

3. In the medical field

- Purpose: syringe BARRE, infusion tube accessories, cardiac stents, medical catheters and other high hygiene components.

- JSCase: Biodegradable medical suture anchors have been developed for multinational medical device companies, which have PLA and TPU dual material injection molding, and the product size tolerance is ±0.2mm to help customers capture the minimally invasive surgery market.

4.Industry and Mechanical Components

- Purpose: gears, bearings, ocean and other wear-resistant and high temperature components.

- JSCase: POM material injection molding of highly rigid gears instead of metal parts reduces cost by 30%.

What injection mold solutions do JS have?

1. Multiple Material Injection Molding Solution

- With the combination ofusing precision design, the combination of PC + TPU, ABS + PC can form a soft hard-bonded structure, and the material utilization will increase by 30% and the cost can be greatly reduced.

- Multi-cavity mold design (up to 20 cavity) balances cooling efficiency and exhaust performance.

2. Precise mold design and manufacturing

- High precision machining:Mold machining accuracy is ±0.005mm, supporting injection molding with 0.1mm thin walls (for example, precision instrument housing).

- The cooling water loop is as follows: the 3D printed water loop covers complex cavity, increases cooling efficiency by 30%, and reaches a twisting deformation rate less than 0.5%.

- Automatic injection molding:can be embedded with an accurate ±0.02mm into the overall visual positioning system, metal inserts (such as screws and chips).

3. Erosion prototype and small and medium batch production

- 3D printing test mold: Resin prototypes are delivered within 72 hours to speed up custom product verification.

- Rapid Prototyping System: Modeling in 15 minutes, suitable for small and diverse orders.

- Flexible Manufacturing Unit: Set injection molding, test, packaging in one, 7 working days to complete small and medium-sized orders.

Summary

As the cornerstone process of modern manufacturing, injection molding continues to promote innovative development in the automotive, electronics and medical industries, with its advantages of high efficiency, accuracy and adaptability. Suitable for precise medical catheters and lightweight automotive components, from mold design to material selection (e.g. ABS, PC, PA, etc.) and precise control of process parameters (pressure, temperature, insulation time), injection molding balances production efficiency and product performance, and acts as a core bridge between design and quality production.

JSfocuses on injection molding technology innovation, optimizing material selection, mold structure and process parameters. Whether it is pursuing extreme efficiency, complex structures or green manufacturing, JSprovides customizable solutionsto ensure that each plastic product has quality, value and vitality.

Disclaimer

The contents of this page are for informational purposes only.JS Serieshas no representation or warranty, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Jusheng Network. It is the buyer's responsibility to require a part quote to determine the specific requirements of these parts.Please contact us for more information.

JS Team

JS is an industry-leading companyfocused on custom manufacturing solutions. With more than 5,000 customers’ experience, we focus on high-precisionCNC machining,sheet metal manufacturing,3D printing,injection molding,metal stamping, and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. ChoosingJS technologymeans choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQ

1.How to choose injection molding and CNC processing?

Injection molding is suitable for a large number of complex parts. CNC is suitable for small batches, high precision or metal materials.

2.What is the difference between silicone injection-Molding and ordinary plastic injection molding?

Silicon requires liquid injection and vulcanization to make the product softer and more environmentally friendly, but at a higher cost. Regular plastic is melted and injected directly, then naturally cooled and molded.

3.What are the advantages of injection molding?

Production efficiency, large-scale production of shared mold costs, very low unit cost, high dimensional accuracy, smooth surface, a wide range of applications, suitable for large-scale production. The comprehensive cost efficiency is excellent and is the choice of the quality production method for plastic products.

4.Why do you need to cool during injection molding?

After injecting molten plastic into the mold, it needs to be cooled and solidified to maintain its shape for easy removal. Plastics are liquids at high temperatures and must be cooled to retain their shape in the mold and avoid product distortion and warping. After cooling, the plastic becomes more rigid, making it easier to remove.