span class =" sentence "data-translateid = 576133361d3266b52a data-pos = "0" data-len = "166" Data-V-7B79C893 = ""> في مجال النماذج الإيجابية السريعة ، اختيار المواد المحددة للمنتج.

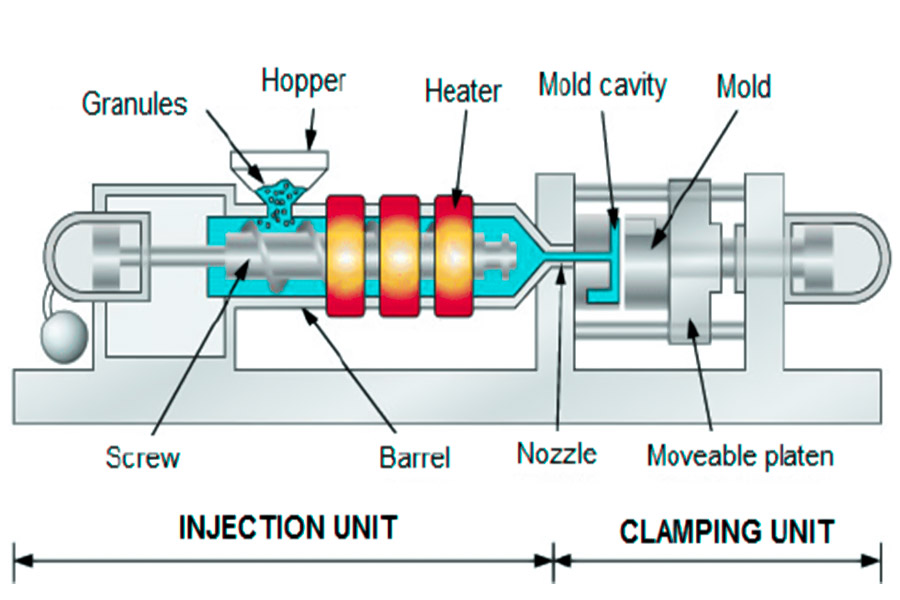

span class =" sentence "data-translateid =" fe053bd7906f562423e4e4e0d2. data-pos = "0" data-len = "368" data-V-7B79C893 = ""> الهيكل الدقيق لتصميم القولبة لتحويل المواد الخام إلى أشكال معقدة لتحقيق الكفاءة العالية والاتساق . conduct stream techans of plastic ultug الأجزاء ذات الجدران الرقيقة أو الإنتاج الضخم والتي يصعب الوصول إليها في التصنيع التقليدي من خلال عملية موحدة. تشمل الخطوات الرئيسية لتصدع الحقن ذوبان المواد ، وصوفية الإصابة عالية الضغط. 1. Data-Len = "31" Data-V-7B79C893 = ""> صب الحقن الحراري SPAN CLASS =" Sectence "Data-TranslateId =" BB5B36D56DE8BEE088353FA482D " data-pos = "0" data-len = "179" Data-V-7B79C893 = ""> polymers thermoplastic يتم تسخينها إلى حالة من الصخور ، JS لديها قدرة التحكم في التسامح ± 0.005 مم وقادرة على إنتاج بنية تلقائية معقدة ± 0.005 ملم. تقنية صب سريعة يتم تكييفها بالكامل مع خصائص الانصهار المتكررة للمواد الحرارية ، مما يقلل بشكل كبير من تكاليف الإنتاج. span class =" sentence "data-translateid = 8a1921e52a9b03e9735. Data-pos = "0" data-len = "113" Data-V-7B79C893 = ""> Thermosetting Plastics تخضع لتفاعلات كيميائية لا رجعة فيها وتتوحد تحت درجة حرارة عالية وضغط.

ما هي الأنواع الأساسية من صب الحقن؟

ما هي الأنواع الأساسية من صب الحقن؟

JS لديها أكثر من 50 تجربة معالجة ، ودعم تشكيل Resinoloy Resinolo.

3. مطاط السيليكون السائل

span class =" sentence "data-translateid =" e391319f8e3e3c4096ba data-pos = "0" data-len = "138" Data-V-7B79C893 = ""> يتم حقن مطاط السيليكون السائل في قوالب عن طريق صب الحقن ثم المصبوب بواسطة الفلك المنخفض درجات الحرارة.

js أصبح مورد أساسي لـ lsr ablem abiseets و sealace multinational medicial taugh ta multinational medical. ± 0.005 مم وعملية نظيفة متوافقة مع معايير FDA.

SPAN CLASS =" SENENCE "TRANSLATEID = data-pos = "0" data-len = "171" Data-V-7B79C893 = ""> يتحقق التكامل متعدد الوظائف عن طريق وضع طبقتين أو أكثر (مثل المصفوفة البلاستيكية الصلبة+طلاء للصفاء الناعم) في نفس القالب من خلال القولات الوسيطة.

span class =" sentence "data-translateid =" ff70aa2452fc455545454554545455454554554545454 data-pos = "0" data-len = "172" data-V-7B79C893 = ""> خط الإنتاج التلقائي لـ js مكونة من مجموعة واسعة من المواد ، مما يدل على ما يتكامل. الدروع.

data-translateid = "d52c6e81398cedb0e59f2e12acbec8a5" data-pos = "3" data-len = "33" data-V-7B79C893 = ""> الجمع بين عمليات حقن الصب لمادة أو أكثر ، مثل البلاستيك الصلب والمطاط الناعم ، من أجل التكامل الوظيفي من خلال فهمات متعددة أو قالب بالجراحة ، يستخدم عادة في الهياكل المعقدة للإلكترونيات الاستهلاكية والأجهزة الذكية القابلة للارتداء.

ما هو الفرق بين صب الحقن البلاستيكي وقولبة حقن السيليكون؟

يستخدم مصداقية حقن البلاستيك بشكل رئيسي لارتفاع درجة حرارة الذوبان من البلاستيكات لتشكيل منتجات صلبة و

مقارنة الأبعاد

صب بلاستيك

صب السيليكون

نوع المادة

lothoplastics (مثل ABS ، PE) أو البلاستيك الحراري (مثل راتنج الفينول).

يتم ترسيخ مطاط السيليكون السائل (LSR) بواسطة عملية صب السيليكون المطاطية.

درجة حرارة العملية

plastics molten في درجات حرارة عالية (150 درجة مئوية-300 درجة مئوية).

vulcanization في درجات حرارة منخفضة (60 درجة مئوية إلى 150 درجة مئوية).

متطلبات القالب

تتطلب قناة التدفق نظام التبريد مع مقاومة درجة الحرارة العالية ، ومقاومة الضغط والدقة.

معالجة السطح المضاد للالتصاق (مثل طلاء PTFE) ، قناة تدفق واسعة لمنع انسداد LSR.

حقول التطبيقات

أجزاء السيارات ، القشرة الإلكترونية ، السلع والمنتجات الصلبة الأخرى.

سيناريوهات الطلب المرنة مثل القسطرة الطبية ، والأختام ، والأجهزة القابلة للارتداء ، وما إلى ذلك (اعتمادًا على دقة صب السيليكون).

Post Processing

إزالة بدون علاج.

اختياري انخفاض درجة الحرارة الثانوية هو خيار لتحسين الأداء.

التكلفة والكفاءة

التكلفة المنخفضة ، مناسبة للإنتاج الضخم.

سعر وحدة المواد مرتفع ، ولكن يتم دعم تخصيص الدُفعات العالية وتخصيص الدفعة الصغيرة (على سبيل المثال 0.005 ملم).

SPAN style =" font-size: 17px ؛ data-translateid = "9A3DDE8472A4725960E0B0B4B9A3D4DF" data-pos = "0" data-len = "3" data-V-7B79C893 = "" "

SPAN-V-7B79C83 = "

span data-V-7b79C893 = ""

span style = "font-size: data-translateid = "13d6e05fc5a80b9b0b07de3296e9a13b" data-pos = "0" data-len = "3" data-v-7b79c893 = "" sentence>

وفقًا لتكنولوجيا التصنيع الدقيقة لشركة JS ومتطلبات تدبير الحقن الدقيقة ، فإن المعدات والتقنيات الرئيسية المطلوبة هي كما يلي: 1.I آلة صب الإشارة

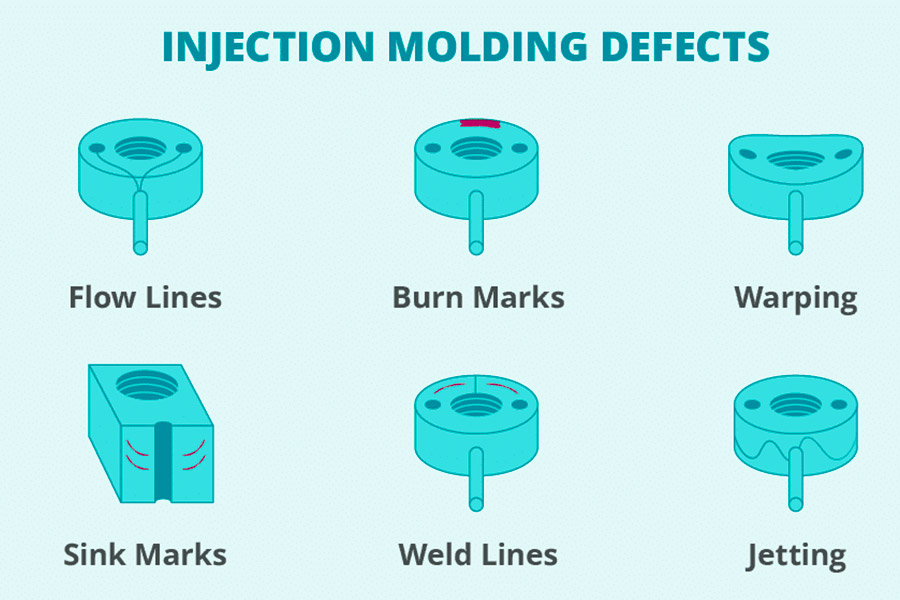

3.Advanced Testing Equipment Unit 4.Automated production systems 5.Special Material Processing Equipment JS company combines micro-injection molding machines, wire cutting equipment and Moldex3D simulation system to form a full-chain technology loop from molding design to precision plastic molding. Typical manufacturing case of micro parts: precision gear injection yield of 0.5mm diameter was 99.2% and dimension tolerance was controlled to ±0.003mm, demonstrating the progressiveness of the equipment system. 1.Material selection and compatibility treatment 2.Mold design and manufacture 3.Injection molding process parameter control 4.Interface integration technology Mechanical interlock design: Design of a concave or inverted structure in a die to improve bonding strength through physical interlocking. Chemical Adhesives Precoating: Special adhesives are sprayed on the surface and cured by injection molding with high temperature activation to achieve molecular level bonding (suitable for dissimilar materials). 5.Quality inspection and إعادة المعالجة In the process of injection molding, due to the influence of material properties, process parameters and equipment accuracy, the following technical problems are often encountered: 1.Material shrinkage control 2.Warp and twist 3.quality defects 4.Multi cavity mold balance 5.Risk of material degradation JS company's technological advantages Typical Case Reference Actual results: Injection-molding is the core technology of modern industry. By melting and solidifying molding plastic material, the production of simple rigid member to complex elastic member is diversified. Whether it is the efficient mass production of thermoplastic or the precise flexible molding of liquid silicone, its process adaptability covers many fields such as automobile, medical treatment and electronics. With its ±0.005mm precision mold design multi-material compatible processing, and automated production line integration integration capabilities JS Company continues to push the boundaries of precision and efficiency injection molding field, providing global customers with one-stop solutions from prototype development to mass production, enabling industry transformation and upgrading for high value added and sustainable development. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.The influence of mold temperature on the quality of injection molded parts? The mold temperature is too high, which leads to deformation of injection molding, and the surface roughness or internal stress concentration. Accurate adjustment to material characteristics (e.g. 50-80°C for ABS) are required to ensure size accuracy and appearance quality. 2.What are the commonly used types of injection molding machines? Commonly used injection molding machines types are plunger type, screw type and screw pre-formed plunger type. Among them, screw plastic has become mainstream for its efficiency and energy saving and has been widely used in the mass production of plastic products. 3.What problems can high injection pressure cause? Excessive injection pressure can lead to flash flooding (overflow), increase mold wear, and even lead to deformation or cracking of the product, as well as increased load and energy consumption of the equipment. 4.How to choose suitable injection molding materials? Consider the the product's intended use (PC strength, TPU elasticity), processing temperature and costs such as PP's high temperature resistance, TPU's flexibility, ABS's balance performance and cost. Acrylonitrile butadiene styrene

ما هي المعدات المطلوبة لعلم حقن الجزء الصغير؟

How to achieve the combination of multiple material injection molding?

What are the common difficulties in injection molding?

Technical difficulties

Industry standard solutions

JS Innovative Solutions

Material Compatibility

Compatible with ordinary plastics only.

Supports more than 50 specialty engineering plastics (such as PEI, PPS, etc.) and provides material modification services.

Formation of microstructures

The minimum feature size is 0.5mm.

Mirror etching mold technology used to achieve batch production of 0.2mm fine texture.

Complex Embedded Assembly

Manual positioning error ≥0.1mm.

Automated embedded positioning system with accuracy ±0.02mm were used.

Environmental compliance

Single material recycling.

Innovative multilayer compound structure separation technology enables efficient regeneration of PET/PC and other hybrid materials.

Fast delivery

The standard cycle is 2-4 weeks.

Digital twin technology reduces the test run time to 7 days and responds to emergency orders within 48 hours.

How can JS reduce injection molding production costs by 20%?

Summary

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.comFAQs

Resources